17 Canned Cycles for Drilling

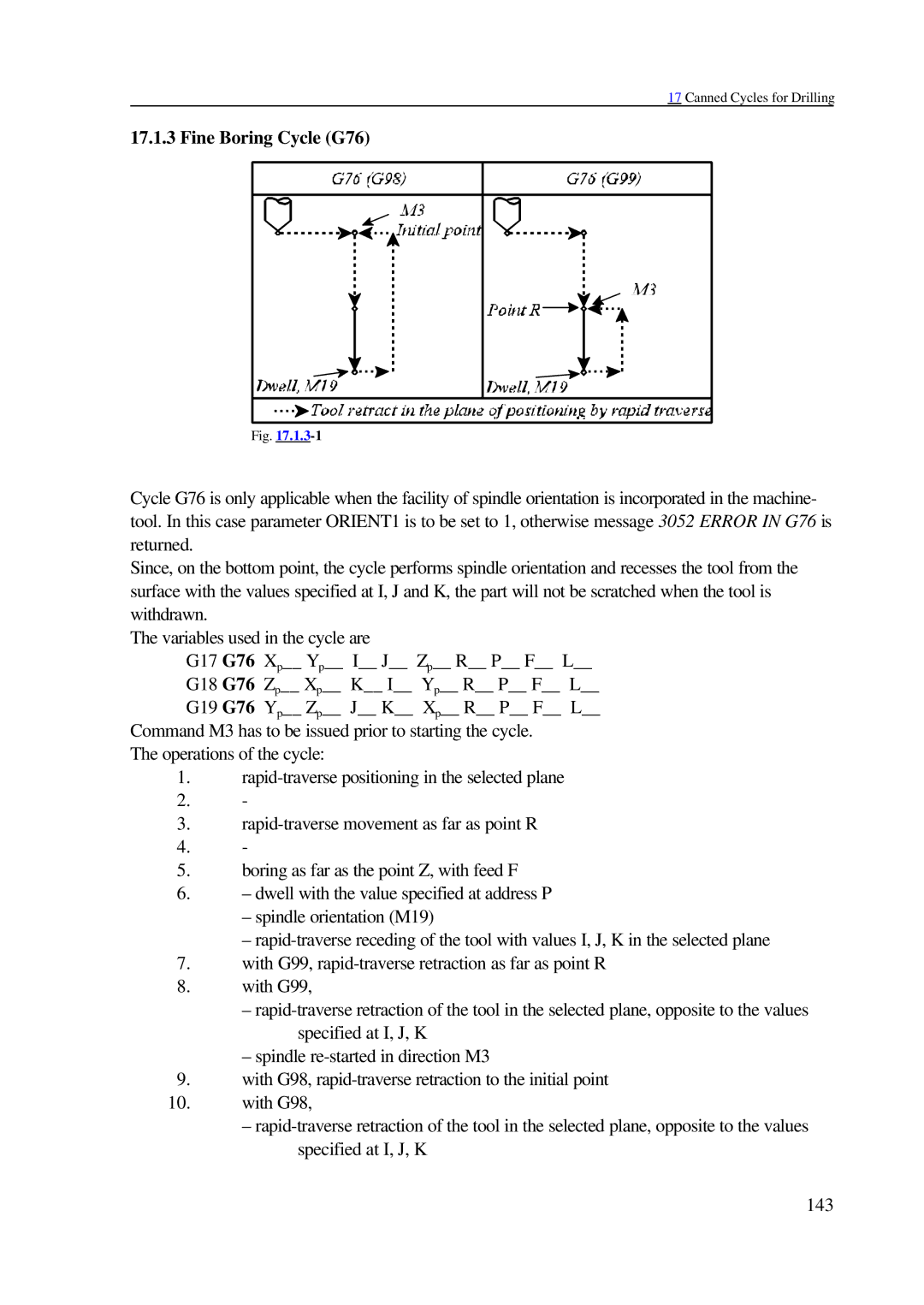

17.1.3 Fine Boring Cycle (G76)

Fig.

Cycle G76 is only applicable when the facility of spindle orientation is incorporated in the machine- tool. In this case parameter ORIENT1 is to be set to 1, otherwise message 3052 ERROR IN G76 is returned.

Since, on the bottom point, the cycle performs spindle orientation and recesses the tool from the surface with the values specified at I, J and K, the part will not be scratched when the tool is withdrawn.

The variables used in the cycle are

G17 G76 Xp__ Yp__ I__ J__ Zp__ R__ P__ F__ L__

G18 G76 Zp__ Xp__ K__ I__ Yp__ R__ P__ F__ L__

G19 G76 Yp__ Zp__ J__ K__ Xp__ R__ P__ F__ L__ Command M3 has to be issued prior to starting the cycle.

The operations of the cycle:

1.

2.-

3.

4.-

5.boring as far as the point Z, with feed F

6.– dwell with the value specified at address P

–spindle orientation (M19)

–

7.with G99,

8.with G99,

–

–spindle

9.with G98,

10.with G98,

–

143