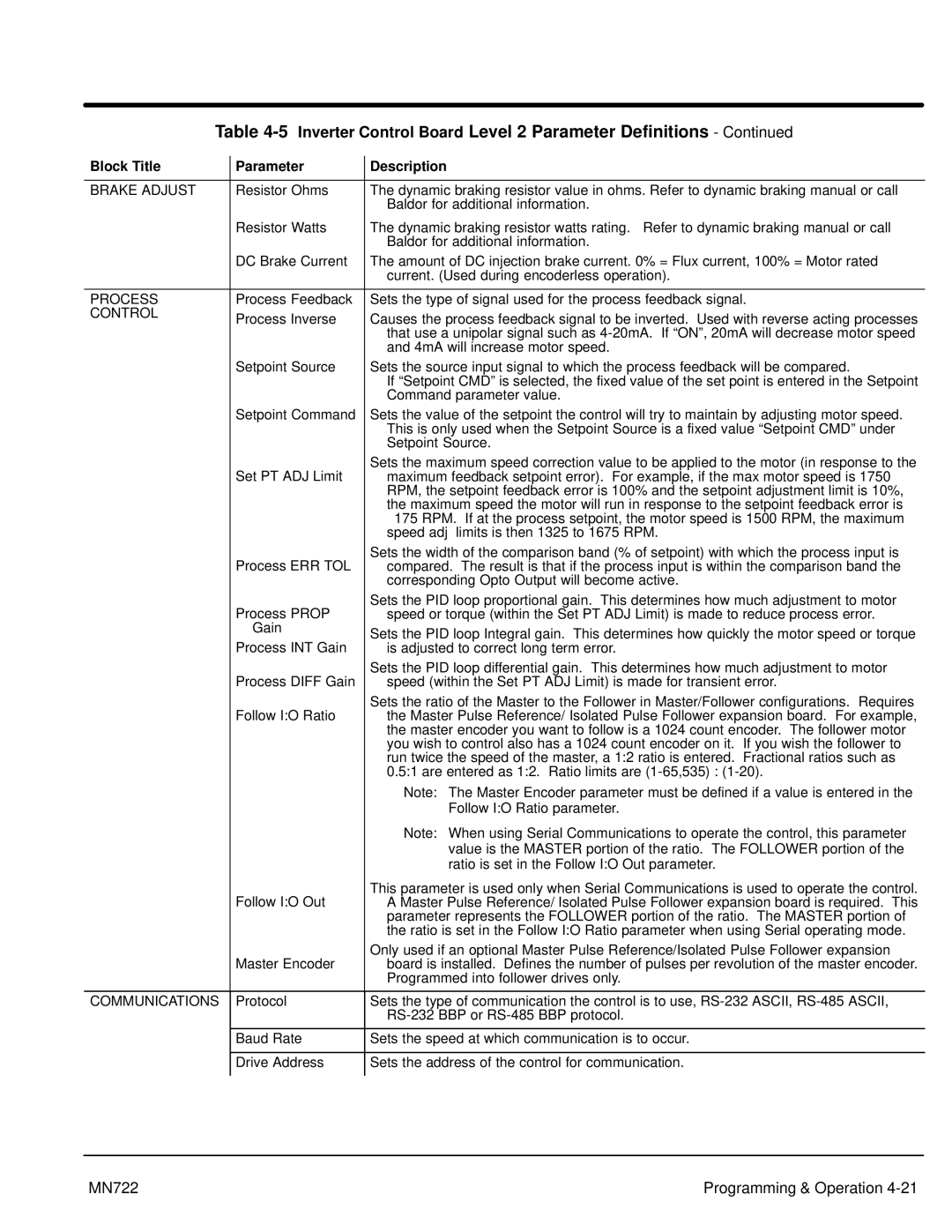

Table 4-5 Inverter Control Board Level 2 Parameter Definitions - Continued

Block Title | Parameter | Description |

|

|

|

BRAKE ADJUST | Resistor Ohms | The dynamic braking resistor value in ohms. Refer to dynamic braking manual or call |

|

| Baldor for additional information. |

| Resistor Watts | The dynamic braking resistor watts rating. Refer to dynamic braking manual or call |

|

| Baldor for additional information. |

| DC Brake Current | The amount of DC injection brake current. 0% = Flux current, 100% = Motor rated |

|

| current. (Used during encoderless operation). |

|

|

|

PROCESS | Process Feedback | Sets the type of signal used for the process feedback signal. |

