20 Custom Macro

E = width of cutting, in percent of milling diameter

with + sign, machining in

Two types of information can be specified at address E. The value of E defines the width of cutting in percent of milling diameter. Unless it is specified, the control will automatically assume +83%. The control can modify the data specified at address E, depending on the width of pocket, in order to obtain a uniformcutting in milling a particular level. Such a modification may, however, be a reduction only. The sign of address E will define the direction of milling. When E+, i.e., it is positive, the machining will be carried out in

Q = depth of cut

The depth of cut can be specified at address Q in the applicable units of measure (mm or inches). Depending on the depth of pocket, the control may override the program value in order to obtain a uniform distribution of cuts. Such a modification may, however, be a reduction only.

F = feed

The feed applied in the cycle can be specified at address F. Unless F is given a value, the modal F value will be adopted. 50% of the F value will be applied

–when a level begins to be milled, and a depth of cut (Q) is drilled,

–when milling the pocket longitudinally as long as the Q is loaded on both sides. M S T = function

A function M, S, T can be specified in the block calling the procedure of pocket milling, which will be executed by the control prior to commencement of milling.

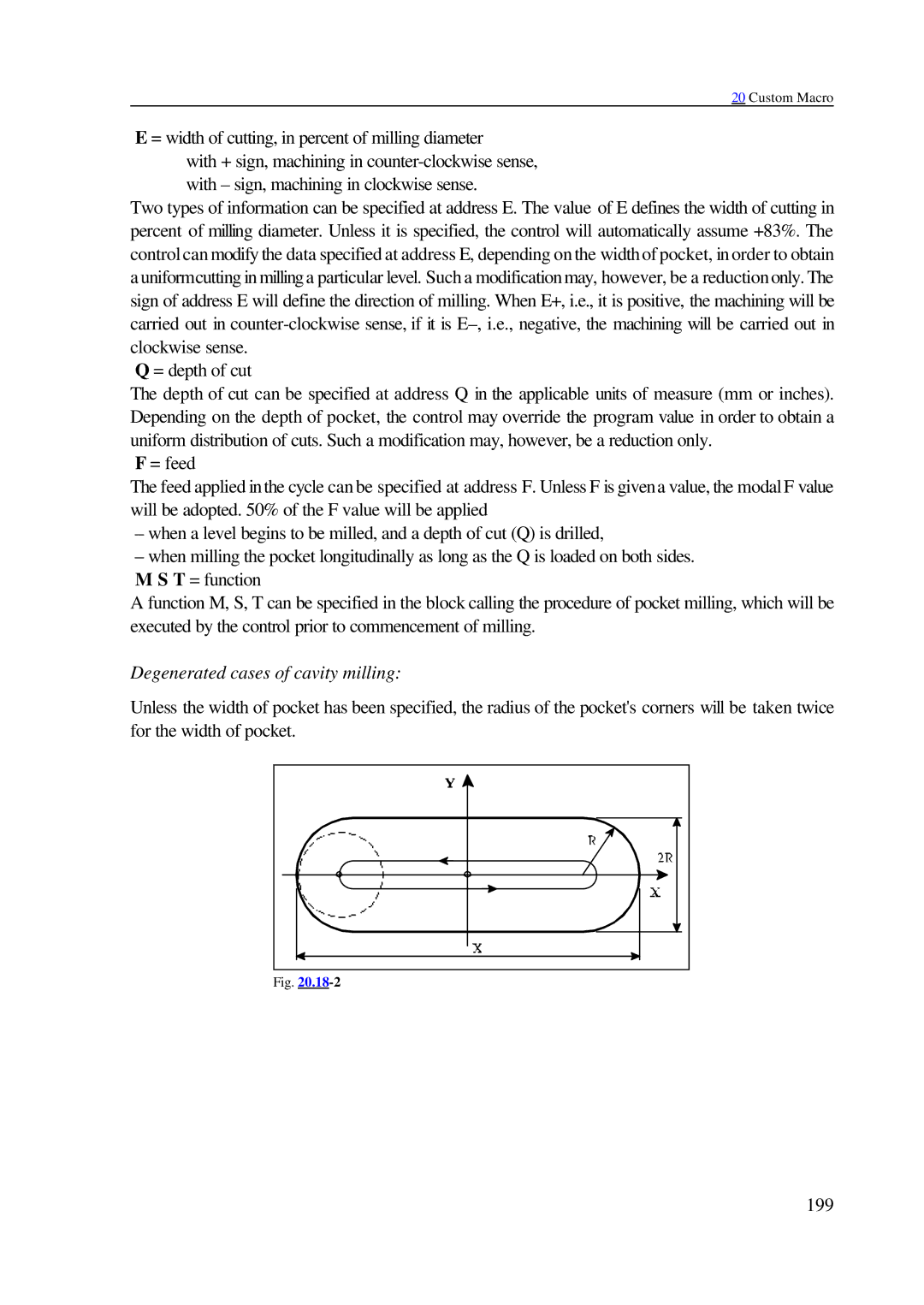

Degenerated cases of cavity milling:

Unless the width of pocket has been specified, the radius of the pocket's corners will be taken twice for the width of pocket.

Fig. |

199