NCT 99M NCT 2000M

Manufactured by NCT Automation kft

Contents

Dwell G04

100

Page

180

Page

Part Program

Introduction

O1234PROGRAM NAMEs/1N12345G1X0Y...sG2Z5...s....s N1G40...M2s

Block

Fundamental Terms

Introduction

G90 X50 Y80 Z40

M3 M8

Introduction

Unit and Increment System of Axes

Controlled Axes

Names of axes

IS-A

Preparatory Functions G codes

116

141

G01 v F

Interpolation

Positioning G00

Linear Interpolation G01

G01 X100 Y80 F150

Circular and Spiral Interpolation G02, G03

Case

G03 X0 Y100

Helical Interpolation G02, G03

G17 G03 X0 Y100 Z20 R100 F150

Equal Lead Thread Cutting G33

An example of programming a thread-cutting

G13.1

Polar Coordinate Interpolation G12.1, G13.1

G12.1

Polar Coordinate Interpolation G12.1, G13.1

O7500POLAR Coordinate Interpolation

Direction X on rotary axis C

Cylindrical Interpolation G7.1

28.65mm⋅ 180 ⋅ π = 0.5mm

Cylindrical Interpolation G7.1

Absolute and Incremental Programming G90, G91, Operator

Polar Coordinates Data Command G15, G16

Coordinate Data

G90 G16 G01 X100 Y60 F180

Inch/Metric Conversion G20, G21

Specification and Value Range of Coordinate Data

Rotary Axis Roll-over

ROLLOVENC=1

Rollovenc =1

Cutting Feed Rate

Feed

Feed in rapid travers

Feed per Minute G94 and Feed per Revolution G95

Clamping the Cutting Feed

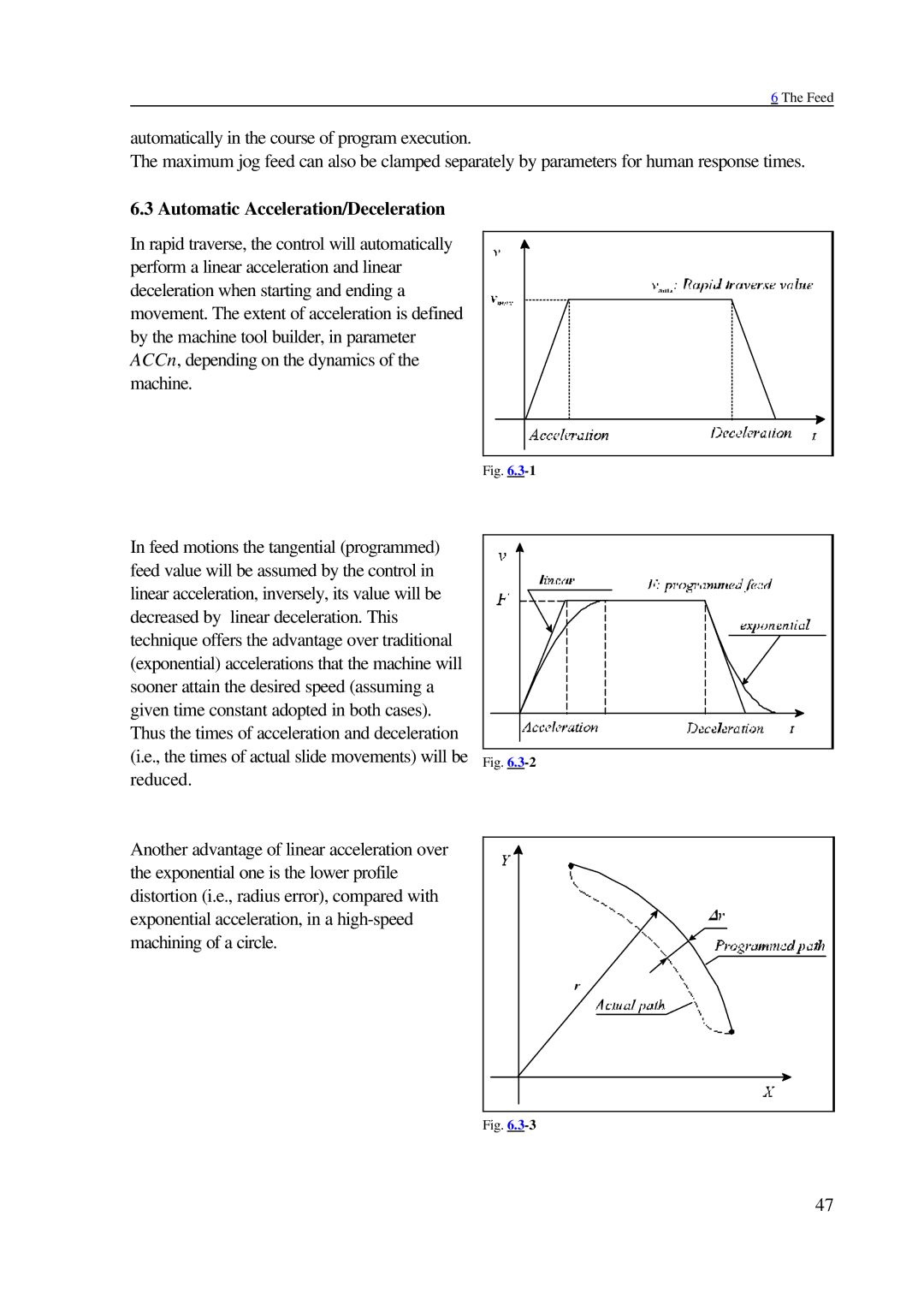

Automatic Acceleration/Deceleration

Exact Stop G09

Exact Stop Mode G61

Feed Control Functions

Automatic Corner Override G62

Continuous Cutting Mode G64

Override and Stop Inhibit Tapping Mode G63

Internal Circular Cutting Override

Dwell G04

Automatic Reference Point Return G28

Reference Point

Automatic Return from the Reference Point G29

Automatic return to reference points 2nd, 3rd, 4th G30

G90 G30 P1 X500 Y200 G29 X700 Y150

Machine Coordinate System

Coordinate Systems, Plane Selection

Work Coordinate Systems

Setting the Machine Coordinate system

Setting the Work Coordinate Systems

Positioning in the Machine Coordinate System G53

Selecting the Work Coordinate System

Creating a New Work Coordinate System G92

Programmed Setting of the Work Zero Point Offset

Local Coordinate System

G90 G52 X60 Y40

Plane Selection G17, G18, G19

Codes

Programming of Constant Surface Speed Control

Spindle Speed Command code S

Spindle Function

Constant Surface Speed Clamp G92

10.2.1Constant Surface Speed Control Command G96, G97

G96 S

Oriented Spindle Stop

Selecting an Axis for Constant Surface Speed Control

G96 P. Interpretation of address P

Spindle Position Feedback

G25

Spindle Positioning Indexing

Spindle Speed Fluctuation Detection G25, G26

G26

Spindle Function

Spindle Function

Program Format for Tool Number Programming

Tool Select Command Code T

Tool Function

Tool Function

Miscellaneous Functions Codes M

Miscellaneous and Auxiliary Functions

Sequence of Execution of Various Functions

