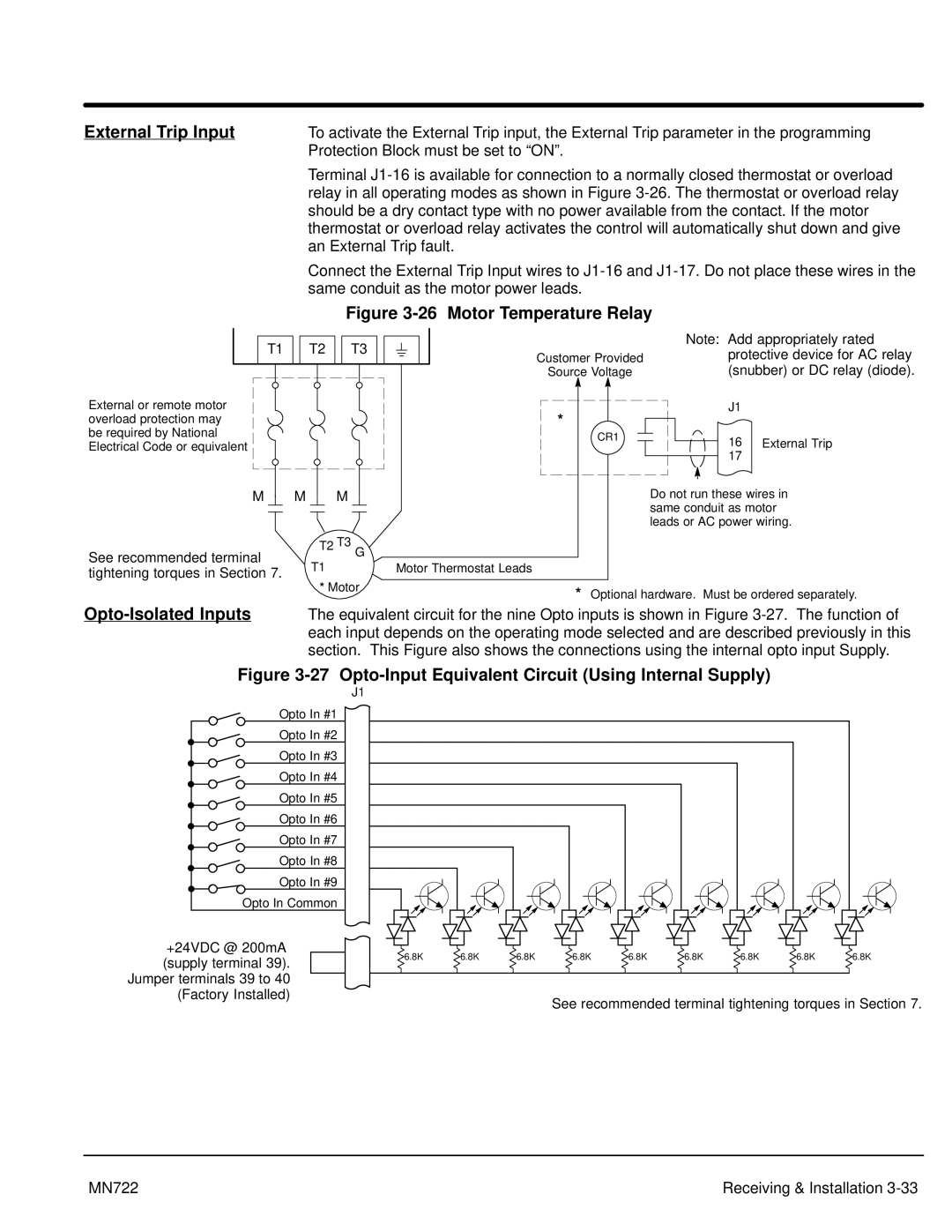

External Trip Input | To activate the External Trip input, the External Trip parameter in the programming |

| Protection Block must be set to “ON”. |

| Terminal |

| relay in all operating modes as shown in Figure |

| should be a dry contact type with no power available from the contact. If the motor |

| thermostat or overload relay activates the control will automatically shut down and give |

| an External Trip fault. |

| Connect the External Trip Input wires to |

| same conduit as the motor power leads. |

| Figure |

T1 | T2 | T3 | |

|

| Customer Provided | |

|

| Source Voltage | |

External or remote motor |

| * | |

overload protection may |

| ||

be required by National |

| CR1 | |

Electrical Code or equivalent |

|

| |

M | M | M | |

| T2 T3 | ||

See recommended terminal |

| G | |

T1 | Motor Thermostat Leads | ||

tightening torques in Section 7. | |||

|

| ||

Note: Add appropriately rated protective device for AC relay (snubber) or DC relay (diode).

J1

16External Trip

Do not run these wires in same conduit as motor leads or AC power wiring.

| * Motor | * Optional hardware. Must be ordered separately. |

|

| |

| The equivalent circuit for the nine Opto inputs is shown in Figure | |

| each input depends on the operating mode selected and are described previously in this | |

| section. This Figure also shows the connections using the internal opto input Supply. | |

Figure 3-27 Opto-Input Equivalent Circuit (Using Internal Supply)

Opto In #1 |

Opto In #2 |

Opto In #3 |

Opto In #4 |

Opto In #5 |

Opto In #6 |

Opto In #7 |

Opto In #8 |

Opto In #9 |

Opto In Common |

+24VDC @ 200mA (supply terminal 39).

Jumper terminals 39 to 40 (Factory Installed)

J1 |

|

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

13 |

|

|

|

|

|

|

|

|

|

14 |

|

|

|

|

|

|

|

|

|

15 |

|

|

|

|

|

|

|

|

|

16 |

|

|

|

|

|

|

|

|

|

17 |

|

|

|

|

|

|

|

|

|

39 | 6.8K | 6.8K | 6.8K | 6.8K | 6.8K | 6.8K | 6.8K | 6.8K | 6.8K |

| |||||||||

40 |

|

|

|

|

|

|

|

|

|

See recommended terminal tightening torques in Section 7.

MN722 | Receiving & Installation |