Robot

Page

Robot models covered by this manual

Preface

Interface Manual this book

How the documentation set is organized

How this book is organized

Describes I/O cables and wiring Iii

Page

Safety Precautions

Sufficient service space is maintained for safe teaching

Should not be installed in any environment where

Structure. Therefore, when using the robot controller in an

Robot and peripheral equipment should be installed so that

Safety Precautions

Page

Refer to the Installation & Maintenance Guide

No robot modification allowed Cleaning of tools Lighting

Signaling methods to be used when more than one worker

Or maintenance inspections, set working regulations for

Operating procedures required to run the robot

Robot speed when performing teaching

Safety Precautions

Page

Management of floppy disks

Page

Contents

Dedicated to Standard Mode

100

Index

Coding of Controller Model Name

Controller Model Name on Nameplate

Position Code Denotes Coding Sample

Deadman switches are located as shown below

How to identify your robot system as Type a

Symbol denoting Type a

External Auto Limited Mode

Internal Auto Limited Mode

Setting the parameter

Names of Robot Controller Components VM-D/HM-E series

Names of the Robot Controller Components

Front

Left side Right side

For robot series except VM-D/HM-E

Connector Marking Name

Table below lists the robot controller specifications

Robot Controller Specifications

Robot Controller Specifications

Page

Outer dimensions of the robot controller are shown below

Outer Dimensions

Series Location Models

Location of IPM boards

Internal Circuits of the Controller Typical configuration

Controller System Configuration

Robot System Configuration

Typical Robot System Configurations

System Configuration Example

Switching between Modes

Standard Mode and Compatible Mode

Auxiliary Functions I/O window appears as shown below

I/O Monitor window appears

Screen returns to the Auxiliary Functions I/O window

I/O assignment mode is switched

Choose allocation window appears as shown below

Following system message appears

Click on the DIO Manager button in the System Manager

Computer

Section

GUIDE, , Section

Options window will appear as shown below

Hardware settings will appear

Connect button appears in a pressed state

Options window closes

Transfer Environment Table window appears

Update the data

I/O assignment mode is switched

Standard Mode

Types and General Information about I/O Signals

Compatibility with conventional VS series robots

Compatible Mode

Controlled by user program Type No. Function Points

2 I/O Type Global Variables

Using User I/O Signals common to both modes

User Input Commands

1 I/O Type Variable Declaration

SET Command

User Output Commands

Types and Functions of System Output Signals Standard Mode

System I/O Signals Standard Mode

Robot Initialization Complete Output

Usage of System Output Signals Standard Mode

OFF conditions

Auto Mode Output

Auto mode Output

On condition

Terminal number

External Mode Output

No.7 of connector CN10

External Mode Output

