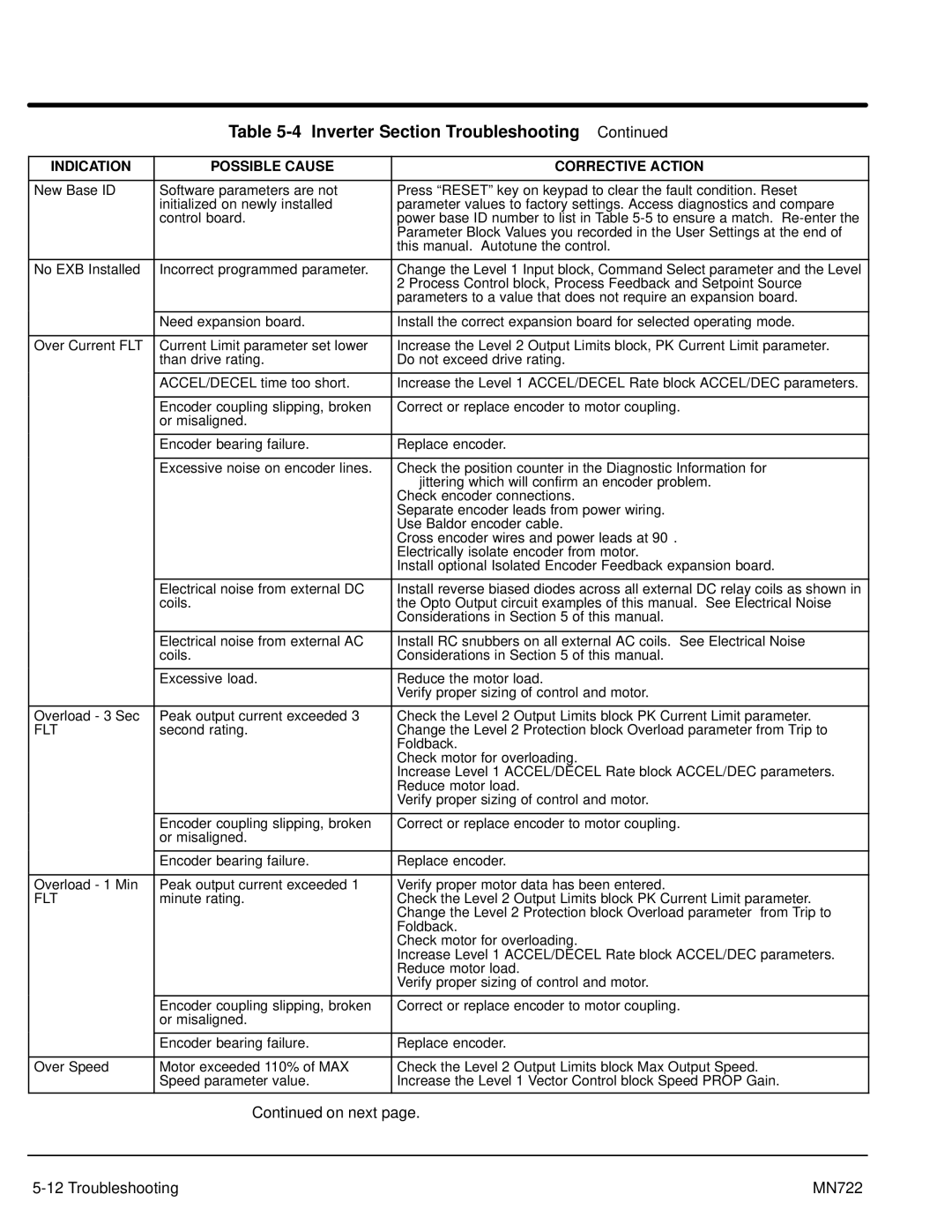

Table 5-4 Inverter Section Troubleshooting Continued

INDICATION | POSSIBLE CAUSE | CORRECTIVE ACTION |

|

|

|

New Base ID | Software parameters are not | Press “RESET” key on keypad to clear the fault condition. Reset |

