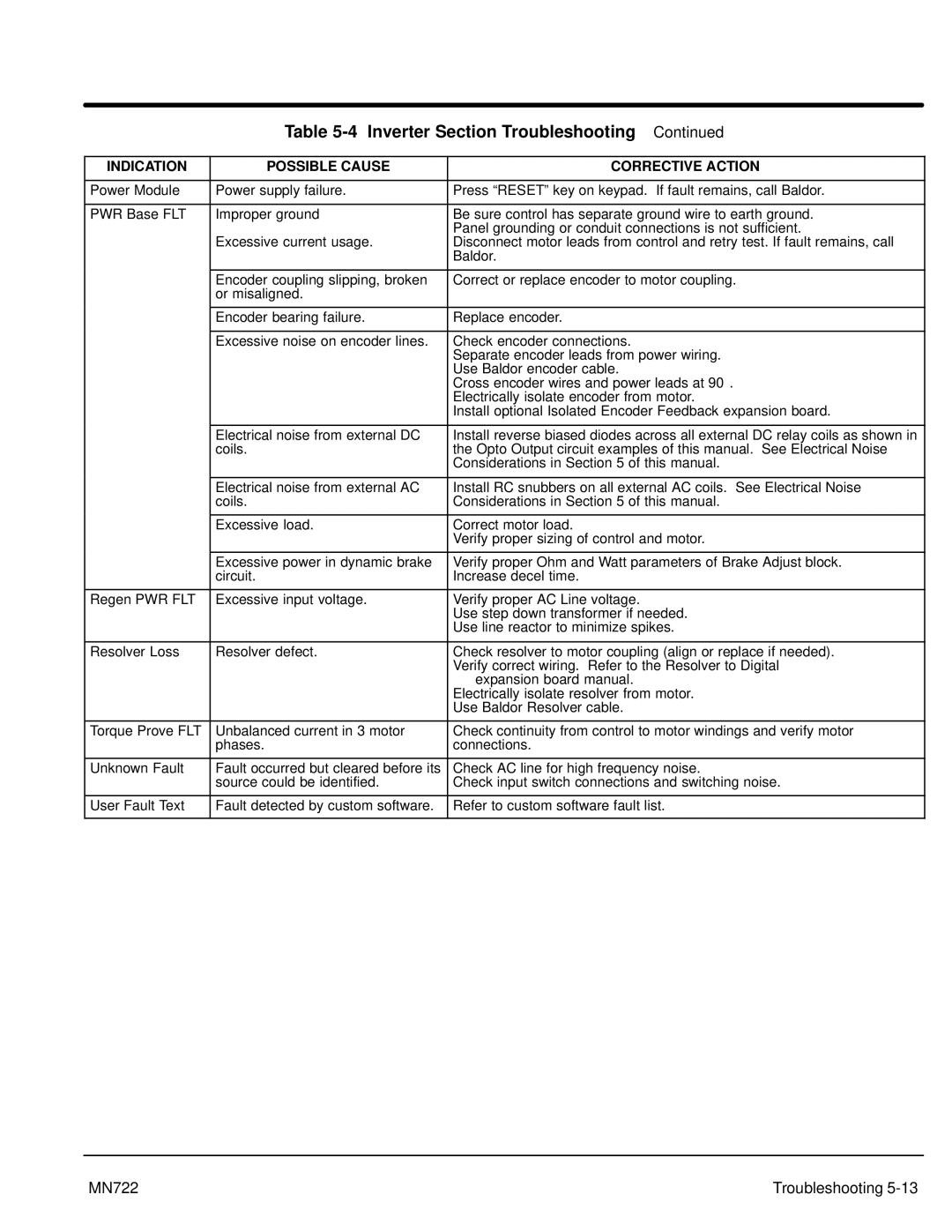

Table 5-4 Inverter Section Troubleshooting Continued

INDICATION | POSSIBLE CAUSE | CORRECTIVE ACTION |

|

|

|

Power Module | Power supply failure. | Press “RESET” key on keypad. If fault remains, call Baldor. |

|

|

|

PWR Base FLT | Improper ground | Be sure control has separate ground wire to earth ground. |

|

| Panel grounding or conduit connections is not sufficient. |

| Excessive current usage. | Disconnect motor leads from control and retry test. If fault remains, call |

|

| Baldor. |

|

|

|

| Encoder coupling slipping, broken | Correct or replace encoder to motor coupling. |

| or misaligned. |

|

|

|

|

| Encoder bearing failure. | Replace encoder. |

|

|

|

| Excessive noise on encoder lines. | Check encoder connections. |

|

| Separate encoder leads from power wiring. |

|

| Use Baldor encoder cable. |

|

| Cross encoder wires and power leads at 90° . |

|

| Electrically isolate encoder from motor. |

|

| Install optional Isolated Encoder Feedback expansion board. |

|

|

|

| Electrical noise from external DC | Install reverse biased diodes across all external DC relay coils as shown in |

| coils. | the Opto Output circuit examples of this manual. See Electrical Noise |

|

| Considerations in Section 5 of this manual. |

|

|

|

| Electrical noise from external AC | Install RC snubbers on all external AC coils. See Electrical Noise |

| coils. | Considerations in Section 5 of this manual. |

|

|

|

| Excessive load. | Correct motor load. |

|

| Verify proper sizing of control and motor. |

|

|

|

| Excessive power in dynamic brake | Verify proper Ohm and Watt parameters of Brake Adjust block. |

| circuit. | Increase decel time. |

|

|

|

Regen PWR FLT | Excessive input voltage. | Verify proper AC Line voltage. |

|

| Use step down transformer if needed. |

|

| Use line reactor to minimize spikes. |

|

|

|

Resolver Loss | Resolver defect. | Check resolver to motor coupling (align or replace if needed). |

|

| Verify correct wiring. Refer to the Resolver to Digital |

|

| expansion board manual. |

|

| Electrically isolate resolver from motor. |

|

| Use Baldor Resolver cable. |

|

|

|

Torque Prove FLT | Unbalanced current in 3 motor | Check continuity from control to motor windings and verify motor |

| phases. | connections. |

|

|

|

Unknown Fault | Fault occurred but cleared before its | Check AC line for high frequency noise. |

| source could be identified. | Check input switch connections and switching noise. |

|

|

|

User Fault Text | Fault detected by custom software. | Refer to custom software fault list. |

|

|

|

MN722 | Troubleshooting |