Technical Product Manual DCT1900 System

LZB 119 2663 R8

Who should use this manual

Where to find what

Preface

What this manual describes

VII

Section

Safety and Regulatory Information

Technical Product Manual DCT1900

Table of Contents

Safety-DCT1900/R8/mw

General

Safety

Safety-DCT1900/R8/mw

Radio Equipment Handsets and Base Stations

Standards and Regulations

Technical Product Manual DCT1900

Technical Product Manual DCT1900

Technical Product Manual DCT1900

ESD Handling

Protection against Electrostatic Discharge ESD

Protect ESD Sensitive Devices

System Description

Technical Product Manual DCT1900

Radio Exchange Boards

Introduction

System Overview

Hardware Building Blocks

Other System Aspects

Introduction

Technical Product Manual DCT1900

System Overview

Digital Phone Set Features

DCT1900 Network Signalling Summary

System Overview DCT1900 Standalone Environment

System Overview DCT1900 Mobility Environment

Functional External Dependencies

Operational Concepts

Operational Environment

Environmental External Dependencies

Synchronization Topology

System Architecture

Registration Failures

Registration

Start of Registration

Registration Successful

De-registration

Authentication

Inter System Handover DCT1900 Mobility Configuration Only

Roaming DCT1900 Mobility Configuration Only

Environment Scanning by the Portable Telephone

Roaming and Handover Handling by the Portable Telephone

Unlocked Situation

Locked Situation

Voluntary Inter System Roaming

System Status

Roaming

Voluntary Intra System Roaming

User Functions

Standalone Digital Line Interface

Standalone Analog Interface and T1 CAS Digital Interface

Technical Product Manual DCT1900

Radio Exchange

Hardware Building Blocks

Portable Telephones

Base Stations

REX-BRD0007 Standalone only

Radio Exchange Boards

SLU

Speech Link Unit SLU REX-BRD0015 or Rofnb 157 16/1

SPU

Speech Processing Unit SPU-S REX-BRD0017 or Rofnb 157 16/3

CLU/CLU-S

DTU-E1 CCS

DTU-E1 -CAS

CAS REX-BRD0002 or 2/ROFNB 157 13/1

DTU-T1 CAS

DTU-T1 CCS

LTU

DLU

Digital Line Unit DLU REX-BRD0023 Basic Board

Modular Cabinet Connection Board-MCCB Roanb 101

Radio

Traffic Limitations of the System

Installation and Maintenance

Other System Aspects

Statistics

Characteristics

Modular Cabinet number option Cabinet with CPU board

Numbering Conventions

Base Station Numbering

Product Specifications

Technical Product Manual DCT1900

Chargers

Batteries

System Boards

Cabinets

Cables

Power Supply Units

Accessories-Portable Telephone

Firmware on Eprom

Technical Product Manual DCT1900

DT600 Portable Telephone KRC 101 1372 no antenna, Darla Dis

Portable Telephones

Ringer Output

DT620 Portable Telephone KRC 101 1374 no antenna, Dixie Dis

User Interface

9p23 Portable Telephone Messenger 9p23-AAB4

9p23 Programmer Set

9p23 Portable Telephone Medic 9p23-BAB4

9p23 Portable Telephone Mark II Medic 9p23-DAB4

9p23 Portable Telephone Mark II Messenger 9p23-CAB4

Base Station KRC 101

Base Stations

Maximum Cable Length feet

Base Station Cable

Tolerances

Straight Antenna KRE 101 1733/55

Right Angle Antenna KRE 101 1750/55

Adapter Mounting Plate Kit NTM 201

Mounting Kits Outdoor/Wall Mounting Kit NTM 201

Indoor/Ceiling Mounting Kit NTM 201

Batteries for the DT600 High Capacity NiMH BKB 193

Vibrating Battery, NiMH BKB 191

Batteries

Ultra-Slim Line NiMH Battery BKB 193 105/75

Medic Battery

Batteries for the 9p23 Messenger Battery

Messenger Battery with headset connection

Medic Battery with headset connection

Chargers for the DT600 Desk Multi-Charger Kit NTM 201

Rapid Battery Charger Kit BML 162 1016/72 Dis

Chargers

Chargers for the DT620 Rapid Charger BML 162

Rapid Desk Charger BML 162

Rack Charger Kit NTM 201

Docking Station DPY 901

Desktop Charging Cradle BML 162 112/04

