2.4 Special Paper

2.4Special Paper

Besides plain paper, this printer can use the following types of special paper:

Paper type to be used | Media type to be selected | |||

Thin paper (60 to 64 g/m²) | Vellum | |||

|

| |||

Thick paper (105 to 220 g/m²) | Thick | |||

| ||||

Overhead projector transparencies Transparency | ||||

|

|

| ||

Postcards |

| Cardstock | ||

|

|

| ||

Envelopes |

| Envelope | ||

|

|

| ||

Labels |

| Labels | ||

|

| |||

Recycled paper | Recycle | |||

|

| |||

Colored paper | Color | |||

|

| |||

Preprinted paper | Preprint | |||

|

|

| ||

Table |

|

| ||

|

|

| When printing on A4 size paper with thickness | |

|

|

| ||

|

|

| above 200g/m2, feed the paper sideways from | |

| Note | the MP tray. Landscape feeding can cause | ||

|

|

| paper jams. |

|

Before purchasing any special paper, make a test print using the printer and check whether the results are satisfactory.

To avoid problems, stack transparencies, labels, or envelopes on the tray or cassette face up.

Major considerations for each type of special paper are given below.

Transparency

Transparencies for overhead projectors must withstand the heat of fusing during the printing process. The recommended transparency product is as follows:

3M CG3700 (Letter, A4)

To avoid problems, always feed OHP transparencies from the

When unloading transparencies (e.g., for clearing jams), hold them carefully by the edges to avoid leaving fingerprints on them.

You can assign one of these special paper type to a paper cassette or MP

Note that some types of special paper do not allow feeding from the paper feeder cassette or duplex

2.4.1Selecting the special paper

Since special paper differs significantly in paper composition and quality, special paper is more likely to cause problems than white bond paper during printing. When using special paper, be sure that they are manufactured for photocopiers and/or printers.

| Kyocera Mita shall not be liable for any danger |

| to a person or machine that is caused by using |

Note | special paper (e.g., fumes emitted from the |

| special paper). |

Adhesive-backed labels

Label paper must be fed manually.

For printing on labels, use extreme care so that the adhesive may not come in direct contact with any part of the printer. Adhesives that stick to the drum or rollers will cause printer damage.

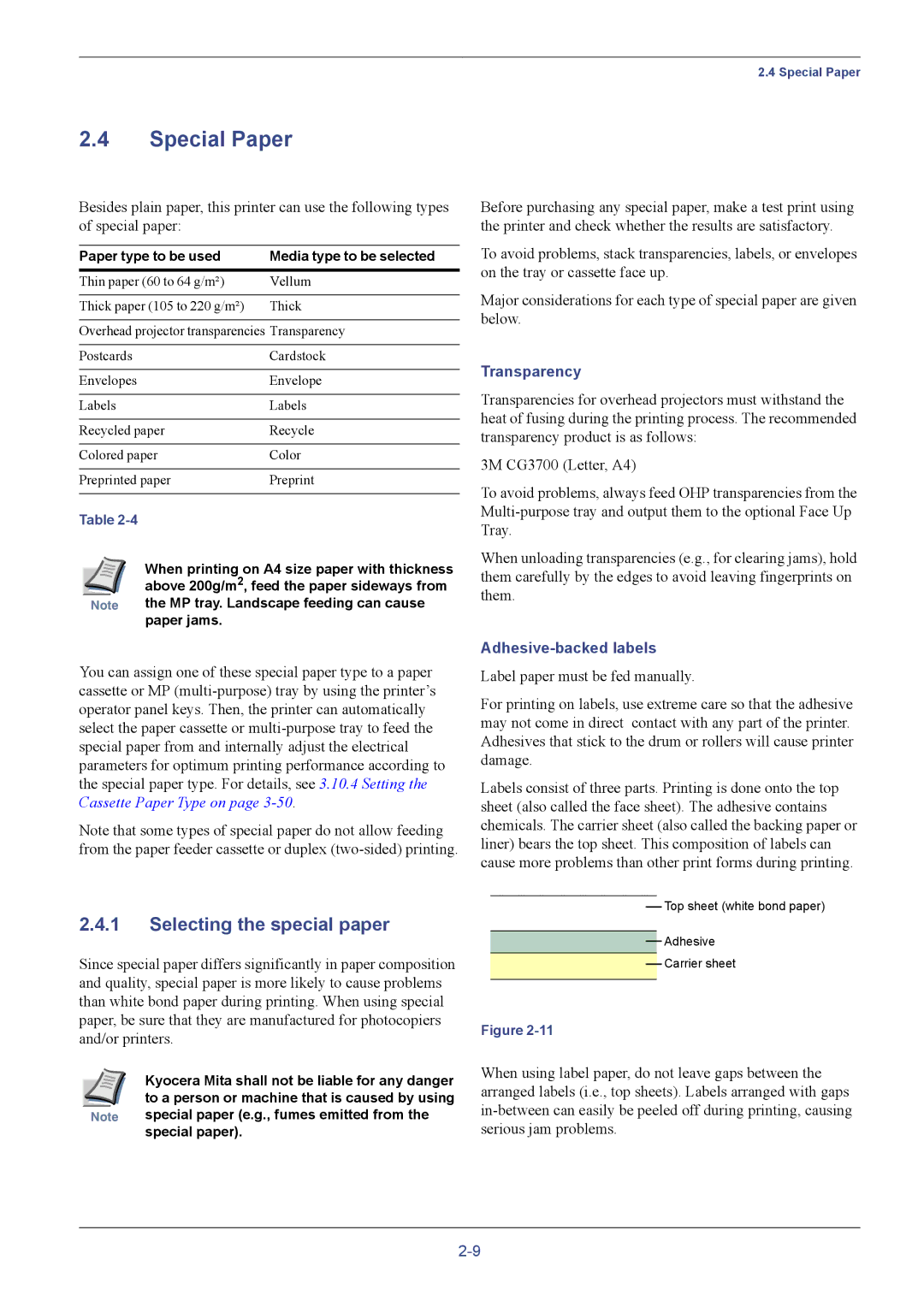

Labels consist of three parts. Printing is done onto the top sheet (also called the face sheet). The adhesive contains chemicals. The carrier sheet (also called the backing paper or liner) bears the top sheet. This composition of labels can cause more problems than other print forms during printing.

Top sheet (white bond paper)

![]() Adhesive

Adhesive

Carrier sheet

Figure

When using label paper, do not leave gaps between the arranged labels (i.e., top sheets). Labels arranged with gaps