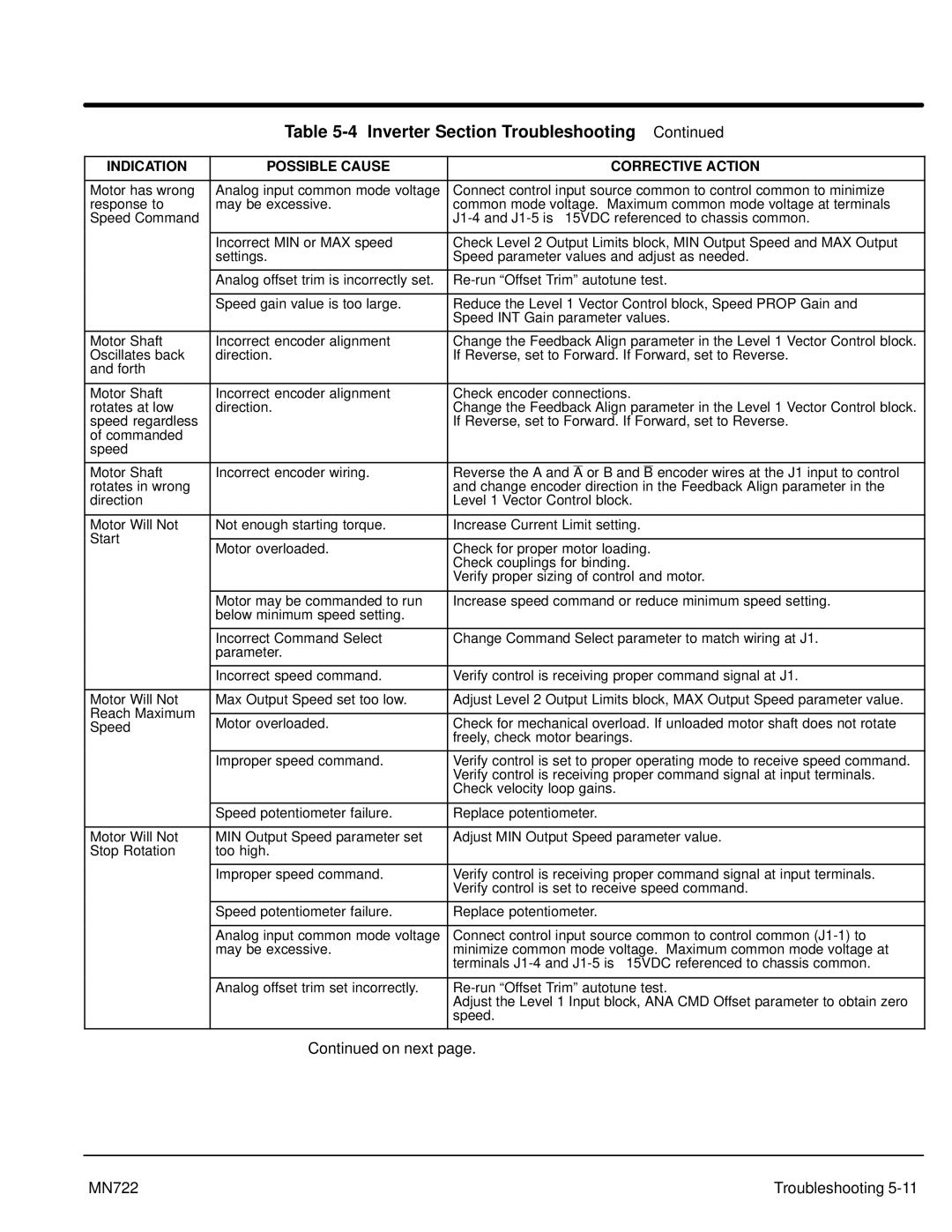

Table 5-4 Inverter Section Troubleshooting Continued

INDICATION | POSSIBLE CAUSE |

|

| CORRECTIVE ACTION | |||

|

|

|

|

|

|

| |

Motor has wrong | Analog input common mode voltage | Connect control input source common to control common to minimize | |||||

response to | may be excessive. | common mode voltage. Maximum common mode voltage at terminals | |||||