Servo on Output

No.4 of connector CN10

Servo on Output

Robot-in-operation Output

Signal will be turned OFF with Stop ALL Programs

Normal CPU Output

Normal CPU Output

Robot Failure Output

Robot Failure Output

Robot Warning Output

Robot Warning Output

Dead Battery Warning Output

Dead Battery Warning Output

This signal comes on when the SS mode is selected

SS mode Output

Continue Start Permitted Output

Emergency Stop Output from a contact

No of connector CN10 Emergency stop +

Contact

Types and Functions of System Input Signals Standard Mode

Relationship Between Enable Auto Input and Selectable Mode

Usage of System Input Signals Standard Mode

Enable Auto Input

No of connector CN8

Timing of the input

Robot Stop Input

Terminal

No.5 of connector CN8

Step Stop Signal

Step Stop All Tasks Input

Minimum Instantaneous Stop Pulse Width

Instantaneous Stop All Tasks Input

Input Conditions and Operation of Interrupt Skip

Terminal number No.9 of connector CN8

Interrupt Skip Input

See the Programmers Manual I, , 12.3 Interrupt ON/OFF

Wrong

Example of Operation When an Interrupt Skip is Input

Table below shows the I/O commands functions

General Information about Commands

Command Functions

Outline of I/O Command Processing

Commands to be executed are processed as shown below

Page

Terminal numbers

Using Each Signal Line

Strobe Signal Input

No of connector CN10

Command Processing Complete Output

Status Area

Nos to 32 of connector CN10

Table below lists I/O commands

3 I/O Commands Details List of I/O Commands

List of I/O Commands

Format

Program Operation Command

Description

Page

Page

External Speed and Acceleration Setting

Refer to the figure given below

Error Read

Example of Error Number Output

Hexadecimal codes

Type I Variable Write

Type I Variable Read

Mode Switching

Page

Clear Robot Failure

This command clears a robot failure that has been caused

3.9 I/O Write

3.10 I/O Read

Equipment setup example

Example of Using System I/O Signals in Standard Mode

Example of Equipment Setup Using a Robot

Start and stop procedure, and system I/O signals

Outline of procedure

On following

Start and Stop Procedure and System I/O Signals-1

END

From preceding

System I/O Signals Compatible Mode

Robot Power on Complete

Usage of System Output Signals in the Compatible Mode

Teach Check

⋅ MOTORu OFv F

CAL Complete Output

Signal outputs to the external device that CAL is completed

CAL Complete Output

External Mode Output

Teaching Output

Teaching Output

Program Start Reset Output on Condition

Program Start Reset Output

Program will be turned OFF with Stop ALL Programs

Single-Cycle End Output

Single-Cycle End Output

Normal CPU Output

Operated. Cancelu ƒv L ‘ € ì

Robot Warning Output

Power on

Clear conditions

Error No. Output

No.17 to No.28 of connector CN10

Signal will be output when an error occurs

Continue Start Permitted Output

Emergency Stop Output from a contact

Types and Functions of System Input Signals Compatible Mode

OFF

Usage of System Input Signals in Compatible Mode

