HP LaserJet 5000, 5000 N 5000 GN Printers

HP LaserJet 5000, 5000 N, and 5000 GN Printers

Copyright Hewlett-Packard Company

Contents

Printer Operation

Functional Information

Removing and Replacing Parts

Index

Contents

Printer Description

Overview

Printer Features

Printer Features

2Printer Description

Paper Path

4Printer Description

Identification

Model and Serial Numbers

Site Requirements

6Printer Description

2Printer Dimensions, HP LaserJet

Space Requirements

3Printer Dimensions, HP LaserJet 5000 N/5000 GN

8Printer Description

Printer Weight without toner cartridge

4Printer Dimensions, HP LaserJet 5000 with Accessories

Environmental Requirements

Acoustic Emissions Per ISO Printer State Sound Power

10Printer Description

Paper Specifications

12Printer Description

By 8.2

Supported Types of Paper

14Printer Description

Guidelines for Using Paper

16Printer Description

Paper Weight Equivalence Table

11. Paper Weight Equivalence

Labels

Transparencies

Vellum

Label Construction

Envelope Construction

Envelopes

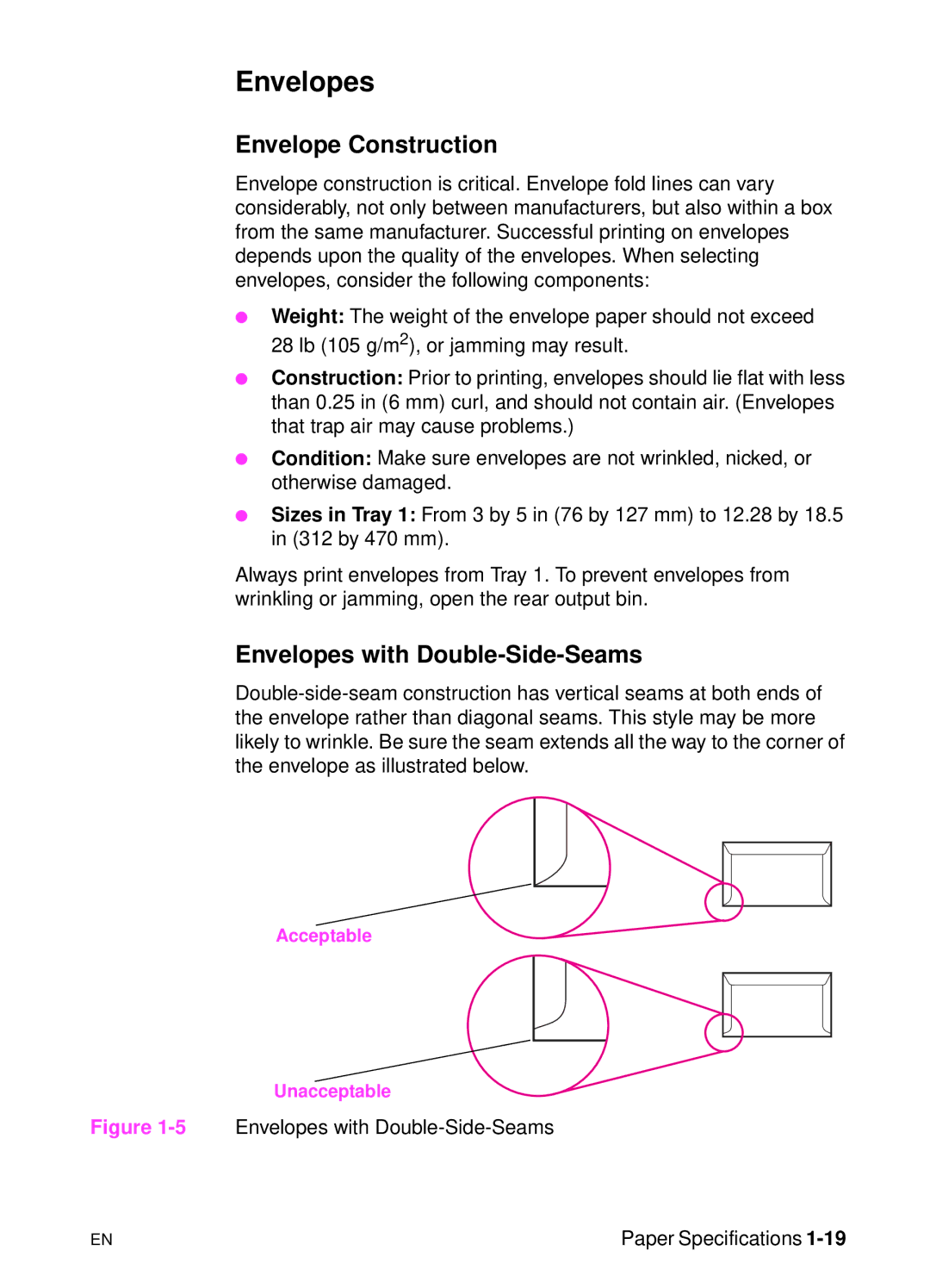

Envelopes with Double-Side-Seams

Card Stock and Heavy Paper

Envelopes with Adhesive Strips or Flaps

Envelope Margins

Envelope Storage

Card Stock Construction

Card Stock Guidelines

Safety Information

Laser Safety Statement

Canadian DOC Regulations

22Printer Description

FCC Regulations

Laser statement for Finland Luokan 1 laserlaite

Klass 1 Laser Apparat

Varoitus

Varning

Material Safety Data Sheet

Environmental Product Stewardship

Protecting the Environment

This HP LaserJet printer design reduces

Printer design eliminates

Service Approach

Service Approach

2Service Approach

Parts and Supplies

Ordering Information

Helpful Documentation

4Service Approach

Helpful Documentation Description or Use Part Number

Phone Numbers for Ordering

Exchange Program

Consumables

Technical Assistance

HP CompuServe Forum

6Service Approach

HP FIRST, Europe

North American Response Center Narc

Other Areas

8Service Approach

Toner Cartridge Information

Refilled Toner Cartridges

Recycling Toner Cartridges

Warranty Statement

10Service Approach

Printer Operation

Using the Control Panel

Control Panel Layout

Control Panel Lights

Control Panel Lights LightIndication

Control Panel Keys Function

Control Panel Keys

Paper Size

Settings and Defaults

Setting the Display Language

Settings and Defaults

Setting or Default Explanation

Control Panel Menus

To change a Control Panel setting

To print a Control Panel menu map

Print Menu MAP Print Configuration

Information Menu

Information Menu ItemExplanation

6Printer Operation

Paper Handling Menu

Paper Handling Menu ValuesExplanation

Tray 1 MODE= First Tray 1 SIZE= Letter Cassette

Tray 1 TYPE= Plain Tray 2 TYPE= Tray 3 TYPE=

Paper Handling Menu Values Explanation

8Printer Operation

Configure Fuser Mode no MENU=NOYES

Paper Handling Menu ItemValues

RESOLUTION=

Print Quality Menu

Print Quality Menu Values

Fastres

Dark

RET=MEDIUM OFF Light

ECONOMODE=OFF

Toner DENSITY=3 Create Cleaning

12Printer Operation

Printing Menu

Printing Menu Values Explanation

COPIES=1

