SM320F2812-HT specifications

The Texas Instruments SM320F2812-HT is a highly capable digital signal processor (DSP) specifically designed for high-performance and real-time applications in harsh environments. This part of the C2000 family of microcontrollers caters to applications in areas such as industrial automation, motor control, and power conversion, where reliability and durability under extreme temperature conditions are paramount.One of the standout features of the SM320F2812-HT is its robust architecture based on a 32-bit fixed-point core. This allows for efficient execution of complex algorithms while maintaining a high processing speed. The processor operates at clock speeds of up to 150 MHz, enabling it to handle multiple tasks simultaneously with minimal latency.

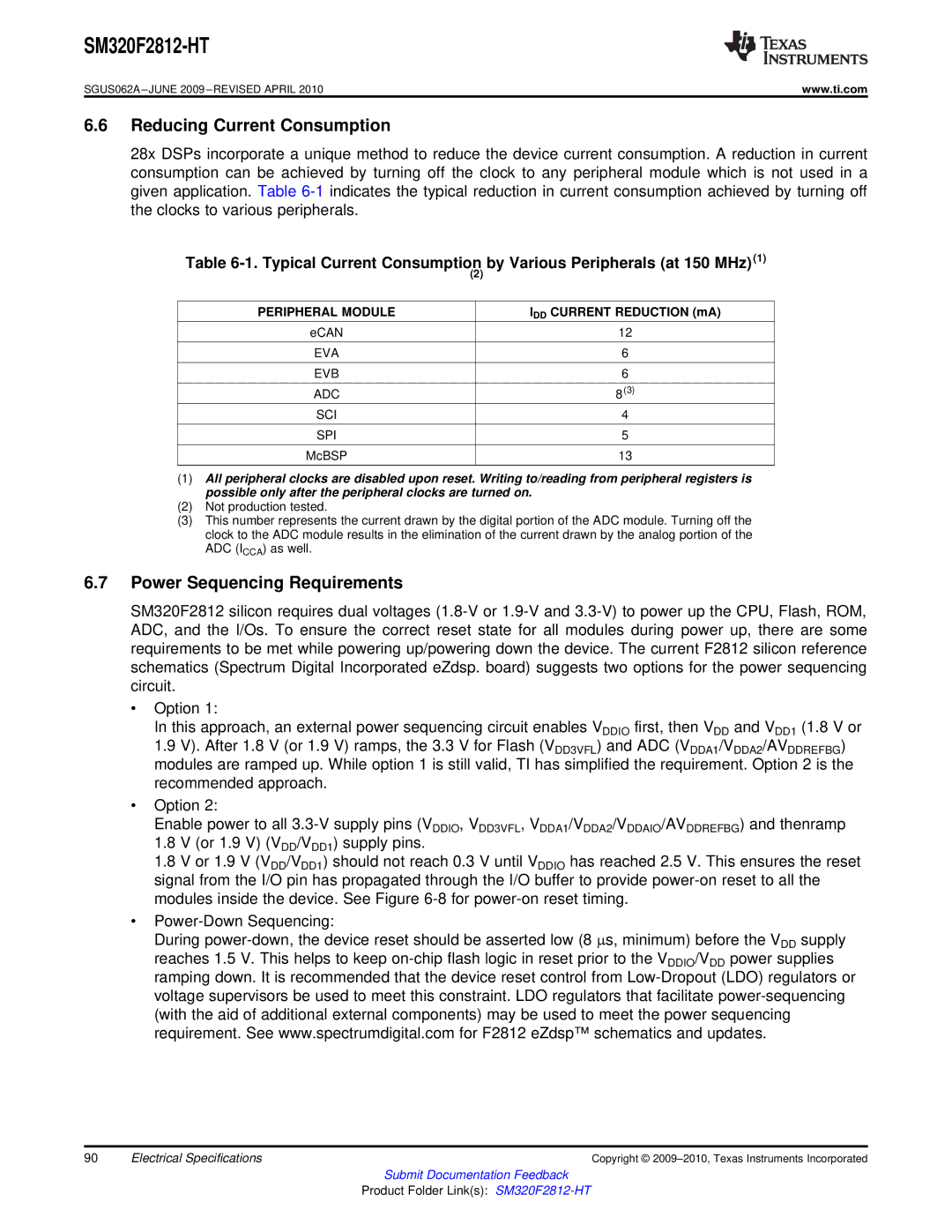

The SM320F2812-HT boasts an impressive memory configuration that includes up to 128 KB of flash memory and 4 KB of RAM. The integrated memory supports efficient data handling and storage, making it ideal for demanding applications that require quick access to critical information. The device also features various peripherals, including analog-to-digital converters (ADCs), pulse width modulation (PWM) modules, and serial communication interfaces, which enhance its functionality in real-time processing and control tasks.

Furthermore, this DSP employs advanced control algorithms and supports various communication protocols, allowing it to interoperate seamlessly with other devices within a system. Its capabilities are further enhanced by Texas Instruments’ extensive development tools and software libraries, which enable developers to accelerate design cycles and improve overall efficiency.

With its high temperature rating, the SM320F2812-HT is designed to operate within a temperature range from -40°C to 125°C, making it particularly well-suited for use in automotive, aerospace, and other rugged environments where traditional components might fail. The high reliability and endurance of this microcontroller make it a preferred choice among engineers looking for durable solutions without compromising performance.

In summary, the Texas Instruments SM320F2812-HT represents a powerful blend of processing capabilities, memory architecture, and environmental resilience. Its features make it a go-to option for developers in search of a robust DSP for real-time applications, ensuring that it meets the rigorous demands of various industrial sectors while delivering consistent performance.