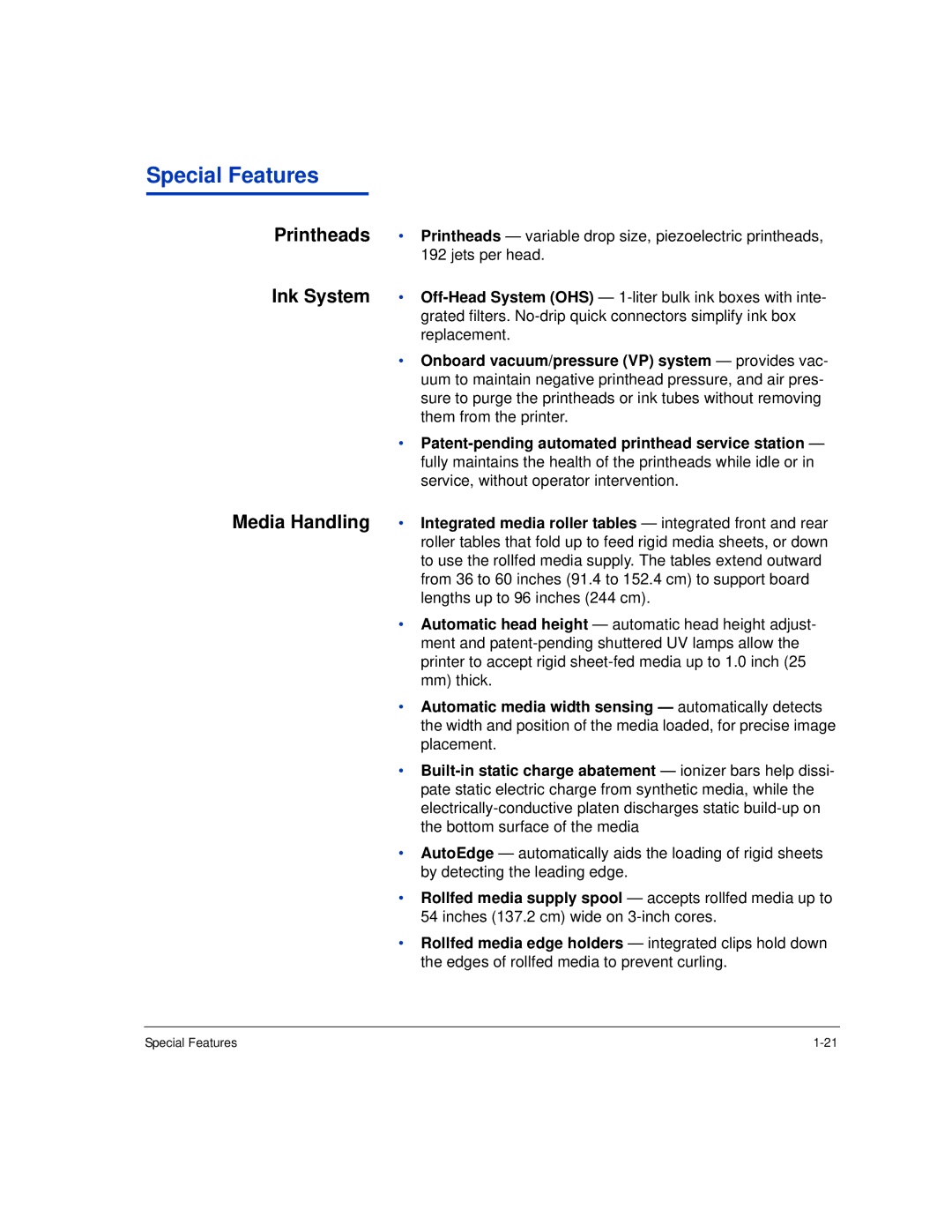

Special Features

Printheads

Ink System

Media Handling

•Printheads — variable drop size, piezoelectric printheads, 192 jets per head.

•

•Onboard vacuum/pressure (VP) system — provides vac- uum to maintain negative printhead pressure, and air pres- sure to purge the printheads or ink tubes without removing them from the printer.

•

•Integrated media roller tables — integrated front and rear roller tables that fold up to feed rigid media sheets, or down to use the rollfed media supply. The tables extend outward from 36 to 60 inches (91.4 to 152.4 cm) to support board lengths up to 96 inches (244 cm).

•Automatic head height — automatic head height adjust- ment and

•Automatic media width sensing — automatically detects the width and position of the media loaded, for precise image placement.

•

•AutoEdge — automatically aids the loading of rigid sheets by detecting the leading edge.

•Rollfed media supply spool — accepts rollfed media up to 54 inches (137.2 cm) wide on

•Rollfed media edge holders — integrated clips hold down the edges of rollfed media to prevent curling.

Special Features |