PAPER= Letter

Printing Menu Values

14Printer Operation

PCL Font Internal

SOURCE=INTERNAL Soft

PCL Font

NUMBER=0

Append CR to LF=

16Printer Operation

Configuration Menu

Configuration Menu

Resource SAVE= OFF Auto

Configuration Menu Values Explanation

18Printer Operation

PROTECT= Auto

Clearablejob MEMORY, Press GO to Continue

Configuration Menu ItemValues

Auto CONTINUE=

Tonercontinue LOW=CONTINUE Stop

20Printer Operation

MODE=STANDARD Enhanced

Mopier Standard

RAM DISK=OFF

Configuration Menu Values

JAM RECOVERY=

RAM Disk

Auto OFF Paperoff REFORMING=OFF on

Maintenance OFF

MESSAGE=OFF

Small Paper

SPEED=NORMAL Slow

TIMEOUT=15

Menu

I/O Menu Values Explanation

BUFFER=AUTO Auto

I/O Menu ItemValues

Buffer SIZE=

Parallel High

SPEED=YES Parallel ADV FUNCTIONS=ON

26Printer Operation

EIO Menu Networked Printers

10. EIO Menu Values Explanation

CFG ETALK=NO

CFG TCP/IP=NO

28Printer Operation

11. Resets Menu Explanation

Resets Menu

Reset Memory

To enter Service Mode

Service Mode

30Printer Operation

Setting the Page Count, Maintenance Count

Service Menu

Serial Number

Count

32Printer Operation

Service Mode

Service Menu

12. Changing the Page Count Key Press Display

Description

Cold Reset Paper

Diagnostics

Maintenance Page Count

Clear Event Log

Testing the Printer

Engine Test

Resetting the Printer

Cold Reset

To perform a cold reset

Clearing Nvram

MS-DOS System Configuration

System Configuration

Parallel DOS Commands

Serial MS-DOS Commands

38Printer Operation

Serial Configuration

Printer I/O Configuration

Parallel Menu

Pacing Handshaking

40Printer Operation

Printer Maintenance

Cleaning the Printer and Accessories

2Printer Maintenance

Cleaning the Printer Component Cleaning Method / Notes

Inside General

Using the Printer Cleaning

Cleaning Spilled Toner

4Printer Maintenance

Preventative Maintenance

Reset Maintenance Count

Expected Life of Components

Life of Components Part name Quantity Expected Life

6Printer Maintenance

Functional Information

Printer Subsystems

2Functional Information

Power Supply System

AC/DC Power Distribution

4Functional Information

Overcurrent Overvoltage Protection

High Voltage Power Distribution

6Functional Information

Toner Cartridge Detection

DC Controller System

Laser and Scanner Drive

8Functional Information

Paper Motion Monitoring and Control

Solenoids, Sensors, Clutches, and Switches

Engine Test Print

Motors

10Functional Information

Page

Formatter System

PowerSave

12Functional Information

Resolution Enhancement technology REt

EconoMode

Input/Output

Printer Memory

Random Access Memory RAM

Read Only Memory ROM

Disk Accessory

Dimm Slots

Memory Enhancement technology MEt

Protect

PJL Overview

Control Panel

Image Formation System

18Functional Information

Page

Toner Cartridge

20Functional Information

Photosensitive Drum

8Photosensitive Drum Image Formation System

Cleaning the Drum

22Functional Information

Conditioning the Drum

10Primary Charging Roller Image Formation System

Bdic PCB

Writing the Image

24Functional Information

Developing the Image

Transferring the Image

