4 The Interpolation

– The specified

4.5 Equal Lead Thread Cutting (G33)

The instruction G33 v F Q G33 v E Q

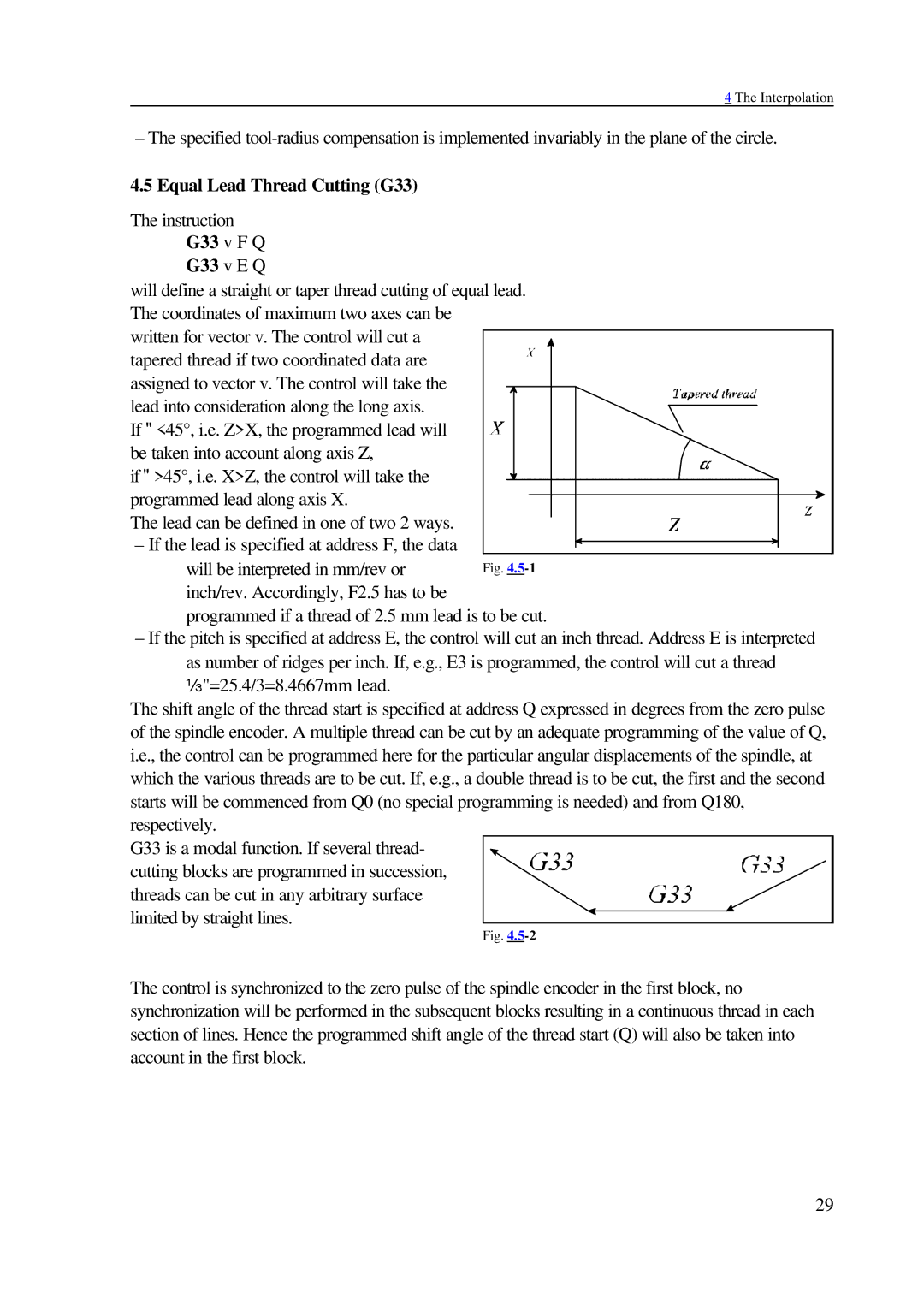

will define a straight or taper thread cutting of equal lead. The coordinates of maximum two axes can be

written for vector v. The control will cut a

tapered thread if two coordinated data are assigned to vector v. The control will take the

lead into consideration along the long axis.

If "<45°, i.e. Z>X, the programmed lead will be taken into account along axis Z,

if ">45°, i.e. X>Z, the control will take the

programmed lead along axis X. The lead can be defined in one of two 2 ways.

– If the lead is specified at address F, the data will be interpreted in mm/rev or

inch/rev. Accordingly, F2.5 has to be

programmed if a thread of 2.5 mm lead is to be cut.

– If the pitch is specified at address E, the control will cut an inch thread. Address E is interpreted as number of ridges per inch. If, e.g., E3 is programmed, the control will cut a thread a"=25.4/3=8.4667mm lead.

The shift angle of the thread start is specified at address Q expressed in degrees from the zero pulse of the spindle encoder. A multiple thread can be cut by an adequate programming of the value of Q, i.e., the control can be programmed here for the particular angular displacements of the spindle, at which the various threads are to be cut. If, e.g., a double thread is to be cut, the first and the second starts will be commenced from Q0 (no special programming is needed) and from Q180, respectively.

G33 is a modal function. If several thread-

cutting blocks are programmed in succession, threads can be cut in any arbitrary surface

limited by straight lines.

Fig.

The control is synchronized to the zero pulse of the spindle encoder in the first block, no synchronization will be performed in the subsequent blocks resulting in a continuous thread in each section of lines. Hence the programmed shift angle of the thread start (Q) will also be taken into account in the first block.

29