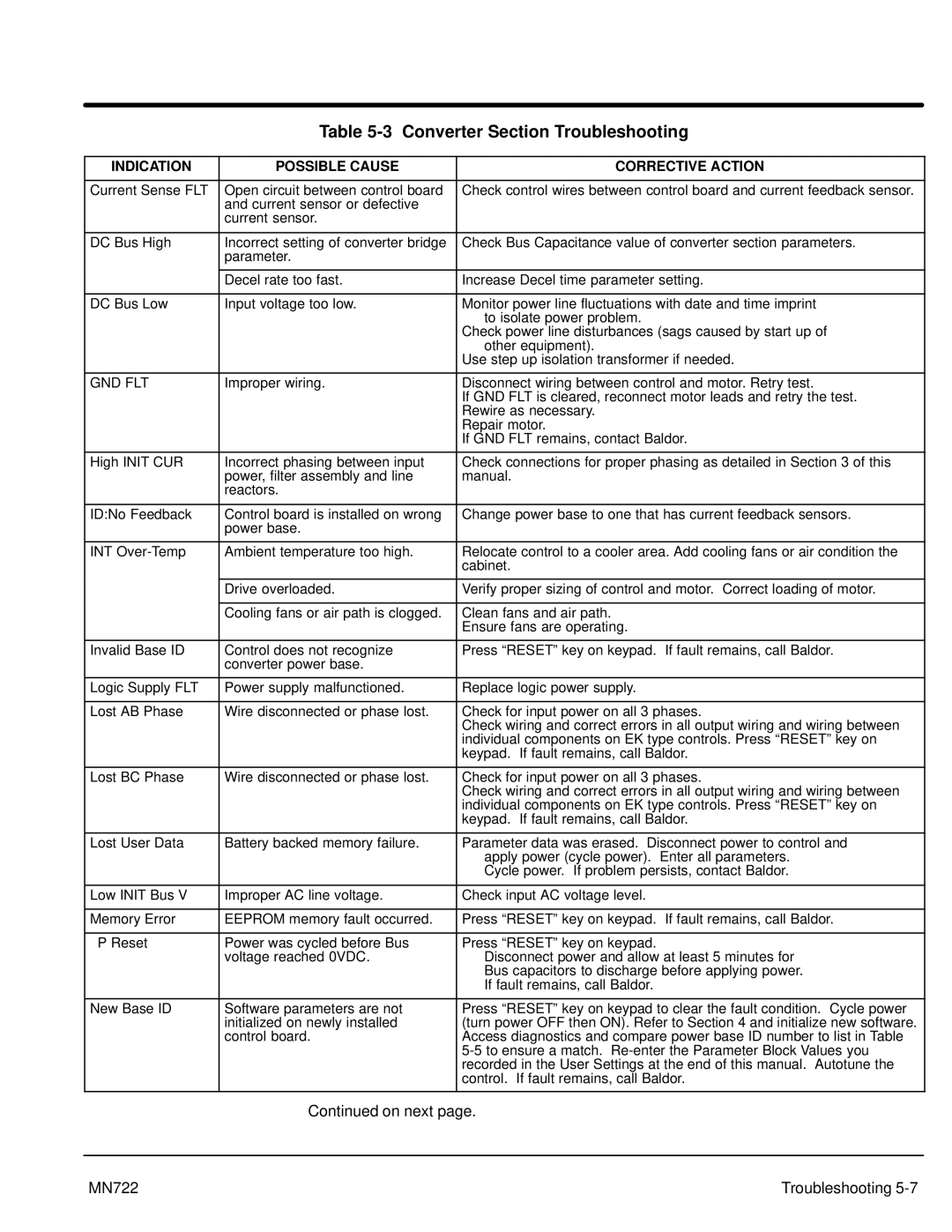

Table 5-3 Converter Section Troubleshooting

INDICATION | POSSIBLE CAUSE | CORRECTIVE ACTION |

|

|

|

Current Sense FLT | Open circuit between control board | Check control wires between control board and current feedback sensor. |

| and current sensor or defective |

|

| current sensor. |

|

|

|

|

DC Bus High | Incorrect setting of converter bridge | Check Bus Capacitance value of converter section parameters. |

| parameter. |

|

|

|

|

| Decel rate too fast. | Increase Decel time parameter setting. |

|

|

|

DC Bus Low | Input voltage too low. | Monitor power line fluctuations with date and time imprint |

|

| to isolate power problem. |

|

| Check power line disturbances (sags caused by start up of |

|

| other equipment). |

|

| Use step up isolation transformer if needed. |

|

|

|

GND FLT | Improper wiring. | Disconnect wiring between control and motor. Retry test. |

|

| If GND FLT is cleared, reconnect motor leads and retry the test. |

|

| Rewire as necessary. |

|

| Repair motor. |

|

| If GND FLT remains, contact Baldor. |

|

|

|

High INIT CUR | Incorrect phasing between input | Check connections for proper phasing as detailed in Section 3 of this |

| power, filter assembly and line | manual. |

| reactors. |

|

|

|

|

ID:No Feedback | Control board is installed on wrong | Change power base to one that has current feedback sensors. |

| power base. |

|

|

|

|

INT | Ambient temperature too high. | Relocate control to a cooler area. Add cooling fans or air condition the |

|

| cabinet. |

|

|

|

| Drive overloaded. | Verify proper sizing of control and motor. Correct loading of motor. |

|

|

|

| Cooling fans or air path is clogged. | Clean fans and air path. |

|

| Ensure fans are operating. |

|

|

|

Invalid Base ID | Control does not recognize | Press “RESET” key on keypad. If fault remains, call Baldor. |

| converter power base. |

|

|

|

|

Logic Supply FLT | Power supply malfunctioned. | Replace logic power supply. |

|

|

|

Lost AB Phase | Wire disconnected or phase lost. | Check for input power on all 3 phases. |

|

| Check wiring and correct errors in all output wiring and wiring between |

|

| individual components on EK type controls. Press “RESET” key on |

|

| keypad. If fault remains, call Baldor. |

|

|

|

Lost BC Phase | Wire disconnected or phase lost. | Check for input power on all 3 phases. |

|

| Check wiring and correct errors in all output wiring and wiring between |

|

| individual components on EK type controls. Press “RESET” key on |

|

| keypad. If fault remains, call Baldor. |

|

|

|

Lost User Data | Battery backed memory failure. | Parameter data was erased. Disconnect power to control and |

|

| apply power (cycle power). Enter all parameters. |

|

| Cycle power. If problem persists, contact Baldor. |

|

|

|

Low INIT Bus V | Improper AC line voltage. | Check input AC voltage level. |

|

|

|

Memory Error | EEPROM memory fault occurred. | Press “RESET” key on keypad. If fault remains, call Baldor. |

|

|

|

mP Reset | Power was cycled before Bus | Press “RESET” key on keypad. |

| voltage reached 0VDC. | Disconnect power and allow at least 5 minutes for |

|

| Bus capacitors to discharge before applying power. |

|

| If fault remains, call Baldor. |

|

|

|

New Base ID | Software parameters are not | Press “RESET” key on keypad to clear the fault condition. Cycle power |

| initialized on newly installed | (turn power OFF then ON). Refer to Section 4 and initialize new software. |

| control board. | Access diagnostics and compare power base ID number to list in Table |

|

| |

|

| recorded in the User Settings at the end of this manual. Autotune the |

|

| control. If fault remains, call Baldor. |

|

|

|

| Continued on next page. | |

|

|

|

MN722 |

| Troubleshooting |