Tank Hub

Reference Manual

Rosemount

Page

Spare Parts

Rosemount Tank Hub

Rosemount

Page

SECTION 4 Configuration

Table of Contents

SECTION 1 Introduction SECTION 2 Overview SECTION 3 Installation

SECTION Service and Troubleshooting

APPENDIX C Advanced Configuration

SECTION 5 Operation

APPENDIX A Reference Data APPENDIX B Product Certifications

TOC-3

TOC-4

1.1 SAFETY MESSAGES

Section

Introduction

page

1.2 SYMBOLS

Section 3 Installation

Section 4 Configuration

Section 6 Service and Troubleshooting

Appendix C Advanced Configuration

1.4 TECHNICAL DOCUMENTATION

1.7 PACKING MATERIAL 1.7.1 Reuse and Recycling 1.7.2 Energy recovery

1.6 PRODUCT RECYCLING/DISPOSAL

Reference Manual

Overview

2.1 INTRODUCTION

Reference Manual

2.1.1 Communication

Smart Wireless

THUMAdapter

2.2 COMPONENTS

2.3 SYSTEM OVERVIEW

1 See documents IEC 61158-2 and IEC/TS

CONTROL CUSTODY

NON-HAZARDOUS AREA HAZARDOUS AREA

TRANSFER / INVENTORY TANK GAUGING

NON-HAZARDOUS AREA

HAZARDOUS AREA

TankMaster HMI Software

Rosemount 2160 Field Communication Unit

Rosemount 2410 Tank Hub

Rosemount 5900S Radar Level Gauge

Rosemount 5300 Guided Wave Radar

Rosemount 5400 Radar Level Transmitter

Rosemount 2240S Multi-Input Temperature Transmitter

Rosemount 2230 Graphical Field Display

Reference Manual

2.4 INSTALLATION PROCEDURE

Mount the See “Mechanical Installation” on page Wire the

3.1 SAFETY MESSAGES

Installation

3.2 INSTALLATION CONSIDERATIONS

3.3 MECHANICAL INSTALLATION

3.3.1 Pipe Mounting

1 - 2 inches Bracket

Bracket

3.3.2 Wall Mounting

94 mm

70 mm

Ø 9 mm

3.4.1 Cable Entries

3.4 ELECTRICAL INSTALLATION

3.4.2 Power Supply 3.4.3 Cable Selection for Power Supply

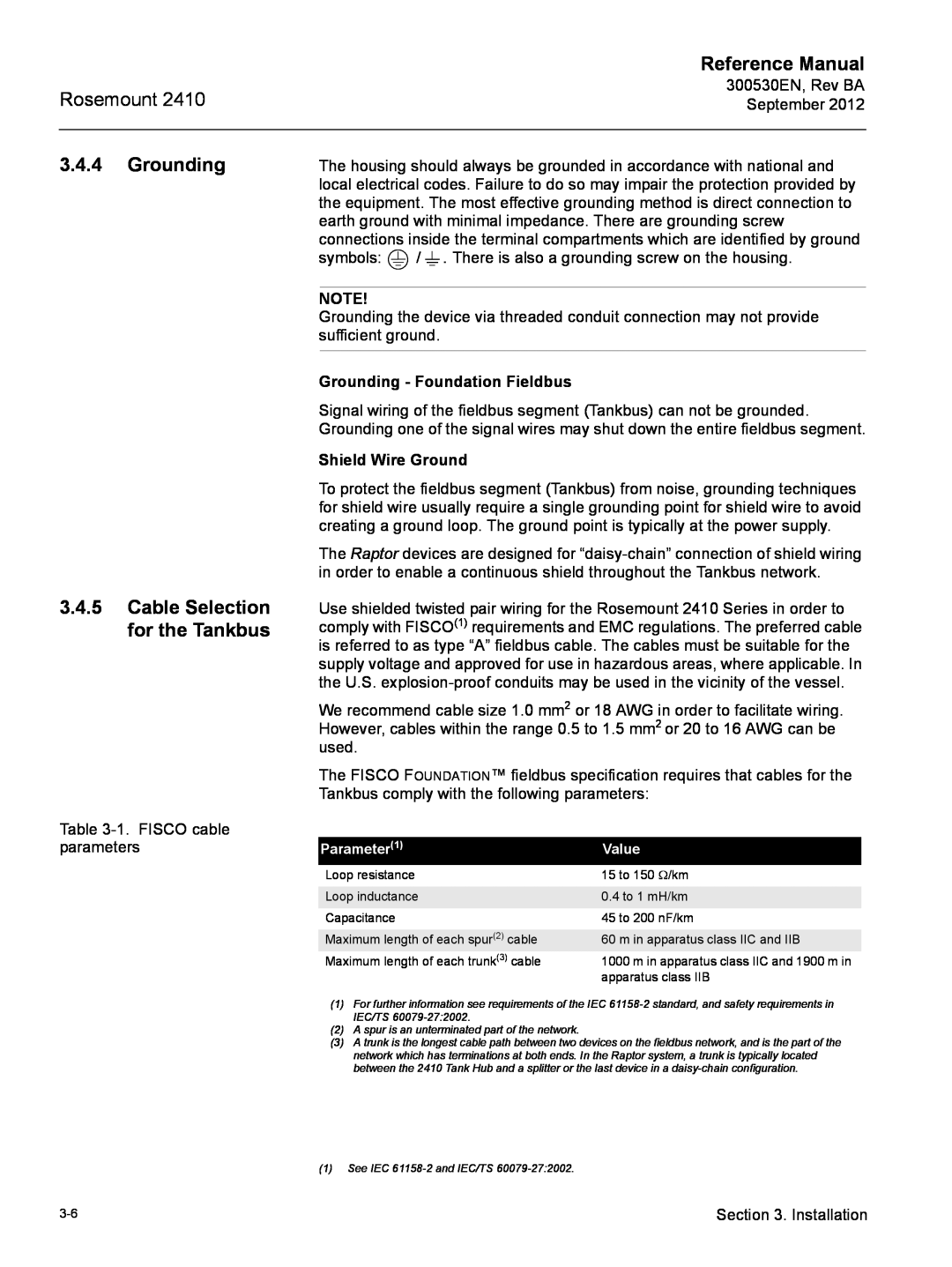

Grounding - Foundation Fieldbus

Shield Wire Ground

3.4.4 Grounding 3.4.5 Cable Selection for the Tankbus

3.4.6 Power Budget

Power consumption

Field device

2 Maximum five Rosemount 5300 or 5400 level transmitters

Fieldbus Segment Design

3.4.7 Tankbus

Termination

Typical installation

Typical loop

Maximum Current

resistance

Example

5400 Radar Level

Segment

Tankbus Segment Coupler

Trunk OUT

Examples

Trunk IN

3-14

Segment coupler with active terminator end of trunk

Spur60 m

2240S Multi-input Temperature

3.4.8 Typical Installations

enabled on the

Pressure transmitter

Secondary 2410 Tank Hub

Secondary Tank Hub

is connected to the

2240S Multi-input

644 Temperature

Segment coupler with integrated bus terminator

Reference Manual

Rosemount

Reference Manual

Rosemount

Reference Manual

RS485 Bus

3.4.9 Cabling for the TRL2/RS485 Bus

TRL2 Bus

3.4.10 Non-IS Connection

Non-IS compartment Wiring with drip loop Ground screw

Safety locking screw Cable entries

Terminal block Ground screws

Conductor Recommendations

