14 The Tool Compensation

14.5 Cutter Compensation (G38, G39, G40, G41, G42)

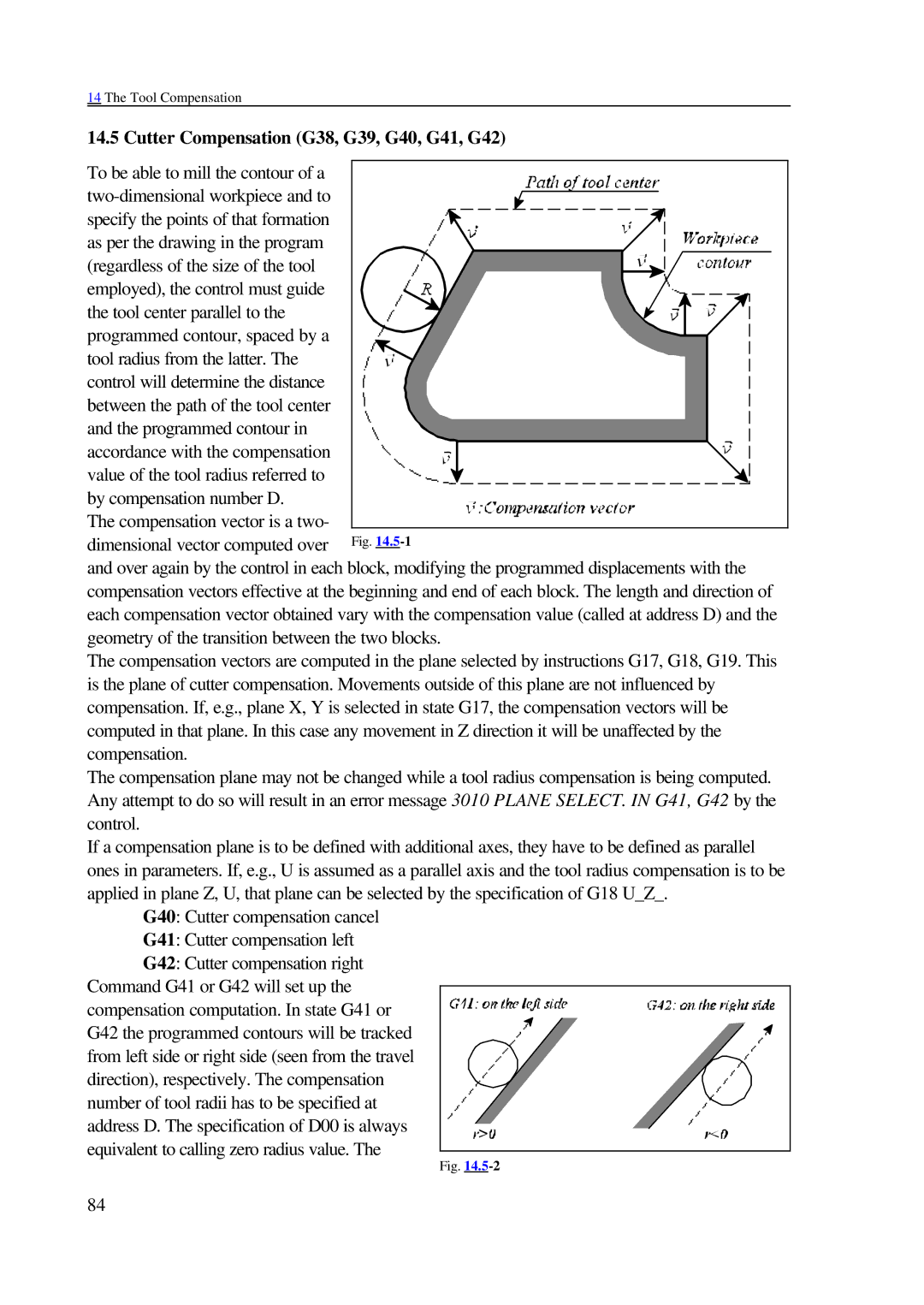

To be able to mill the contour of a

specify the points of that formation

as per the drawing in the program (regardless of the size of the tool employed), the control must guide the tool center parallel to the programmed contour, spaced by a tool radius from the latter. The

control will determine the distance between the path of the tool center and the programmed contour in

accordance with the compensation value of the tool radius referred to by compensation number D.

The compensation vector is a two- dimensional vector computed over

and over again by the control in each block, modifying the programmed displacements with the compensation vectors effective at the beginning and end of each block. The length and direction of each compensation vector obtained vary with the compensation value (called at address D) and the geometry of the transition between the two blocks.

The compensation vectors are computed in the plane selected by instructions G17, G18, G19. This is the plane of cutter compensation. Movements outside of this plane are not influenced by compensation. If, e.g., plane X, Y is selected in state G17, the compensation vectors will be computed in that plane. In this case any movement in Z direction it will be unaffected by the compensation.

The compensation plane may not be changed while a tool radius compensation is being computed. Any attempt to do so will result in an error message 3010 PLANE SELECT. IN G41, G42 by the control.

If a compensation plane is to be defined with additional axes, they have to be defined as parallel ones in parameters. If, e.g., U is assumed as a parallel axis and the tool radius compensation is to be applied in plane Z, U, that plane can be selected by the specification of G18 U_Z_.

G40: Cutter compensation cancel

G41: Cutter compensation left

G42: Cutter compensation right Command G41 or G42 will set up the

compensation computation. In state G41 or G42 the programmed contours will be tracked from left side or right side (seen from the travel direction), respectively. The compensation number of tool radii has to be specified at address D. The specification of D00 is always

equivalent to calling zero radius value. The

Fig.

84