Auxiliary Function Codes A, B, C

Part Program Configuration

M99

M98 P.... L

Return from a Sub-program

M99 P

Jump within the Main Program

Referring to Tool Compensation Values H and D

Tool Compensation

Limit values of geometry and wear

G44 compensation

Tool Length Compensation G43, G44, G49

G43 q H or G44 q H

G43 + compensation

Tool Offset G45...G48

Tool Compensation

Tool Compensation

Tool Compensation

Cutter Compensation G38, G39, G40, G41, G42

G41

Tool Compensation

Start up of Cutter Compensation

Tool Compensation

G91 G17 G40 N110 G42 G1 X-80 Y60 I50 J70 D1 N120

N10 G40 G17 G0 X0 Y0 N15 G91 G42 D1 N20 G1 N25 X30 Y60

Rules of Cutter Compensation in Offset Mode

Tool Compensation

G91 G17 G42 N110 G1 X40 Y50 N120 N130 N140 X50 Y-20

Canceling of Offset Mode

G91 G17 G42 N100 G1 X50 Y60 N110 G40 X70 Y-60 I100 J-20

G42 G17 G91 N110 G1 X80 Y40 N120 G40 N130 X-70 Y20

Change of Offset Direction While in the Offset Mode

Tool Compensation

Programming Corner Arcs G39

Programming Vector Hold G38

14.5.6

When two interpolations outside of the selected plane

G17 G91 N110 G41 G0 X50 Y70 D1 N120 G1 Z-40 N130 Y40

103

Tool Compensation

Tool Compensation

Tool Compensation

Interferences in Cutter Compensation

Tool Compensation

Tool Compensation

Tool Compensation

Programming the Three-dimensional Tool Offset G40, G41, G42

Three-dimensional Tool Offset G41, G42

G40 or D00

Three-dimensional Offset Vector

Tool Compensation

Coordinate System Rotation G68, G69

Special Transformations

G51 v P

Scaling G50, G51

G51.1

Programmable Mirror Image G50.1, G51.1

Rotation-scaling Scaling-rotation

Rules of Programming Special Transformations

Special Transformations

Programming Chamfer and Corner Round

Automatic Geometric Calculations

Specifying Straight Line with Angle

Is equivalent to the block below

Intersection Calculations in the Selected Plane

Linear-linear Intersection

Automatic Geometric Calculations

Automatic Geometric Calculations

Linear-circular Intersection

127

Let us see the following example

Circular-linear Intersection

Let us see an example

Circular-circular Intersection

132

Let us see the following example

Chaining of Intersection Calculations

Canned Cycles for Drilling

136

Position of hole Xp, Yp, Zp

Displacement after spindle Orientation I, J, K

Code of drilling

Initial point

Data of drilling

Examples of modal drilling codes and cycle variables

Examples of using cycle repetitions

Canned Cycles for Drilling

Counter Tapping Cycle G74

Fine Boring Cycle G76

Drilling, Spot Boring Cycle G81

Canned Cycle Cancel G80

Drilling, Counter Boring Cycle G82

Peck Drilling Cycle G83

Tapping Cycle G84

With G98, rapid-traverse retraction to the initial point

= distance between point R and point Z

Canned Cycles for Drilling

Boring Cycle G85

Boring Cycle Tool Retraction with Rapid Traverse G86