26Functional Information

Image Fusing/Variable Fusing Temperature

Variable Fusing Temperature

28Functional Information

Paper Feed System

Paper Path

Clutches and Sensors

30Functional Information

Printing from Tray

32Functional Information

18Tray 2 Paper Path Paper Feed System

19Paper Skew Loop-forming

34Functional Information

Printing from the Optional 500-sheet and 250-sheet Trays

20250-sheet Paper Feeder Paper Feed System

21500-sheet Paper Feeder

36Functional Information

Paper Jam

Reversing/Refeed System

Duplexer

38Functional Information

22Paper Feed for the Duplexer Paper Feed System

Reversing System

40Functional Information

Duplexing Unit

Uncurling Function

Pause Mode

42Functional Information

25 Pause Mode

Dance Mode

Paper Jam in the Duplexer

44Functional Information

Basic Sequence of Operation

Printer Timing Period Purpose Remark

46Functional Information

Timing Diagram

48Functional Information

Removing and Replacing Parts

Memory Upgrade

User Installable Accessories

2Removing and Replacing Parts

Page

If an optional duplexer is installed

4Removing and Replacing Parts

Checking Memory Installation

Installing EIO Cards / Mass Storage

1Installing EIO Cards or Mass Storage Devices

6Removing and Replacing Parts

Removal and Replacement Strategy

Required Tools

8Removing and Replacing Parts

Screws Used in the Printer Drawing and Description Purpose

Screws Used in the Printer Drawing and Description Purpose

Removing Covers

10Removing and Replacing Parts

Rear Door / Rear Output Bin

Support Strap

12Removing and Replacing Parts

Top Cover

Top screws Toner Cartridge Drive Arm Rear screws

14Removing and Replacing Parts

Control Panel Overlay and Control Panel

16Removing and Replacing Parts

Toner Cartridge Door Assembly

9Toner Cartridge Door Assembly Under Side of Top Cover Door

18Removing and Replacing Parts

Front Cover and Tray

Tray

Front Cover Pins

20Removing and Replacing Parts

Face Down Assembly

13Location of Face Down Assembly Base

14Face Down Assembly

22Removing and Replacing Parts

Left and Right Side Covers

24Removing and Replacing Parts

Tray 1 Inner Cover

17Tray 1 Inner Cover front of printer

26Removing and Replacing Parts

Right and Left Corner Covers

Removing Assemblies

Transfer Roller Assembly

28Removing and Replacing Parts

21Right Side of Transfer Roller

30Removing and Replacing Parts

Fuser

Paper Handling PCA

Top Margin Adjustment

32Removing and Replacing Parts

25Location of VR401 Removing Assemblies

Main Gear Assembly

34Removing and Replacing Parts

27Removing the Main Gear Assembly

Pickup Gear Assembly

36Removing and Replacing Parts

Tray 2 Shaft Gear to the Paper Feed Roller Assembly Gear

38Removing and Replacing Parts

Tray 1 Pickup Solenoid

Fan

30Fan right side view of printer

Formatter Assembly

40Removing and Replacing Parts

Tray 1 Roller

42Removing and Replacing Parts

Tray 2 Roller

Paper Feed Roller Assembly

34Paper Feed Roller Clutch left side view of printer

44Removing and Replacing Parts

35Location of two common screws inside printer

36Paper Feed Roller Assembly bottom view of printer

DC Controller Board and Power Supply

