Xerox Document Services Platform Series

USA

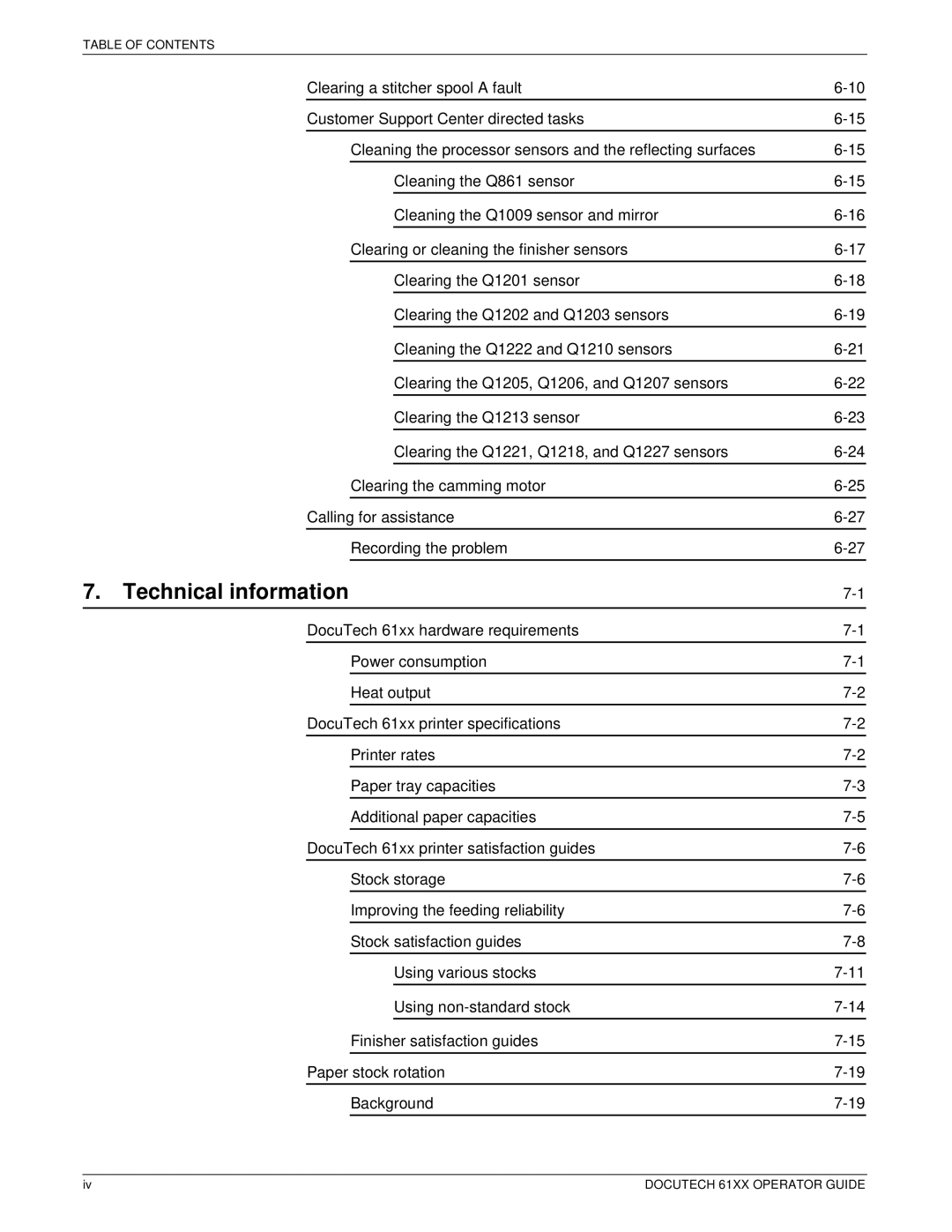

Table of Contents

Table of Contents

Routine maintenance

Problem solving

Technical information

Supplies

Table of Contents Docutech 61XX Operator Guide

Vii

Viii

System safety

Laser safety

Ozone safety

Operation safety

European Union declaration of conformity

Safety notices

Safety notices

Safety notices

Regulation

Question What is the Electricity at Work Regulation?