CONTROL | Process Inverse | Causes the process feedback signal to be inverted. Used with reverse acting processes |

| ||

|

| that use a unipolar signal such as |

|

| and 4mA will increase motor speed. |

| Setpoint Source | Sets the source input signal to which the process feedback will be compared. |

|

| If “Setpoint CMD” is selected, the fixed value of the set point is entered in the Setpoint |

|

| Command parameter value. |

| Setpoint Command | Sets the value of the setpoint the control will try to maintain by adjusting motor speed. |

|

| This is only used when the Setpoint Source is a fixed value “Setpoint CMD” under |

|

| Setpoint Source. |

| Set PT ADJ Limit | Sets the maximum speed correction value to be applied to the motor (in response to the |

| maximum feedback setpoint error). For example, if the max motor speed is 1750 | |

|

| RPM, the setpoint feedback error is 100% and the setpoint adjustment limit is 10%, |

|

| the maximum speed the motor will run in response to the setpoint feedback error is |

|

| ± 175 RPM. If at the process setpoint, the motor speed is 1500 RPM, the maximum |

|

| speed adj limits is then 1325 to 1675 RPM. |

| Process ERR TOL | Sets the width of the comparison band (% of setpoint) with which the process input is |

| compared. The result is that if the process input is within the comparison band the | |

|

| corresponding Opto Output will become active. |

| Process PROP | Sets the PID loop proportional gain. This determines how much adjustment to motor |

| speed or torque (within the Set PT ADJ Limit) is made to reduce process error. | |

| Gain | Sets the PID loop Integral gain. This determines how quickly the motor speed or torque |

| Process INT Gain | |

| is adjusted to correct long term error. | |

| Process DIFF Gain | Sets the PID loop differential gain. This determines how much adjustment to motor |

| speed (within the Set PT ADJ Limit) is made for transient error. | |

| Follow I:O Ratio | Sets the ratio of the Master to the Follower in Master/Follower configurations. Requires |

| the Master Pulse Reference/ Isolated Pulse Follower expansion board. For example, | |

|

| the master encoder you want to follow is a 1024 count encoder. The follower motor |

|

| you wish to control also has a 1024 count encoder on it. If you wish the follower to |

|

| run twice the speed of the master, a 1:2 ratio is entered. Fractional ratios such as |

|

| 0.5:1 are entered as 1:2. Ratio limits are |

|

| Note: The Master Encoder parameter must be defined if a value is entered in the |

|

| Follow I:O Ratio parameter. |

|

| Note: When using Serial Communications to operate the control, this parameter |

|

| value is the MASTER portion of the ratio. The FOLLOWER portion of the |

|

| ratio is set in the Follow I:O Out parameter. |

| Follow I:O Out | This parameter is used only when Serial Communications is used to operate the control. |

| A Master Pulse Reference/ Isolated Pulse Follower expansion board is required. This | |

|

| parameter represents the FOLLOWER portion of the ratio. The MASTER portion of |

|

| the ratio is set in the Follow I:O Ratio parameter when using Serial operating mode. |

| Master Encoder | Only used if an optional Master Pulse Reference/Isolated Pulse Follower expansion |

| board is installed. Defines the number of pulses per revolution of the master encoder. | |

|

| Programmed into follower drives only. |

|

|

|

COMMUNICATIONS

Protocol | Sets the type of communication the control is to use, |

| |

|

|

Baud Rate | Sets the speed at which communication is to occur. |

|

|

Drive Address | Sets the address of the control for communication. |

MN722 | Programming & Operation |