46Removing and Replacing Parts

37DC Controller Assembly rear view of printer

38DC Controller Assembly long screws

48Removing and Replacing Parts

39DC Controller Assembly

Paper Feed Belt Assembly

50Removing and Replacing Parts

41Paper Feed Belt Assembly removed

52Removing and Replacing Parts

Tray 1 Shaft

Must be installed on top of it

54Removing and Replacing Parts

Tray 2 Shaft

Reassembly Steps

44Reassembly of Tray 2 Shaft

56Removing and Replacing Parts

Tray 1 Lift Plate

Tray 1 Separation Pad

46Tray 1 Separation Pad Removing Assemblies

58Removing and Replacing Parts

Paper Guide

Paper Path Detect Sensor

48Paper Path Detect Sensor

60Removing and Replacing Parts

Face Down Bin Full Sensor

50Detail of Bin Full Sensor

Power Connection

62Removing and Replacing Parts

Registration Assembly

52Registration Assembly

53Registration Assembly Clutch

64Removing and Replacing Parts

Upper Delivery Assembly

54Upper Delivery Assembly rear left view of printer

66Removing and Replacing Parts

Delivery Roller Removal

56Delivery Roller Components

68Removing and Replacing Parts

Laser Scanner Assembly

58Laser Scanner Assembly top inside view of printer

70Removing and Replacing Parts

Main Motor

Toner Cartridge Guides

Power Inlet Assembly

72Removing and Replacing Parts

Optional 500-sheet Tray Disassembly

62Optional 500-sheet Tray top view

74Removing and Replacing Parts

63500-sheet Tray top view with covers removed

Tray Indicator Assembly

64Removing the Tray Indicator Assembly

Left Front Corner Cover Installation

76Removing and Replacing Parts

Paper Size Spring Assembly

66Removing the Paper Size Spring Assembly

78Removing and Replacing Parts

Roller and Feed Roller

Feed Roller Removal

Roller Removal

Gear Assembly and PCA

68Removing the Gear Assembly and PCA

Power Connector

80Removing and Replacing Parts

Separation Roller

70Removing the Separation Roller

82Removing and Replacing Parts

Troubleshooting

Major Steps for Troubleshooting

Troubleshooting Process

2Troubleshooting

Image Quality

Troubleshooting Process Flow

4Troubleshooting

Troubleshooting Process

6Troubleshooting

Troubleshooting the Printing System

Preliminary Operating Checks

Power On

Power on Defect or Blank Display ProblemAction

8Troubleshooting

No AC Power Cause

Action

No DC Power Cause Action

Engine Test Button Location

10Troubleshooting

Printing an Engine Test

Display

12Troubleshooting

Event Log

Event Log

14Troubleshooting

Display the Event Log

Print the Event Log

Interpret the Event Log

Left-most column

16Troubleshooting

Printer Messages

Alphabetical Printer Messages Control Panel Message

Event Log Explanation Recommended Message Action

Cannot Duplex Rear BIN Open Check Input Device

Disk Device Failure

18Troubleshooting

Disk is Write Protected Flash Device Failure

Flash is Write Protected Initializing

Input Device Condition xx.yy

20Troubleshooting

Do not Power OFF

Loading

Memory Full Stored Data Lost

Offline

22Troubleshooting

RAM Disk Device Failure

RAM Disk File

System is Full

Tray x Empty

24Troubleshooting

Unsupported Size in Tray YY

USE Type Size INSTEAD?