Speed Command |

| ||||||

|

|

|

|

|

|

| |

| Incorrect MIN or MAX speed | Check Level 2 Output Limits block, MIN Output Speed and MAX Output | |||||

| settings. | Speed parameter values and adjust as needed. | |||||

|

|

|

|

|

|

| |

| Analog offset trim is incorrectly set. | ||||||

|

|

|

|

|

|

| |

| Speed gain value is too large. | Reduce the Level 1 Vector Control block, Speed PROP Gain and | |||||

|

| Speed INT Gain parameter values. | |||||

|

|

|

|

|

|

| |

Motor Shaft | Incorrect encoder alignment | Change the Feedback Align parameter in the Level 1 Vector Control block. | |||||

Oscillates back | direction. | If Reverse, set to Forward. If Forward, set to Reverse. | |||||

and forth |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Motor Shaft | Incorrect encoder alignment | Check encoder connections. | |||||

rotates at low | direction. | Change the Feedback Align parameter in the Level 1 Vector Control block. | |||||

speed regardless |

| If Reverse, set to Forward. If Forward, set to Reverse. | |||||

of commanded |

|

|

|

|

|

| |

speed |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Motor Shaft | Incorrect encoder wiring. | Reverse the A and |

| or B and |

| encoder wires at the J1 input to control | |

A | B | ||||||

rotates in wrong |

| and change encoder direction in the Feedback Align parameter in the | |||||

direction |

| Level 1 Vector Control block. | |||||

|

|

| |||||

Motor Will Not | Not enough starting torque. | Increase Current Limit setting. | |||||

Start |

|

|

|

|

|

| |

Motor overloaded. | Check for proper motor loading. | ||||||

| |||||||

|

| Check couplings for binding. | |||||

|

| Verify proper sizing of control and motor. | |||||

|

|

| |||||

| Motor may be commanded to run | Increase speed command or reduce minimum speed setting. | |||||

| below minimum speed setting. |

|

|

|

|

| |

|

|

| |||||

| Incorrect Command Select | Change Command Select parameter to match wiring at J1. | |||||

| parameter. |

|

|

|

|

| |

|

|

| |||||

| Incorrect speed command. | Verify control is receiving proper command signal at J1. | |||||

|

|

| |||||

Motor Will Not | Max Output Speed set too low. | Adjust Level 2 Output Limits block, MAX Output Speed parameter value. | |||||

Reach Maximum |

|

|

|

|

|

| |

Motor overloaded. | Check for mechanical overload. If unloaded motor shaft does not rotate | ||||||

Speed | |||||||

|

| freely, check motor bearings. | |||||

|

|

| |||||

| Improper speed command. | Verify control is set to proper operating mode to receive speed command. | |||||

|

| Verify control is receiving proper command signal at input terminals. | |||||

|

| Check velocity loop gains. | |||||

|

|

| |||||

| Speed potentiometer failure. | Replace potentiometer. | |||||

|

|

| |||||

Motor Will Not | MIN Output Speed parameter set | Adjust MIN Output Speed parameter value. | |||||

Stop Rotation | too high. |

|

|

|

|

| |

|

|

| |||||

| Improper speed command. | Verify control is receiving proper command signal at input terminals. | |||||

|

| Verify control is set to receive speed command. | |||||

|

|

| |||||

| Speed potentiometer failure. | Replace potentiometer. | |||||

|

|

| |||||

| Analog input common mode voltage | Connect control input source common to control common | |||||

| may be excessive. | minimize common mode voltage. Maximum common mode voltage at | |||||

|

| terminals | |||||

|

|

| |||||

| Analog offset trim set incorrectly. | ||||||

|

| Adjust the Level 1 Input block, ANA CMD Offset parameter to obtain zero | |||||

|

| speed. | |||||

|

|

|

|

|

|

| |

Continued on next page.

MN722 | Troubleshooting |