Electricity at Work Regulation UK

Check your understanding

Manufacturers or suppliers of such electrical systems

Answer

Places a duty on all employers and self-employed persons to

Question Is Xerox equipment safe? Answer

Question I require records of all tests

Your responsibility

Additional queries

Extra Low Voltage safety approval

FCC . . . USA

Radio frequency

Industry Canada requirements

European Union

Certifications DocuTech 61xx Operator Guide

Powering down the System

About this guide

Contents

Conventions

Introduction

Introduction DocuTech 61xx Operator Guide

System components

Electronic reprographics process

System

System Hardware

DocuTech 6100/6115/6135 system hardware

DocuSP controller

DocuTech 6155/6180 system hardware

Printer

Processor

Dry ink cartridge

Paper trays

Electrical module

Photoreceptor

Fuser agent reservoir

Ground fault protector

Laser

Inverter duplex tray

Interposer

Interposer components

Upper turn transport

Upper entrance transport

Upper vertical transport

Tray

Lower exit transport

Lower entrance transport

Lower turn transport

Lower vertical transport

Finisher components

Bindexer

Binder

Stitcher

Stacker

Top tray

Paper paths

Paper path areas

System components DocuTech 61xx Operator Guide

Adding paper

Adding paper to tray 1 or

Preparing the paper tray

Positioning the stack

Adding paper to trays 3, 4, or

Moving the guides

Cleaning and maintenance overview

Precautions you should take

Cleaning the binder

Opening the binder drawer

Binder platen cleaner

Cleaning the binder tape guides

Cleaning the tape guides Cleaning the binder platen

Cleaning the binder platen Cleaning the flappers

Cleaning the flappers Cleaning the calipers

Maintaining the printer

Replacing the dry ink cartridge

Routine maintenance

11. Removing the empty cartridge

12. Inserting and latching the cartridge

Replacing the dry ink waste container

14. Removing the full waste container

15. Placing the cap on the waste container

Adding fuser agent

17. Opening the fuser drawer

18. Preparing to add fuser agent

19. Adding the fuser agent

20. Closing the fuser drawer

Replacing the stitcher spool a

21. Releasing the stitcher head

23. Removing the wire from the tubing

24. Rewinding the remaining wire

26. Removing the stitcher spool pin

27. Replacing the pin

28. Removing the paper wrapper

Storing the binder tape reels

30. Storing binder tape in a cool, dry place

Replacing the binder tape reel

32. Opening the binder drawer

33. Removing the tape

35. Locking the reel

36. Threading the tape through the tape feeder

38. Feeding the tape manually

Adjusting the binder tape registration

40. Locating the binder tape knob

41. Adjusting the tape position up

Adjusting the heavy paper levers

43. Raising the levers

Adjusting for paper curl

Measuring the paper curl

45. Measuring the paper curl

Routine maintenance DocuTech 61xx Operator Guide

Recommended

Adjusting the decurler lever

46. Locating the decurler lever

Problem solving

How problems are displayed

Printer faults and fault windows

When a fault occurs

Resolving a recurring problem

Resolving a processor problem

Missing sheets in a set

Sheets from the fuser

Resolving a processor problem

Resolving an interposer problem

Resolving a finisher problem

Resolving a finisher problem

Clearing a binder tape fault

Clearing a stitcher spool a fault

Stitcher head release handle

Cutting the wire

Measuring bracket

Removing the wire fragments

Customer Support Center directed tasks

Area 4 green handle

Cleaning the Q1009 sensor and mirror

Clearing or cleaning the finisher sensors

Q1009 sensor location

Folding the paper

Clearing the Q1201 sensor

10. Locating the Q1201 sensor

Clearing the Q1202 and Q1203 sensors

11. Locating the Q1202 and Q1203 sensors

Cleaning the Q1222 and Q1210 sensors

13. Locating the Q1222 and Q1210 sensors

14. Locating the Q1222 and Q1210 sensors

Clearing the Q1205, Q1206, and Q1207 sensors

15. Locating the Q1205, Q1206, and Q1207 sensors

Clearing the Q1213 sensor

16. Q1213 sensor

Clearing the Q1221, Q1218, and Q1227 sensors

17. Locating the Q1221, Q1218, and Q1227 sensors

Clearing the camming motor

18. Opening the fuser drawer

Recording the problem

Calling for assistance

Problem solving

Power consumption

DocuTech 61xx hardware requirements

Printer rates Print rate per

DocuTech 61xx printer specifications

Heat output

Minute

Print rate per minute

Paper tray capacities

JIS B4

JIS B4

DocuTech 61xx printer satisfaction guides

Stock storage

Improving the feeding reliability

Technical information

Satisfaction guide for paper tray

Satisfaction guide for paper tray

Satisfaction guide for 2-sided printing

Using various stocks

10. Satisfaction guide for various stocks

Drilled

10. Satisfaction guide for various stocks

Using non-standard stock

11. Stock width impact on system performance

12. Stock length impact on system performance

Finisher satisfaction guides

13. Stacker capacity

14. Stitcher satisfaction guide

15. Binder satisfaction guide

16. Top tray satisfaction guide

Paper stock rotation

Background

Limitations

17. Common US paper sizes

18. Common sizes used in Europe, Japan, Canada, etc

19. Other paper sizes that can be rotated

Rotatable and non-rotatable sizes as loaded Media sizes

Supplies to keep in stock

Supplies ordered from the Supply Order Representative

Supplies ordered from the Parts Marketing Representative

Ordering supplies