Stripping length 10 mm Conductor cross-sectional area, see Table

3-24

Terminal block

Conductor

Power Supply

3.4.11 Non-IS Terminal Block

Primary Communication Bus

Secondary Communication Bus

Relay Outputs

Non-IS Terminal Block for SIL Safety Systems

SIL Alarm Relay B

SIL Alarm Relay A

XP/Exd/Exe Ground screw Ground screws SIL Relay

Cable entries

3.4.12 IS Connection

IS compartment Wiring with drip loop Terminal block Ground screws

Optional Secondary Bus

3.4.13 Intrinsically Safe Terminal Block

Tankbus

IS Terminal Block for SIL Safety Systems

3.4.14 Wiring Diagrams

ROSEMOUNT

Terminal block on intrinsically safe side

Intrinsically safe Tankbus

3-32

Radar Level Gauge

Rosemount

3-34

Rosemount 2410 Series

Configuration

4.1 SAFETY MESSAGES

4.3 CONFIGURATION TOOLS

4.2 INTRODUCTION

4.4 BASIC CONFIGURATION OF A ROSEMOUNT

Communication

Tank Database

Device Tags

See Appendix C Advanced Configuration for more information

4.5 ADVANCED CONFIGURATION

4.6 CONFIGURATION USING TANKMASTER WINSETUP

Install New

4.6.1 Installation Wizard

4.6.2 Advanced Configuration

2410Temp is automatically added

4.6.3 FCU 2160 Configuration

2410Level

5.1 SAFETY MESSAGES

Operation

Measurement value Toggling between measurement variable and

5.2 INTEGRAL DISPLAY

measurement unit Write protection switch

Presentation on display

Variable

Description

5.3 START-UP INFORMATION

Example

Code

“ERROR” indication Fail/Error code

Error

5.5 LED

5.5.1 LED Start-Up Information

Error LED Red Status LED Yellow Power On LED Green

occurs, the Error LED flashes a sequence that corresponds to

5.5.2 Error LED

Error LED Red

Other memory error

Seconds

5.6 SPECIFYING DISPLAY VARIABLES

Section 6 Service and Troubleshooting

6.1 SAFETY MESSAGES

6.2 SERVICE

6.2.1 Viewing Input and Holding Registers

6.2.2 Editing Holding Registers

Predefined All

A removable tag provided with the device lets you identify the

6.2.3 Device Live List

1. Start the TankMaster WinSetup program

6.2.4 Configuration Backup

6.2.5 Configuration Recovery

6.2.6 Diagnostics

The Configure button lets you open the Configure Diagnostic Registers window, allowing you to change the list of registers to be displayed in the View Diagnostic Registers window

6.2.7 Device Software Upgrade

Reference Manual

6.2.8 Write Protection

Write Protect

6.2.9 Write Protection Switch

Write protection switch

Average Temperature Total Observed Volume Observed Density

Simulation Parameter

Simulation Holding Register

HR3868 HR3994 HR3976

Advanced Simulation

Simulation mode active

6.2.11 Testing the Relays

6.2.12 Relay Output Configuration

Front cover

Relay K1 NC - NO

Relay K2 NC - NO

6.2.13 Loading the Default Database

To load the default database

6.2.14 Logging Measurement Data

6.3 TROUBLESHOOTING

Symptom

