17 Canned Cycles for Drilling

Distance E will be taken from the program (address E) or from parameter CLEG83.

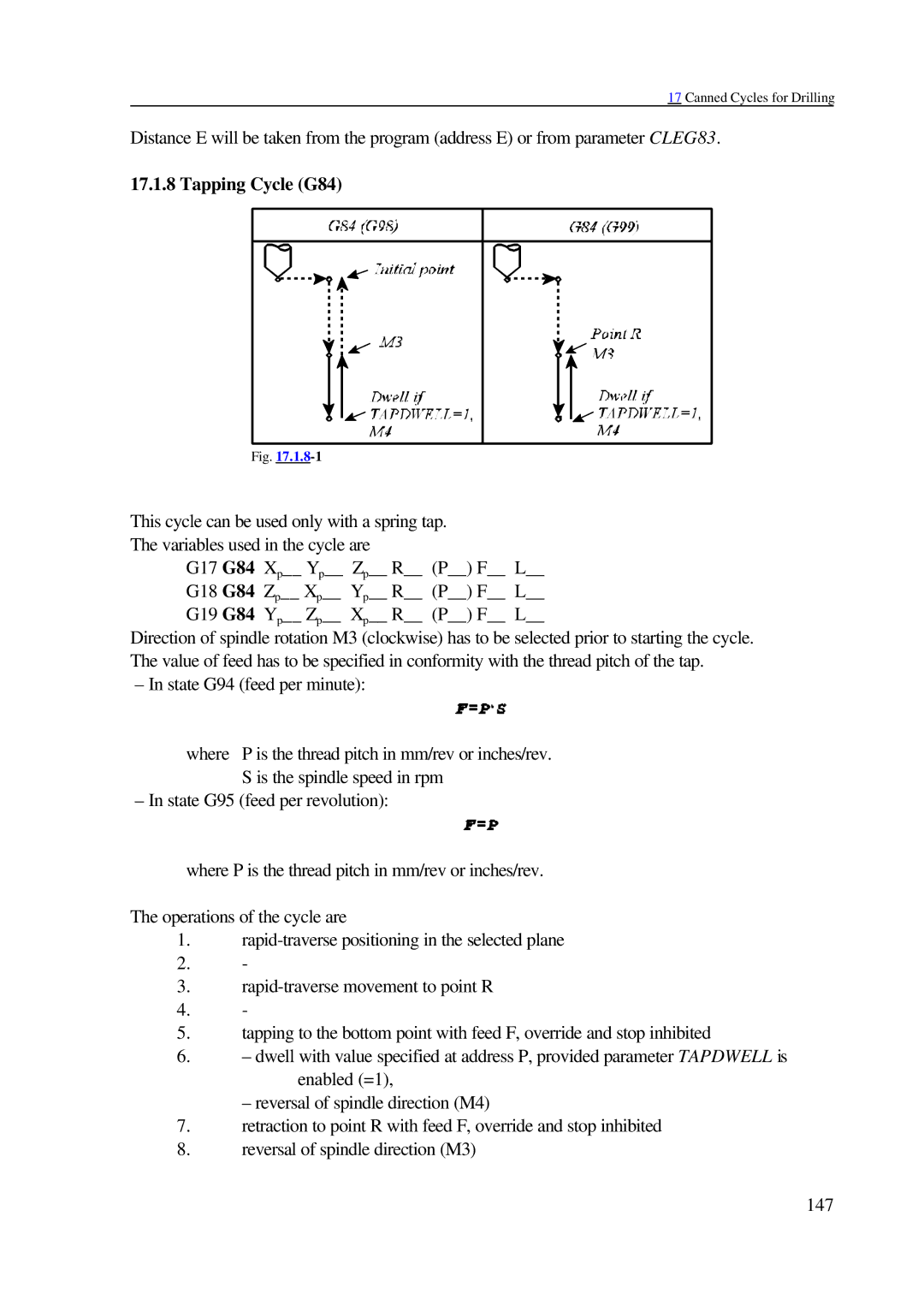

17.1.8 Tapping Cycle (G84)

Fig.

This cycle can be used only with a spring tap. The variables used in the cycle are

G17 G84 Xp__ Yp__ Zp__ R__ (P__) F__ L__ G18 G84 Zp__ Xp__ Yp__ R__ (P__) F__ L__ G19 G84 Yp__ Zp__ Xp__ R__ (P__) F__ L__

Direction of spindle rotation M3 (clockwise) has to be selected prior to starting the cycle. The value of feed has to be specified in conformity with the thread pitch of the tap.

– In state G94 (feed per minute):

where P is the thread pitch in mm/rev or inches/rev. S is the spindle speed in rpm

– In state G95 (feed per revolution):

where P is the thread pitch in mm/rev or inches/rev.

The operations of the cycle are

1.

2.-

3.

4.-

5.tapping to the bottom point with feed F, override and stop inhibited

6.– dwell with value specified at address P, provided parameter TAPDWELL is enabled (=1),

– reversal of spindle direction (M4)

7.retraction to point R with feed F, override and stop inhibited

8.reversal of spindle direction (M3)

147