3 9p23 Non-Modular Rack Charger AWS1068

4 9p23 Modular Rack Charger US Power Module

Chargers for the 9p23 1 9p23 Messenger Desktop Charger

2 9p23 Medic Desktop Charger

5 9p23 Modular Rack Charger 4 Slot Charging Module RC23

Technical Product Manual DCT1900

Modular Cabinet Connection Board, Mccb Roanb 101

Cabinets

Modular Cabinet Backplane Roanb 101

SDB

Installation Set Sync Port CPU

System Boards

Digital Trunk Specification

Environment

Central Processing Unit CPU2-REX-BRD9033, REX-BRD9034

Sync

Speech Link Unit, SLU REX-BRD0015 or Rofnb 157 16/1

Cell Link Unit, CLU REX-BRD0014 or Rofnb 157 11/2

Fusing

Transport Data Rate 384 kbit/s General Specifications

Speech Processing Unit, SPU-S REX-BRD0017 or Rofnb 157 16/3

Cell Link Unit, CLU-S REX-BRD0016 or Rofnb 157 16/2

Line Termination Unit, LTU REX-BRD0007 or Rofnb 157 02/06

Line Termination Unit , LTU2 REX-BRD0019A

Standard 712 Method Kbit/s A-law or μ−law PCM‘

Digital Line Specification

Firmware on Eprom

13 LTU2 Firmware REX-LTU2FW01/1H

LTU Firmware REX-SW0012 or RYS 105

Power Supply Units

Technical Product Manual DCT1900

Cables for Modular Cabinet

Cables

Pabx Cable E1 Tsrnb 101

DTU-T1/MDF Twisted Pair Cable Trsnb 101 50 AWS1034

LTU/MDF Cable Set NTM/TSRNB 101

DLU/PBX Cable Set AWS1019

DLU Programming Cable AWS1027

DT620 Portable Telephone Programming Cable KRY 101 1135/10

Technical Product Manual DCT1900

Csmw Software Kit, Utam REX-MTC9023

Feature and Phonebook Download Tool AWS1092

Minimum PC configuration

Software

Site Survey Tool Configuration Manager LZY 213

Accessories for the DT600

Accessories-Portable Telephone

Accessories for the DT620

Headsets and Adapters

Accessories for the 9p23

11-4

Configuration Directions

Technical Product Manual DCT1900

Traffic Capacity of the System

Base Station Powering

Limitations of the System

Base Station Planning

Technical Product Manual DCT1900

Configuration Directions, Introduction

Technical Product Manual DCT1900

Modular Cabinets

Limitations of the System

Synchronization Topology

A r d T y p e + 1 2

Modular Cabinet Powering Restrictions

Technical Product Manual DCT1900

Absorption and Reflection

Base Station Planning

Total Area Coverage

Architecture

Departmental Differences

Site Survey

Measurement of Typical Cell Size

Atotal

Base Station Count Estimating

Technical Product Manual DCT1900

Data Limited Length of the Base Station Cable

Base Station Powering

Powering Base Stations by a Remote Power Supply

Power Limited Length of Base Station Cable

1 -48V External Source Powering

Powering Base Stations via the Modular Cabinet

How the Values in the Tables are Calculated

Tables

⎛ U

CLU SLU

Tables

Cable

AWG 0.5 mm wire size ∅

Example

Power Consumption from Power Supply Related to Cable Length

Power Consumption Related to Cable Length

Technical Product Manual DCT1900

Traffic Capacity of the Radio Exchange

Traffic Capacity of the System

Erlang Values Expressed in Call-Minutes

Traffic Capacity of the Base Stations

Traffic Capacity of the System

Technical Product Manual DCT1900

Radio Exchange

Relation between Parts

Cables

Power Supplies

Installation Instructions

Technical Product Manual DCT1900

Modular Cabinet Installation Steps

Cell Link Unit CLU-S -REX-BRD0016 or Rofnb 157 16/2

Central Processing Unit CPU REX-BRD0004 or 2/ROFNB 157 19/2

Central Processing Unit CPU2 REX-BRD9033, REX-BRD9034

Cell Link Unit CLU REX-BRD0014 or Rofnb 157 11/2

Base Station KRC 101 1371

Digital Trunk Unit DTU-E1 REX-BRD0002 or 2/ROFNB 157 13/1

Modular Cabinet CLU/SLU to Base Station Cabling

Modular Cabinet Power Cabling

Modular Cabinet Connection Board Mccb Roanb 101 28

Modular Cabinet CPU Cabling

Modular Cabinet Cables

Modular Cabinet LTU Cabling

Modular Cabinet DLU Cabling

Use of TDR

Technical Product Manual DCT1900

