4 The Interpolation |

| |

An example of programming a |

| |

N50 | G90 G0 X0 Y0 S100 M4 |

|

N55 | Z2 |

|

N60 | G33 |

|

N65 | M19 |

|

N70 | G0 X5 |

|

N75 | Z2 M0 |

|

N80 | X0 M4 |

|

N85 | G4 P2 |

|

N90 | G33 |

|

... |

|

|

Explanation: |

|

|

N50, N55 - Moving the tool over the center of hole, starting |

| |

the spindle in |

| |

N60 - First |

| |

N65 - Oriented spindle stop (the spindle is stopped in a |

| |

fixed position), |

| |

N70 - Tool retraction along axis X, |

| |

N75 - Tool retraction to the top of hole, programmed stop, |

| |

the operator adjust the tool to the next |

| |

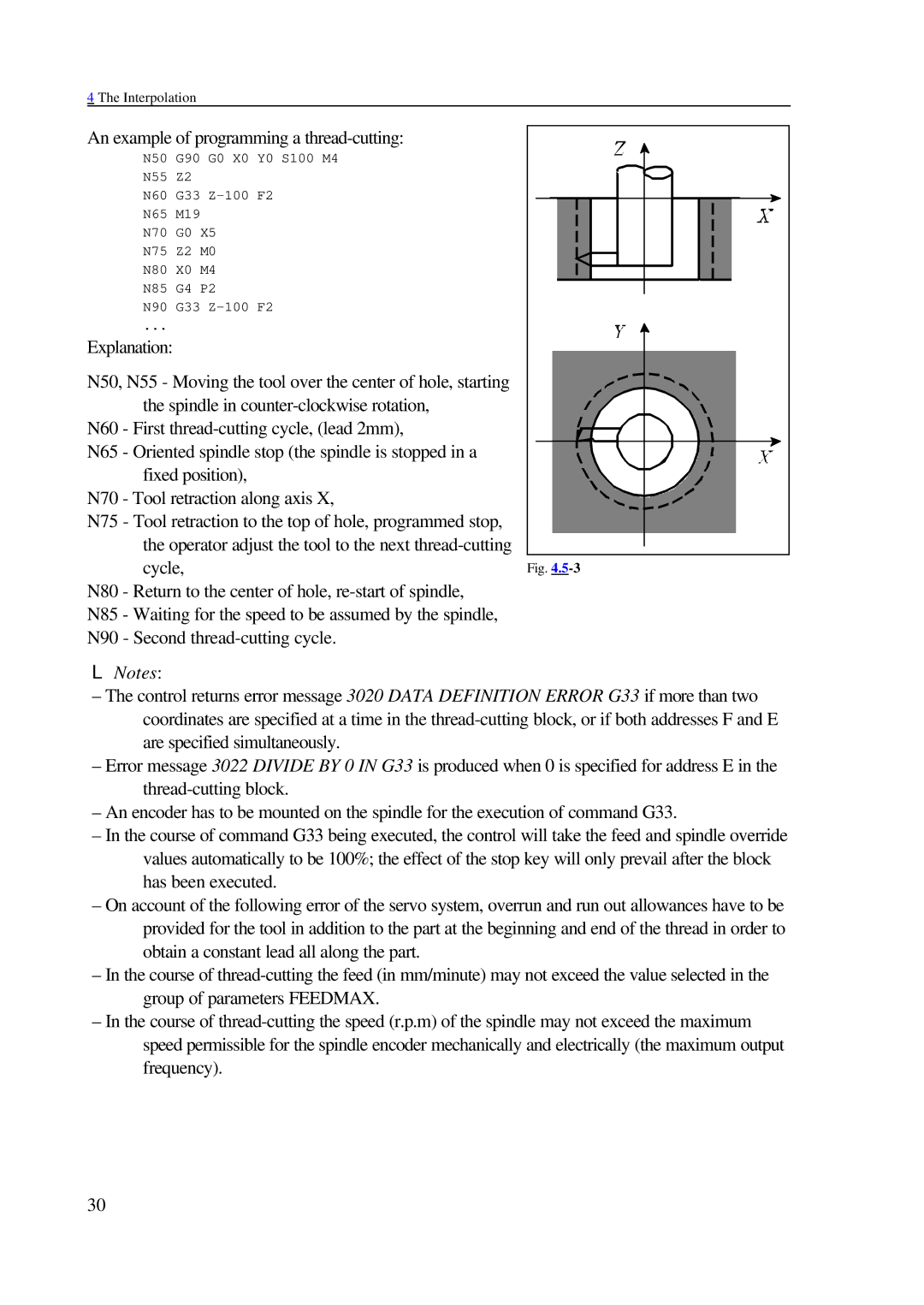

cycle, | Fig. | |

N80 - Return to the center of hole, |

| |

N85 - Waiting for the speed to be assumed by the spindle, |

| |

N90 - Second |

| |

LNotes:

–The control returns error message 3020 DATA DEFINITION ERROR G33 if more than two coordinates are specified at a time in the

–Error message 3022 DIVIDE BY 0 IN G33 is produced when 0 is specified for address E in the

–An encoder has to be mounted on the spindle for the execution of command G33.

–In the course of command G33 being executed, the control will take the feed and spindle override values automatically to be 100%; the effect of the stop key will only prevail after the block has been executed.

–On account of the following error of the servo system, overrun and run out allowances have to be provided for the tool in addition to the part at the beginning and end of the thread in order to obtain a constant lead all along the part.

–In the course of

–In the course of

30