1Introduction

1.2 Fundamental Terms

The Interpolation

The control system can move the tool along straight lines and arcs in the course of mach- ining. These activities will be hereafter referred to as "interpolation".

Tool movement along a straight line:

program:

G01 Y__

X__ Y__

Fig. |

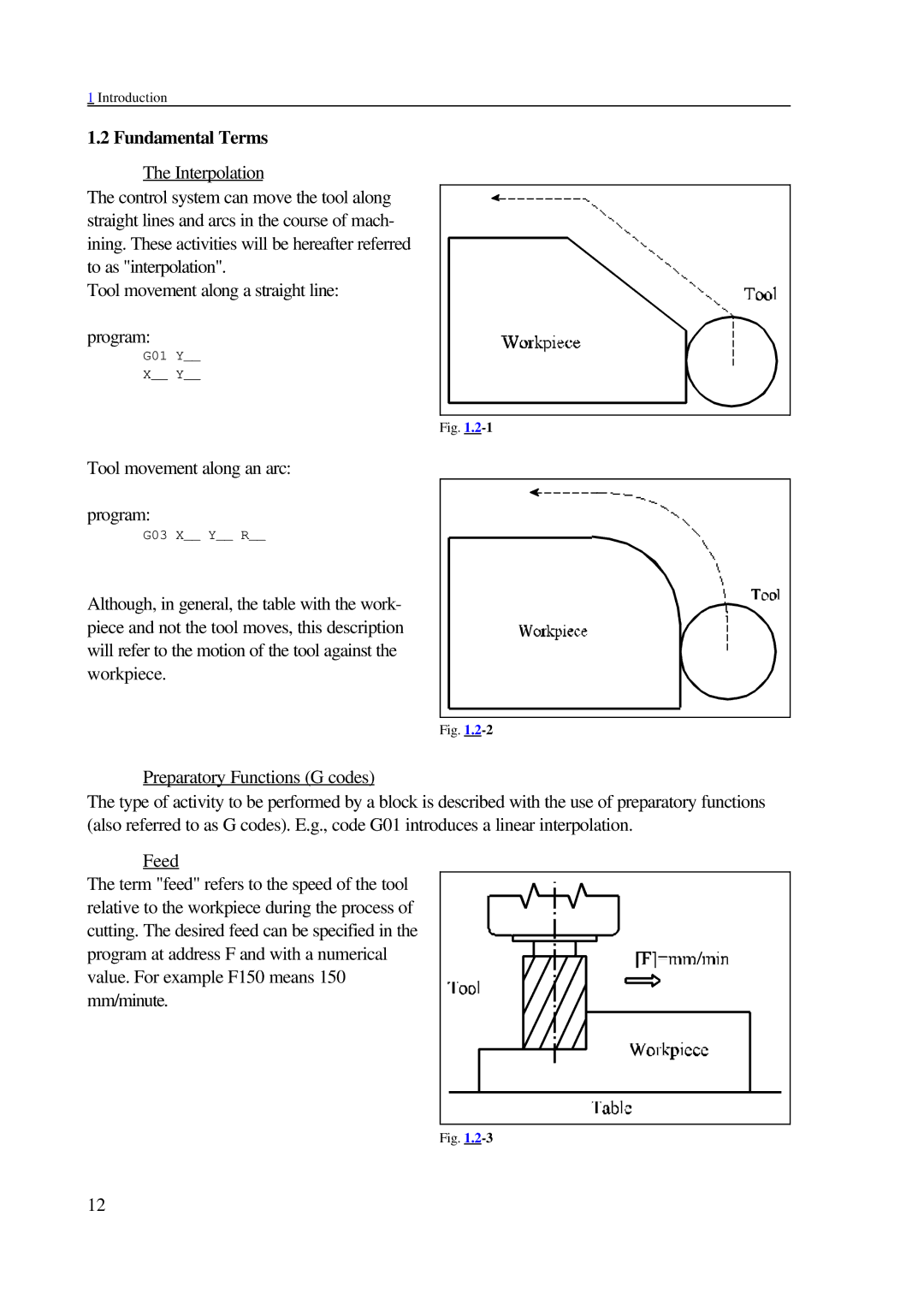

Tool movement along an arc:

program:

G03 X__ Y__ R__

Although, in general, the table with the work- piece and not the tool moves, this description will refer to the motion of the tool against the workpiece.

Fig.

Preparatory Functions (G codes)

The type of activity to be performed by a block is described with the use of preparatory functions (also referred to as G codes). E.g., code G01 introduces a linear interpolation.

Feed

The term "feed" refers to the speed of the tool relative to the workpiece during the process of cutting. The desired feed can be specified in the program at address F and with a numerical value. For example F150 means 150 mm/minute.

Fig.

12