Operation Preparation Start Input

Motor power on input

Example of Operation Preparation Start Signal Timing Chart

Program No. Select Signal

No.11 to No.18 of connector CN8

Program No. Select Input

Example of Program No. Select Signal Sequence Circuit

Example of Program No. Select Signals

Program Start Operation-1

Program Start Input

Program Start Operation-2

Program Start Operation-3

Example of Program Start Signal Rise Timing

Example of program start signal rise on and fall OFF timing

Example of Program Start Signal Fall Timing-2

Example of Program Start Signal Fall Timing-1

Program Start Signal Rise Output Signal Timing

Input Conditions and Operation of Program Reset Signal

Program Reset Input

When issued with the Operation Preparation Start

Input timing

101

102

103

Clear Robot Failure Input

104

Refer to the Programmers Manual I

Continue Start Input

Example of Operation When an Interrupt Skip Signal is Input

106

Example of Using System I/O Signals in Compatible Mode

Start and stop procedure and system I/O signals

On the next 108

109

Signal

Operation Preparation Start Input

Connector Pin Assignment Common to Both Modes NPN type

Connector Pin Assignment NPN type

110

CN1 Pin Assignment Terminal No Name

111

Output CN10 User-/System-output connector standard mode

Connector Pin Assignment in Standard Mode

112

113

Input CN8 User-/System-input connector standard mode

Output CN10 User-/System-output connector compatible mode

Connector Pin Assignment in Compatible Mode

114

115

Input CN8 User-/System-input connector compatible mode

User-Input, System-Input and Hand-Input Circuits NPN type

Robot Controller I/O Circuits NPN type

116

117

118

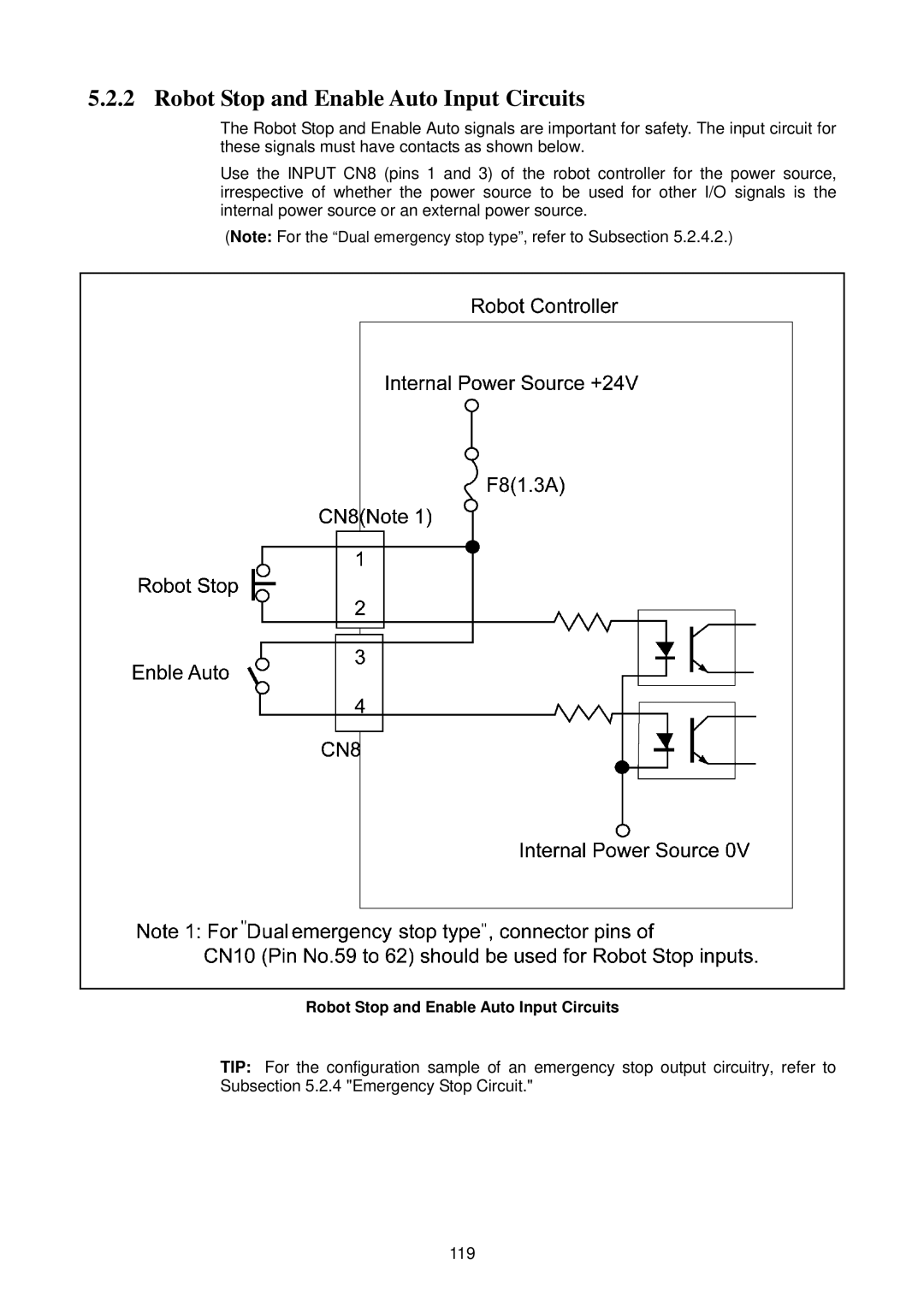

Robot Stop and Enable Auto Input Circuits

Robot Stop and Enable Auto Input Circuits

120

121

122

Example of Circuit with Lamp NPN type

123

124

When the internal power source is used

Emergency Stop Circuit

Standard type

125

Dual emergency stop type

Emergency Stop Circuit Dual emergency stop type

126

5 I/O Power Connector NPN type

127

128

Wiring Notes for Robot Controller I/O Connectors NPN Type

Checking Example

Name Meaning Check Number Point

129

Connector Pin Assignment Common to Both Modes PNP type

Connector Pin Assignment PNP type

130

131

O Power CN7 Power connector for I/O common to both modes

132

Terminal Number Name Port Wire Color Port Wire number color

133

Input CN8 User-/System-input connector standard mode

134

#26, #2 and #27,…#25 and #50

135

User-Input, System-Input and Hand-Input Circuits PNP type

Robot Controller I/O Circuits PNP type

136

137

138

Robot Stop and Enable Auto Input Circuits

140

141

142

Example of Circuit with Lamp PNP type

143

144

145

146

5 I/O Power Connector PNP type

147

148

Wiring Notes for Robot Controller I/O Connectors PNP Type

149

150

Multi-core Cables with Connectors

Cables Optional items

151

Modifying the Shielding Wire Example

Robot Controller Power Supply Specifications

Wiring of Primary Power Source

Index

Servo on Output

Second Edition June

First Edition