6 The Feed

The control is monitoring the changes in tangential speeds. This is necessary to attain the commanded speed in a process of continuous acceleration, if necessary, through several blocks. The acceleration to the new feed (higher than the

previous one) is commenced by the control

invariably in the execution of the particular block, in which the new feed value is specified. That process may, if necessary, cover several

blocks. Deceleration to the new feed value (lower than the previous one) will be started by the control in an appropriate preceding block so

that the machining will be started with the programmed speed in the particular block, in which the new feed value is specified.

When moving manually by using jog keys or

handwheel, again linear acceleration/deceleration will be performed. Their values will be defined for each axis by parameters ACC1 through ACC8.

6.4 Feed Control Functions

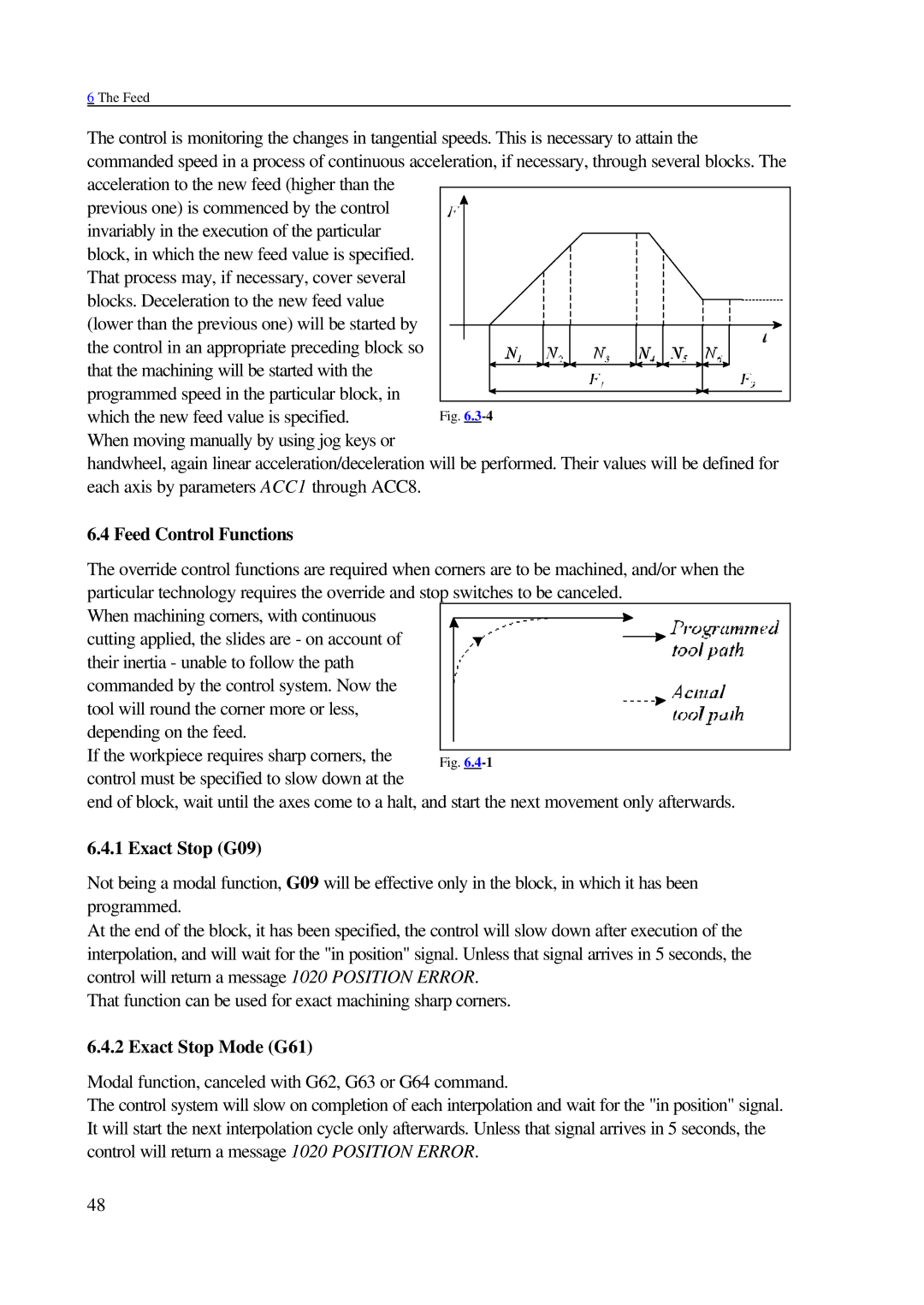

The override control functions are required when corners are to be machined, and/or when the particular technology requires the override and stop switches to be canceled.

When machining corners, with continuous

cutting applied, the slides are - on account of their inertia - unable to follow the path

commanded by the control system. Now the tool will round the corner more or less, depending on the feed.

If the workpiece requires sharp corners, the control must be specified to slow down at the

end of block, wait until the axes come to a halt, and start the next movement only afterwards.

6.4.1 Exact Stop (G09)

Not being a modal function, G09 will be effective only in the block, in which it has been programmed.

At the end of the block, it has been specified, the control will slow down after execution of the interpolation, and will wait for the "in position" signal. Unless that signal arrives in 5 seconds, the control will return a message 1020 POSITION ERROR.

That function can be used for exact machining sharp corners.

6.4.2 Exact Stop Mode (G61)

Modal function, canceled with G62, G63 or G64 command.

The control system will slow on completion of each interpolation and wait for the "in position" signal. It will start the next interpolation cycle only afterwards. Unless that signal arrives in 5 seconds, the control will return a message 1020 POSITION ERROR.

48