Boring Cycle, Manual Operation at Bottom Point

Boring Cycle/Back Boring Cycle G87

Back Boring Cycle

Boring Cycle Manual Operation on the Bottom Point G88

Canned Cycles for Drilling

Canned Cycles for Drilling

Skip Function G31

Measurement Functions

Automatic Tool Length Measurement G37

Measurement Functions

G23

Safety Functions

Programmable Stroke Check G22, G23

Parametric Overtravel Positions

Stroke Check Before Movement

C I1 J1 K1 I2 J2 K2 ... I10 J10 K10

Custom Macro

Simple Macro Call G65

G67

Particular number. For example

Illegal G Code

Macro Modal Call From Each Block G66.1

Custom Macro Call Using G Code

Subprogram Call with M Code

Custom Macro Call Using M Code

#198=s

Subprogram Call with T Code

#199=t

Subprogram Call with S Code

Multiple Calls

Level of call

Referring to a variable

Format of Custom Macro Body

Variables of the Programming Language

Identification of a Variable

Numerical Format of Variables

Vacant Variables

Common Variables #100 through #199, #500 through #599

Types of Variables

Local Variables #1 through #33

System Variables

Interface input signals #1000-#1015, #1032

Interface output signals #1100-#1115, #1132

Tool compensation values #10001 through #13999

Work zero-point offsets #5201 through #5328

Suppression of block-by-block execution #3003

Alarm #3000

Millisecond timer #3001

Main time timer #3002

Mirror image status #3007

Suppression of stop button, feed override, exact stop #3004

Stop with message #3006

Modal information #4001 through #4130, #4201 through #4330

Instantaneous positions in the work coordinate system

Tool-length compensation

Skip signal position

Definition, Substitution #i = #j

Servo lag

Instructions of the Programming Language

Logical sum, or #i = #j or #k

Arithmetic Operations and Functions

Single-operand minus #i = #j The code of the operation is

Subtraction #i = #j #k

Arc cosine #i = Acos #j

Square root #i = Sqrt #j

Absolute value #i = ABS #j

Arc tangent #i = Atan #j

Logarithm natural #i = LN #j

Unconditional Divergence GOTOn

Logical Operations

Conditional Instruction IFconditional expression then

Conditional Divergence IFconditional expression GOTOn

Instructions DOm and ENDm must be put in pairs

Pairs DOm ... ENDm may not be overlapped

Decimal data print output

Data Output Commands

Periphery open

Binary data print output

Decimal data output Dprnt

Characters to be output are

194

NC and Macro Instructions

Closing a peripheral PCLOSn

Execution of NC and Macro Instructions in Time

Sbstm =0

Displaying Macros and Sub-programs in Automatic Mode

Pocket-milling Macro Cycle

Degenerated cases of cavity milling

Error messages in the course of pocket milling

Custom Macro

202

15 , 72

Index in Alphabetical Order

Index in Alphabetical Order

Index in Alphabetical Order

Index in Alphabetical Order