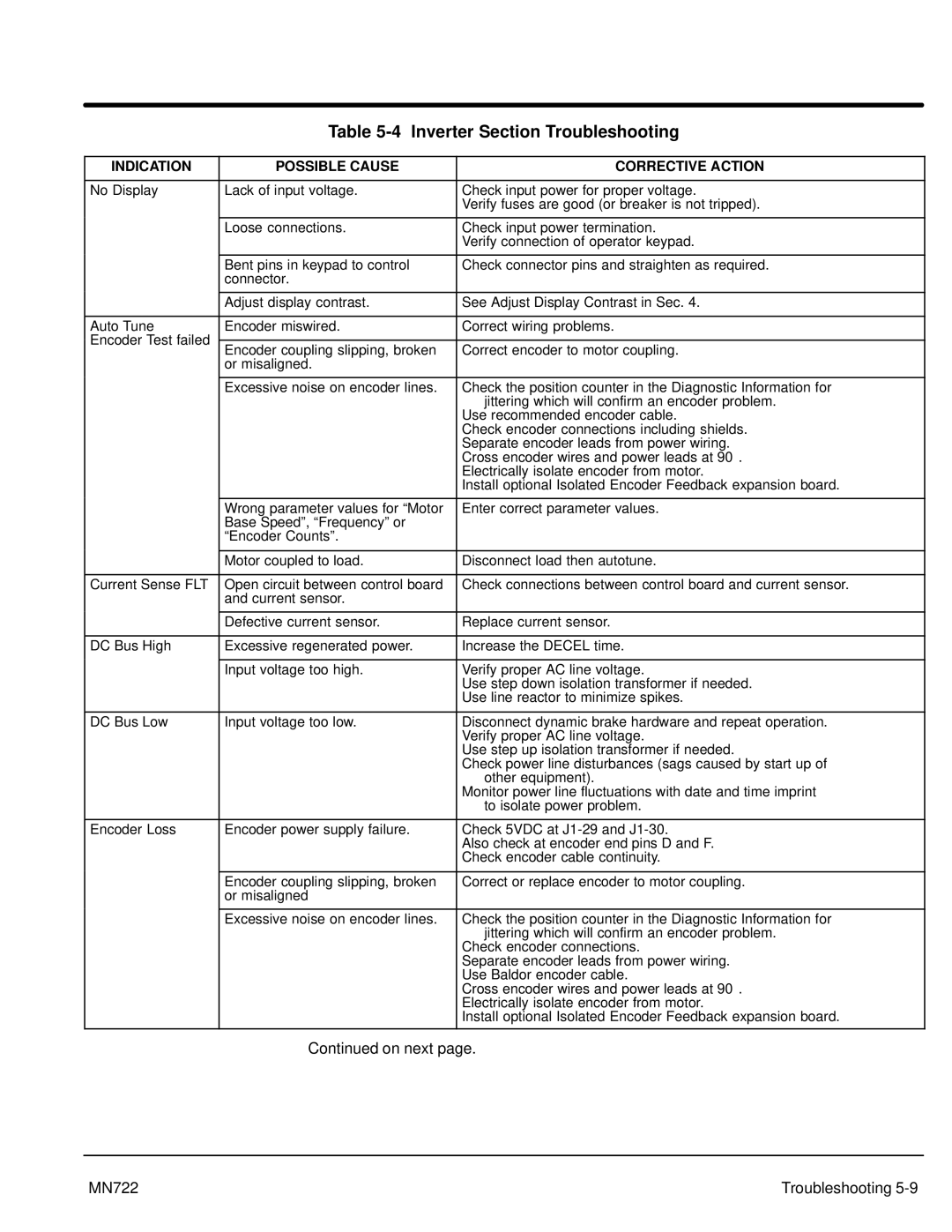

Table 5-4 Inverter Section Troubleshooting

INDICATION | POSSIBLE CAUSE | CORRECTIVE ACTION | |

|

|

| |

No Display | Lack of input voltage. | Check input power for proper voltage. | |

|

| Verify fuses are good (or breaker is not tripped). | |

|

|

| |

| Loose connections. | Check input power termination. | |

|

| Verify connection of operator keypad. | |

|

|

| |

| Bent pins in keypad to control | Check connector pins and straighten as required. | |

| connector. |

| |

|

|

| |

| Adjust display contrast. | See Adjust Display Contrast in Sec. 4. | |

|

|

| |

Auto Tune | Encoder miswired. | Correct wiring problems. | |

Encoder Test failed |

|

| |

Encoder coupling slipping, broken | Correct encoder to motor coupling. | ||

| |||

| or misaligned. |

| |

|

|

| |

| Excessive noise on encoder lines. | Check the position counter in the Diagnostic Information for | |

|

| jittering which will confirm an encoder problem. | |

|

| Use recommended encoder cable. | |

|

| Check encoder connections including shields. | |

|

| Separate encoder leads from power wiring. | |

|

| Cross encoder wires and power leads at 90° . | |

|

| Electrically isolate encoder from motor. | |

|

| Install optional Isolated Encoder Feedback expansion board. | |

|

|

| |

| Wrong parameter values for “Motor | Enter correct parameter values. | |

| Base Speed”, “Frequency” or |

| |

| “Encoder Counts”. |

| |

|

|

| |

| Motor coupled to load. | Disconnect load then autotune. | |

|

|

| |

Current Sense FLT | Open circuit between control board | Check connections between control board and current sensor. | |

| and current sensor. |

| |

|

|

| |

| Defective current sensor. | Replace current sensor. | |

|

|

| |

DC Bus High | Excessive regenerated power. | Increase the DECEL time. | |

|

|

| |

| Input voltage too high. | Verify proper AC line voltage. | |

|

| Use step down isolation transformer if needed. | |

|

| Use line reactor to minimize spikes. | |

|

|

| |

DC Bus Low | Input voltage too low. | Disconnect dynamic brake hardware and repeat operation. | |

|

| Verify proper AC line voltage. | |

|

| Use step up isolation transformer if needed. | |

|

| Check power line disturbances (sags caused by start up of | |

|

| other equipment). | |

|

| Monitor power line fluctuations with date and time imprint | |

|

| to isolate power problem. | |

|

|

| |

Encoder Loss | Encoder power supply failure. | Check 5VDC at | |

|

| Also check at encoder end pins D and F. | |

|

| Check encoder cable continuity. | |

|

|

| |

| Encoder coupling slipping, broken | Correct or replace encoder to motor coupling. | |

| or misaligned |

| |

|

|

| |

| Excessive noise on encoder lines. | Check the position counter in the Diagnostic Information for | |

|

| jittering which will confirm an encoder problem. | |

|

| Check encoder connections. | |

|

| Separate encoder leads from power wiring. | |

|

| Use Baldor encoder cable. | |

|

| Cross encoder wires and power leads at 90° . | |

|

| Electrically isolate encoder from motor. | |

|

| Install optional Isolated Encoder Feedback expansion board. | |

|

|

|

Continued on next page.

MN722 | Troubleshooting |