Electrical Installation | Interconnection wiring is required between the motor control, AC power source, motor, | |

| host control and any operator interface stations. Use only UL (cUL) listed closed loop | |

| connectors that are of appropriate size for wire gauge being used. Connectors are to be | |

| installed using crimp tool specified by the manufacturer of the connector. Only Class 1 | |

| wiring should be used. | |

| Baldor Series 22H controls feature UL approved adjustable motor overload protection | |

| suitable for motors rated at no less than 50% of the output rating of the control. Other | |

| governing agencies such as NEC may require separate | |

| installer of this equipment is responsible for complying with the National Electric Code | |

| and any applicable local codes which govern such practices as wiring protection, | |

| grounding, disconnects and other current protection. | |

Load Reactors | Line reactors may be used at the control output to the motor. When used this way, they are | |

| called Load Reactors. Load reactors serve several functions that include: | |

| S | Protect the control from a short circuit at the motor. |

| S | Limit the rate of rise of motor surge currents. |

| S | Slowing the rate of change of power the control delivers to the motor. |

| Load reactors should be installed as close to the control as possible. Select the load | |

| reactor that matches the full load amperes (FLA) stated on the nameplate of the motor | |

| you are using. | |

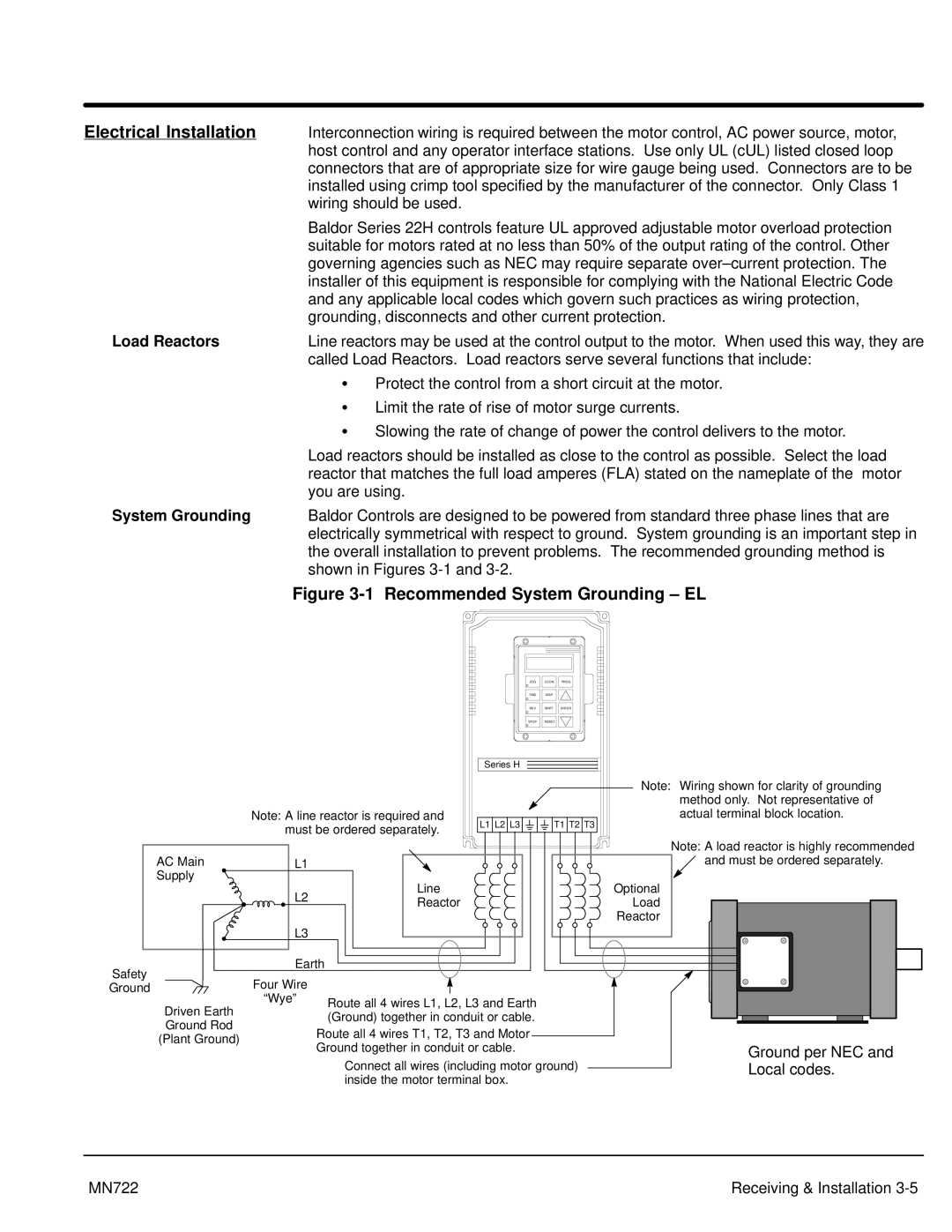

System Grounding | Baldor Controls are designed to be powered from standard three phase lines that are | |

| electrically symmetrical with respect to ground. System grounding is an important step in | |

| the overall installation to prevent problems. The recommended grounding method is | |

| shown in Figures | |

Figure 3-1 Recommended System Grounding – EL

JOG | LOCAL | PROG |

FWD | DISP |

|

REV | SHIFT | ENTER |

STOP | RESET |

|

Series H

|

|

|

|

| Note: Wiring shown for clarity of grounding |

|

|

|

|

| method only. Not representative of |

| Note: A line reactor is required and | L1 L2 L3 | T1 T2 T3 | actual terminal block location. | |

| must be ordered separately. |

| |||

|

|

|

| ||

|

|

|

|

| Note: A load reactor is highly recommended |

AC Main | L1 |

|

|

| and must be ordered separately. |

Supply |

| Line |

|

| Optional |

| L2 |

|

| ||

| Reactor |

|

| Load | |

|

|

|

| ||

|

|

|

|

| Reactor |

| L3 |

|

|

|

|

Safety | Earth |

|

|

| |

Four Wire |

|

|

|

| |

Ground |

|

|

|

| |

Driven Earth | “Wye” | Route all 4 wires L1, L2, L3 and Earth |

|

| |

|

|

| |||

| (Ground) together in conduit or cable. |

|

| ||

Ground Rod |

|

|

| ||

| Route all 4 wires T1, T2, T3 and Motor |

|

| ||

(Plant Ground) |

|

|

| ||

| Ground together in conduit or cable. |

| Ground per NEC and | ||

|

|

| |||

|

| Connect all wires (including motor ground) | Local codes. | ||

|

| inside the motor terminal box. |

|

| |

MN722 | Receiving & Installation |