Wait for Printer to Reinitialize

26Troubleshooting

Numerical Printer Messages Control Panel Message

Event Explanation Recommended Log Action Message

Paper JAM

13.10 or Paper delay jam at paper

28Troubleshooting

For 13.20

Buffer Overflow

Press GO to Continue Parallel I/O Buffer Overflow

Press GO to Continue Serial I/O Buffer Overflow

Press GO to Continue

30Troubleshooting

Printer Error

Recommended Action

Fuser Error

32Troubleshooting

Printer Error

34Troubleshooting

Cycle Power to Continue

36Troubleshooting

69.x

38Troubleshooting

8x.yyyy

General Paper Path Troubleshooting Questions ProblemAction

General Paper Path Troubleshooting

40Troubleshooting

General Paper Path Troubleshooting Questions Problem Action

42Troubleshooting

Paper Path Test

Information Pages

Menu Map

44Troubleshooting

Configuration

5Configuration

46Troubleshooting

Verify installed options

48Troubleshooting

Image Quality

Check the Toner Cartridge

Image Quality Checks Image Quality Checks Action

EconoMode

50Troubleshooting

Image Defects

Black Lines perpendicular path Possible Cause Action

10. Black Possible Cause Action

52Troubleshooting

10. Black

11. Blank Possible Cause Action

Empty weight = 1450 grams 51.5 oz

54Troubleshooting

11. Blank

12. Blank Spots

12. Blank Spots Possible Cause Action

56Troubleshooting

13. Character Voids Possible Cause Action

14. Creases Possible Cause Action

58Troubleshooting

15. Curl Possible Cause Action

16. Dirt on Back Possible Cause Action

17. Distorted Image

60Troubleshooting

18. Dropouts

Family Paper Specifications Guide

19. Faded Print/Bubbles Possible Cause Action

62Troubleshooting

19. Faded Print/Bubbles

20. Gray Background Possible Cause Action

64Troubleshooting

21. Horizontal Smudges Possible Cause Action

22. Horizontal White Lines

23. Light Print, Dark Print, or Fade Possible Cause Action

23. Light Print, Dark Print, or Fade

66Troubleshooting

24. Loose Toner Possible Cause Action

Examine and clean rollers in the paper path

25. Repetitive Defects Possible Cause Action

26. Skew Possible Cause Action

68Troubleshooting

27. Toner Smear Possible Cause Action

28. Toner Specks Possible Cause Action

Dirt in printer

Paper SPEED=SLOW

70Troubleshooting

29. Vertical Black Lines

30. Vertical Dots

31. Vertical White Lines

72Troubleshooting

Repetitive Defect Ruler

6Repetitive Defect Ruler Troubleshooting the Printing System

Image System Troubleshooting Half Self-Test Functional Check

74Troubleshooting

Drum Rotation Functional Check

Interface Troubleshooting

EIO Troubleshooting

76Troubleshooting

Communications Check

7JetDirect Configuration Troubleshooting the Printing System

JetDirect Configuration

78Troubleshooting

Reference Diagrams

Locations of Components

80Troubleshooting

9250-sheet Paper Feeder

10250-sheet Paper Feeder Reference Diagrams

82Troubleshooting

11Tray 2 Paper Path

12500-sheet Paper Feeder Reference Diagrams

84Troubleshooting

13500-sheet Paper Feeder

Duplexing Unit

86Troubleshooting

Duplexing Unit

Sensors and Signals

88Troubleshooting

Page

32. Sensors and Signals Name

90Troubleshooting

TSW1

19Location of Sensors and Switches

92Troubleshooting