See the Raptor System Configuration Manual

Possible cause

Check that there are no multiple shield grounding points

Check that the total current consumption of the devices

Check Device Status input register, see “Device Status”

open the FCU Properties/Slave Database window

See the Rosemount 5900S Reference Manual

Advanced Parameter Source Configuration tab. Check

WinSetup Tank View window, and

In TankMaster Winsetup, right-click the ATD device icon

6-22

Double-click the Value field to open the Expanded Bitfield window

6.3.1 Device Status

The device is write protected with a switch

6.3.2 Warning Messages

Source Configuration tab

6-26

6.3.3 Error Messages

application software. Try to reprogram the

Reference Manual

6-28

A.1 SPECIFICATIONS

Appendix A

Reference Data

page A-1

Analog input/output electrical

Housing material

A.2 DIMENSIONAL DRAWINGS

254 mm 164 mm 193 mm

A.3 ORDERING INFORMATION

For connection to a 3rd party system For connection to a 3rd party system

1 Requires Secondary Fieldbus Pos 5, code A-F, W, 0

2 Requires Primary Fieldbus Pos 4 code R or

4 Requires Relay Output Pos 6 code 0 or F

6 Requires Secondary Fieldbus Pos 5, code 0 or F

B.1 SAFETY MESSAGES

Appendix B Product Certifications

B.2 EU CONFORMITY

B.3.1 Factory Mutual US Approvals

E5 FISCO Power Supply

B.3 HAZARDOUS LOCATIONS CERTIFICATIONS

HART/4-20 mA ENTITY IS I/O Option

E6 FISCO Power Supply

B.3.2 Factory Mutual Canadian Approvals

HART/4-20 mA ENTITY IS I/O Option

B.3.3 European ATEX Directive Information

FISCO Power Supply

B.3.4 IECEx Approval

B-10

B.4 APPROVAL DRAWINGS

B-11

B-12

Appendix C Advanced Configuration

C.1 SAFETY MESSAGES

Reference Manual

C.2 ADVANCED CONFIGURATION IN WINSETUP

1. In the Configuration field, change from Standard to Non Standard

C.3 PRIMARY BUS

Configuration window

C.4 SECONDARY BUS

Figure C-3. Secondary Bus Configuration window

Using two/three relay zones

C.5 RELAY OUTPUT

First and second set points

Hysteresis

Switch Delay

Virtual Relay States

Virtual Relay Output

Source

Normally Open

Relay output configuration

Normally Closed

Relay Zones

C.6 HYBRID DENSITY CALCULATION

C-10

C-11

Configuration

C.6.1 Hybrid Density

1. Open the 2410 Tank Hub/Configuration window

C-12

C-13

C-14

C.7 VOLUME CONFIGURATION

Strapping Table

Holding and Input Registers for Volume Configuration

Note the Volume Offset is added when predefined tank

C-16

C.8 ARITHMETIC OPERATIONS

Tank measurement variable in which the result is stored

Reference Manual

C.8.1 Delta Level Calculation

C-19

C-20

Index

Numerics

Secondary Communication Bus

Index-2

Page

All other marks are the property of their respective owners

FOUNDATION is a trademark of the Fieldbus Foundation

Monel is a trademark of International Nickel Co