17 Canned Cycles for Drilling

– In state G94 (feed per minute),

where P is the thread pitch in mm/rev or inches/rev, S is the spindle speed in rpm

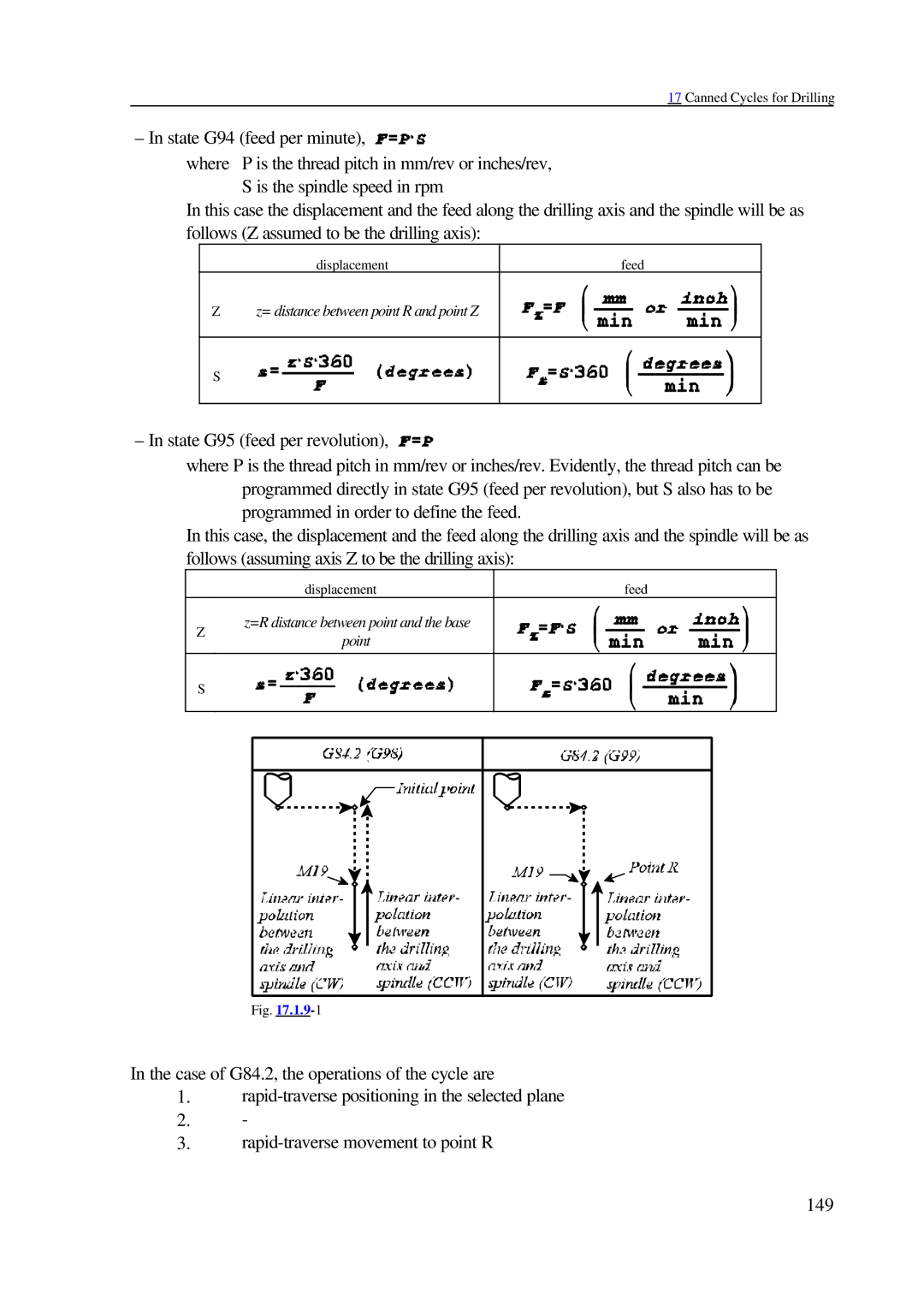

In this case the displacement and the feed along the drilling axis and the spindle will be as follows (Z assumed to be the drilling axis):

displacement

feed

Z z= distance between point R and point Z

S

– In state G95 (feed per revolution),

where P is the thread pitch in mm/rev or inches/rev. Evidently, the thread pitch can be programmed directly in state G95 (feed per revolution), but S also has to be programmed in order to define the feed.

In this case, the displacement and the feed along the drilling axis and the spindle will be as follows (assuming axis Z to be the drilling axis):

displacement | feed |

z=R distance between point and the base

Z

point

S

Fig.

In the case of G84.2, the operations of the cycle are

1.

2.-

3.

149