20Duplexer Sensors and Switches Reference Diagrams

94Troubleshooting

22Motors Duplexing unit Reference Diagrams

96Troubleshooting

Page

98Troubleshooting

26PCA Duplexing Unit Reference Diagrams

100Troubleshooting

27Clutches and Solenoids

28Clutches and Solenoids Duplexing Unit Reference Diagrams

102Troubleshooting

30Switches 500-sheet Paper Feeder Reference Diagrams

31DC Controller Board Test Points and Switches

104Troubleshooting

32250-sheet Paper Feeder Sensors Reference Diagrams

106Troubleshooting

33DC Controller PCA I/O 1 Reference Diagrams

DC Controller PCA Inputs and Outputs

108Troubleshooting

34DC Controller PCA I/O 2

35DC Controller PCA I/O 3 Reference Diagrams

110Troubleshooting

36DC Controller PCA I/O 4

Parts and Diagrams

How To Use the Parts Lists and Diagrams

2Parts and Diagrams

Ordering Parts

Ordering Consumables

Numbers

Accessories and Supplies Description Exchange No Product No

Accessories and Supplies

4Parts and Diagrams

Accessories and Supplies Description Exchange No. Product No

Common Hardware and Replacement Cables

6Parts and Diagrams

Screws Used in the Printer Description

Replaceable Cables Description

Illustrations and Parts Lists

1Assembly Location Diagram

8Parts and Diagrams

Illustrations and Parts Lists

10Parts and Diagrams

2External Covers and Panels

Illustrations and Parts Lists

Top Cover Assembly Item No Quantity Description

12Parts and Diagrams

Top Cover Assembly Item No Quantity Description

14Parts and Diagrams

Internal Components 1 Item No. Part No Quantity Description

Internal Components 1 Item No. Part No Quantity Description

16Parts and Diagrams

5Internal Components 2

Internal Components 2 Item No. Part No Quantity Description

18Parts and Diagrams

6Internal Components 3

Internal Components 3 Item No. Part No Quantity Description

20Parts and Diagrams

7Internal Components 4

Illustrations and Parts Lists

8Upper Delivery Assembly

22Parts and Diagrams

9Tray 2 Paper Pickup Roller Assembly

10Paper Feed Belt Assembly

24Parts and Diagrams

Illustrations and Parts Lists

11Paper Feed Assembly

26Parts and Diagrams

Illustrations and Parts Lists

12Registration Roller Assembly

28Parts and Diagrams

RG5-3524-000CN Registration Roller Assembly

30Parts and Diagrams

Sheet Tray

16 -sheet Tray Item No. Part No Quantity Description

14Main Drive Assembly

32Parts and Diagrams

Illustrations and Parts Lists

15Pickup Drive Assembly

34Parts and Diagrams

16PCA Assembly Locations

17Printer Controller Assembly

36Parts and Diagrams

Fuser

21. Fuser Item No. Part No Quantity Description

38Parts and Diagrams

19500-sheet Feeder

22 -sheet Feeder Item No. Part No Quantity Description

40Parts and Diagrams

20500-sheet Feeder

23 -sheet Feeder Item No. Part No Quantity Description

42Parts and Diagrams

Alphabetical Parts List

Description Part Number Table Number

Description Part Number Table Number

44Parts and Diagrams

70 on

46Parts and Diagrams

Numerical Parts List

Part Number Description Table Number

48Parts and Diagrams

110V RH2-5337-000CN 220V RG5-3517-000CN DC Controller 19 on

50Parts and Diagrams

Part Number Description Table Number

52Parts and Diagrams

Index

Index

Index

Index