| initialized on newly installed | parameter values to factory settings. Access diagnostics and compare |

| control board. | power base ID number to list in Table |

|

| Parameter Block Values you recorded in the User Settings at the end of |

|

| this manual. Autotune the control. |

|

|

|

No EXB Installed | Incorrect programmed parameter. | Change the Level 1 Input block, Command Select parameter and the Level |

|

| 2 Process Control block, Process Feedback and Setpoint Source |

|

| parameters to a value that does not require an expansion board. |

|

|

|

| Need expansion board. | Install the correct expansion board for selected operating mode. |

|

|

|

Over Current FLT | Current Limit parameter set lower | Increase the Level 2 Output Limits block, PK Current Limit parameter. |

| than drive rating. | Do not exceed drive rating. |

|

|

|

| ACCEL/DECEL time too short. | Increase the Level 1 ACCEL/DECEL Rate block ACCEL/DEC parameters. |

|

|

|

| Encoder coupling slipping, broken | Correct or replace encoder to motor coupling. |

| or misaligned. |

|

|

|

|

| Encoder bearing failure. | Replace encoder. |

|

|

|

| Excessive noise on encoder lines. | Check the position counter in the Diagnostic Information for |

|

| jittering which will confirm an encoder problem. |

|

| Check encoder connections. |

|

| Separate encoder leads from power wiring. |

|

| Use Baldor encoder cable. |

|

| Cross encoder wires and power leads at 90° . |

|

| Electrically isolate encoder from motor. |

|

| Install optional Isolated Encoder Feedback expansion board. |

|

|

|

| Electrical noise from external DC | Install reverse biased diodes across all external DC relay coils as shown in |

| coils. | the Opto Output circuit examples of this manual. See Electrical Noise |

|

| Considerations in Section 5 of this manual. |

|

|

|

| Electrical noise from external AC | Install RC snubbers on all external AC coils. See Electrical Noise |

| coils. | Considerations in Section 5 of this manual. |

|

|

|

| Excessive load. | Reduce the motor load. |

|

| Verify proper sizing of control and motor. |

|

|

|

Overload - 3 Sec | Peak output current exceeded 3 | Check the Level 2 Output Limits block PK Current Limit parameter. |

FLT | second rating. | Change the Level 2 Protection block Overload parameter from Trip to |

|

| Foldback. |

|

| Check motor for overloading. |

|

| Increase Level 1 ACCEL/DECEL Rate block ACCEL/DEC parameters. |

|

| Reduce motor load. |

|

| Verify proper sizing of control and motor. |

|

|

|

| Encoder coupling slipping, broken | Correct or replace encoder to motor coupling. |

| or misaligned. |

|

|

|

|

| Encoder bearing failure. | Replace encoder. |

|

|

|

Overload - 1 Min | Peak output current exceeded 1 | Verify proper motor data has been entered. |

FLT | minute rating. | Check the Level 2 Output Limits block PK Current Limit parameter. |

|

| Change the Level 2 Protection block Overload parameter from Trip to |

|

| Foldback. |

|

| Check motor for overloading. |

|

| Increase Level 1 ACCEL/DECEL Rate block ACCEL/DEC parameters. |

|

| Reduce motor load. |

|

| Verify proper sizing of control and motor. |

|

|

|

| Encoder coupling slipping, broken | Correct or replace encoder to motor coupling. |

| or misaligned. |

|

|

|

|

| Encoder bearing failure. | Replace encoder. |

|

|

|

Over Speed | Motor exceeded 110% of MAX | Check the Level 2 Output Limits block Max Output Speed. |

| Speed parameter value. | Increase the Level 1 Vector Control block Speed PROP Gain. |

|

|

|

| Continued on next page. | |

|

|

|

| MN722 | |