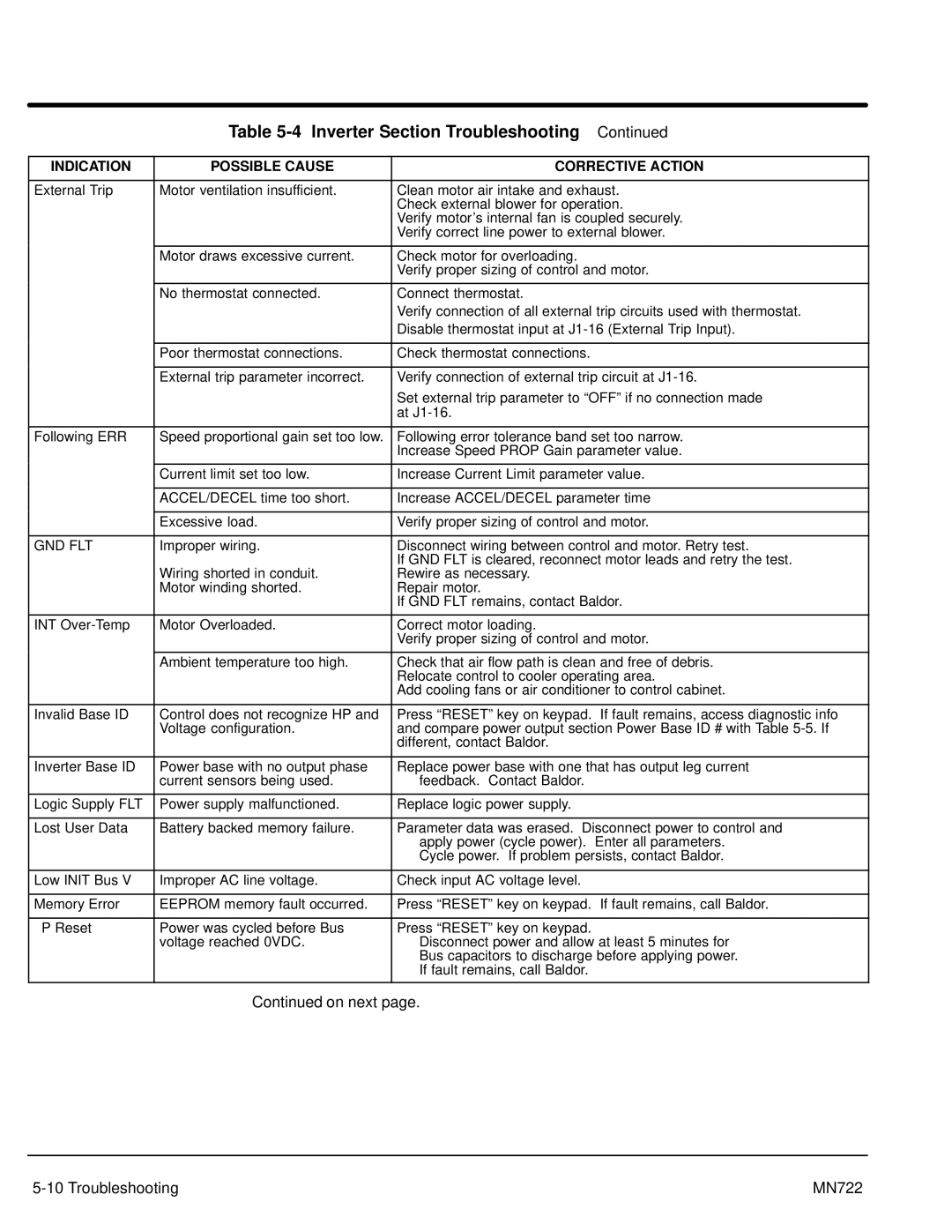

Table 5-4 Inverter Section Troubleshooting Continued

INDICATION | POSSIBLE CAUSE | CORRECTIVE ACTION |

|

|

|

External Trip | Motor ventilation insufficient. | Clean motor air intake and exhaust. |

|

| Check external blower for operation. |

|

| Verify motor’s internal fan is coupled securely. |

|

| Verify correct line power to external blower. |

|

|

|

| Motor draws excessive current. | Check motor for overloading. |

|

| Verify proper sizing of control and motor. |

|

|

|

| No thermostat connected. | Connect thermostat. |

|

| Verify connection of all external trip circuits used with thermostat. |

|

| Disable thermostat input at |

|

|

|

| Poor thermostat connections. | Check thermostat connections. |

|

|

|

| External trip parameter incorrect. | Verify connection of external trip circuit at |

|

| Set external trip parameter to “OFF” if no connection made |

|

| at |

|

|

|

Following ERR | Speed proportional gain set too low. | Following error tolerance band set too narrow. |

|

| Increase Speed PROP Gain parameter value. |

|

|

|

| Current limit set too low. | Increase Current Limit parameter value. |

|

|

|

| ACCEL/DECEL time too short. | Increase ACCEL/DECEL parameter time |

|

|

|

| Excessive load. | Verify proper sizing of control and motor. |

|

|

|

GND FLT | Improper wiring. | Disconnect wiring between control and motor. Retry test. |

|

| If GND FLT is cleared, reconnect motor leads and retry the test. |

| Wiring shorted in conduit. | Rewire as necessary. |

| Motor winding shorted. | Repair motor. |

|

| If GND FLT remains, contact Baldor. |

|

|

|

INT | Motor Overloaded. | Correct motor loading. |

|

| Verify proper sizing of control and motor. |

|

|

|

| Ambient temperature too high. | Check that air flow path is clean and free of debris. |

|

| Relocate control to cooler operating area. |

|

| Add cooling fans or air conditioner to control cabinet. |

|

|

|

Invalid Base ID | Control does not recognize HP and | Press “RESET” key on keypad. If fault remains, access diagnostic info |

| Voltage configuration. | and compare power output section Power Base ID # with Table |

|

| different, contact Baldor. |

|

|

|

Inverter Base ID | Power base with no output phase | Replace power base with one that has output leg current |

| current sensors being used. | feedback. Contact Baldor. |

|

|

|

Logic Supply FLT | Power supply malfunctioned. | Replace logic power supply. |

|

|

|

Lost User Data | Battery backed memory failure. | Parameter data was erased. Disconnect power to control and |

|

| apply power (cycle power). Enter all parameters. |

|

| Cycle power. If problem persists, contact Baldor. |

|

|

|

Low INIT Bus V | Improper AC line voltage. | Check input AC voltage level. |

|

|

|

Memory Error | EEPROM memory fault occurred. | Press “RESET” key on keypad. If fault remains, call Baldor. |

|

|

|

mP Reset | Power was cycled before Bus | Press “RESET” key on keypad. |

| voltage reached 0VDC. | Disconnect power and allow at least 5 minutes for |

|

| Bus capacitors to discharge before applying power. |

|

| If fault remains, call Baldor. |

|

|

|

Continued on next page.

| MN722 |