OPERATION |

Return to Section TOC Return to Master TOC

LASER SCREEN

(Live Action Student Evaluation Report)

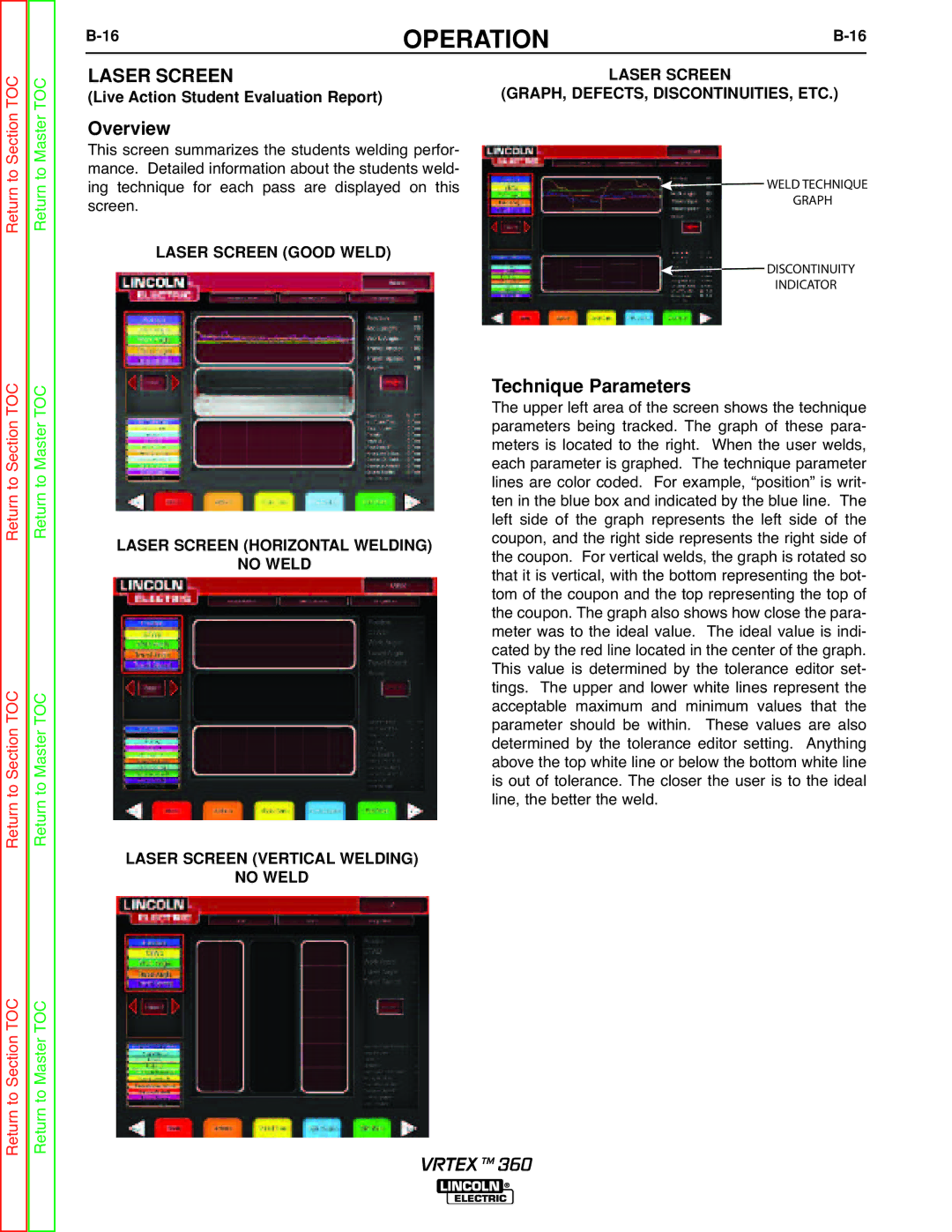

ThisOverviewscreen summarizes the students welding perfor- mance. Detailed information about the students weld- ing technique for each pass are displayed on this screen.

LASER SCREEN (GOOD WELD)

LASER SCREEN

(GRAPH, DEFECTS, DISCONTINUITIES, ETC.)

![]()

![]() WELD TECHNIQUE

WELD TECHNIQUE

GRAPH

![]()

![]() DISCONTINUITY

DISCONTINUITY

INDICATOR

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

LASER SCREEN (HORIZONTAL WELDING)

NO WELD

LASER SCREEN (VERTICAL WELDING)

NO WELD

Theechniqueupper leftParametersarea of the screen shows the technique parameters being tracked. The graph of these para- meters is located to the right. When the user welds, each parameter is graphed. The technique parameter lines are color coded. For example, “position” is writ- ten in the blue box and indicated by the blue line. The left side of the graph represents the left side of the coupon, and the right side represents the right side of the coupon. For vertical welds, the graph is rotated so that it is vertical, with the bottom representing the bot- tom of the coupon and the top representing the top of the coupon. The graph also shows how close the para- meter was to the ideal value. The ideal value is indi- cated by the red line located in the center of the graph. This value is determined by the tolerance editor set- tings. The upper and lower white lines represent the acceptable maximum and minimum values that the parameter should be within. These values are also determined by the tolerance editor setting. Anything above the top white line or below the bottom white line is out of tolerance. The closer the user is to the ideal line, the better the weld.

Return to Master TOC

Return to Section TOC

VRTEX TM 360