Introduction

Technical Product Manual DCT1900

ESD Socket

Safety and Regulatory Information

General

Environmental Requirements

Miscellaneous Items

Switch Room

Equipment Verification

Recommended Board Positions

Modular Cabinet Installation Steps

Main Steps of Installation

Labels

Switching On/Off

Unpacking

Charging Portable Telephone Batteries

Position of the Board Position Label

Connector Positions and Examples of Cable Labelling

Technical Product Manual DCT1900

Modular Cabinet REX-BAS9021 or Bdvnb 101 01/2

Contents of the Box

Installation Area for the Modular Cabinets

Installation of the Modular Cabinets

Bottom view

Parts of the Modular Cabinet

Fuse Wrist strap connector Power on/off switch

Pre-mounting of a Modular Cabinet in a One Cabinet System

Pre-mounting of Modular Cabinets in a Multi Cabinet System

Placement of the Shielding Gaskets Distance adjustment plate

Torx screwdriver nr

Sync port installation set Ntmnb 101

Mounting the Modular Cabinets to the Wall

Ground Plate

Connection to Protective Ground

Modular Cabinet must be connected to protective ground

Connection of Wrist Strap for ESD

10 Backplane of Modular Cabinet

Interconnecting Modular Cabinets

Add a Cabinet

Procedure

Placing the Securing Bar

Technical Product Manual DCT1900

Technical Product Manual DCT1900

Schedule Down Time

Do not mount the new cabinet

Technical Product Manual DCT1900

Technical Product Manual DCT1900

Functionality

Maintenance

Central Processing Unit CPU REX-BRD0004 or 2/ROFNB 157 19/2

Board Description

Synchronization Topology

Strap Settings

Providing framing clock to DTU or DLU source

When master Accepting framing clock from DTU or DLU source

LEDs

Connectors

Reset Button

Use ESD precautions

Installation

Fpga Installation

CPU-REX-BRD0004 or 2/ROFNB 157 19/2

Technical Product Manual DCT1900

System Boards

General Specifications

Central Processing Unit CPU1 REX-BRD0004 or 2/ROFNB 157 19/2

Speech Link Unit, SLU REX-BRD0015 or Rofnb 157 16/1

Speech Processing Unit, SPU-S REX-BRD0017 or Rofnb 157 16/3

Cell Link Unit, CLU-S REX-BRD0016 or Rofnb 157 16/2

Line Termination Unit, LTU REX-BRD0007 or Rofnb 157 02/06

Line Termination Unit , LTU2 REX-BRD0019A

Standard 712 Method Kbit/s A-law or μ−law PCM‘

Digital Line Specification

Straps

Cell Link Unit CLU REX-BRD0014 or Rofnb 157 11/2

CLU REX-BRD0014 or Rofnb 157 11/2

Power Distribution on the CLU

Install-DCT1900/R8/mw

Cell Link Unit CLU-S -REX-BRD0016 or Rofnb 157 16/2

CLU-S REX-BRD0016 or Rofnb 157 16/2

Power Distribution on the CLU-S

Technical Product Manual DCT1900

Speech Link Unit SLU REX-BRD0015 or Rofnb 157 16/1

SLU REX-BRD0015 or Rofnb 157 16/1

Base Station Power Distribution on the SLU

Technical Product Manual DCT1900

Speech Processing Unit SPU-S REX-BRD0017 or Rofnb 157 16/3

Straps and Connectors

SPU-S REX-BRD0017 or Rofnb 157 16/3

Straps should be placed in the twisted pair position 120 Ω

Digital Trunk Unit DTU-E1 REX-BRD0002 or 2/ROFNB 157 13/1

Each DTC has its own LEDs

DTC2 DTC1

11-4

Jumpers

Setting of the Jumpers

DTC2

12-4

Red Normally off. Watch-dog LED not significant

13-2

DTU-T1- REX-BRD0021 or 2/ROFNB 157 13/3

13-4

LTU supports 8 two wire analog connections to a PBX

14-2

JP5

Set-Up

CPU Settings

Application.hex Version Download Procedure

Programming

FPGA.mcs Version Download Procedure

DLU REX-BRD0023

Firmware

Contents of the Box

Power Distribution

Base Station KRC 101

Status LED Green/Red/Orange Base Station Status

LEDs Fig

Base Station Cover and Back

Base Station Cabling

Hardware PN Rev Firmware/Software Application Firmware PN

Base Station Cable Delay Measurement

16-5

Connecting the Base Station Plug to the Cable

Installation Criteria

Instructions Ceiling Mount Kit

Base Station Mounting Indoor 16.6.1 Wall Mount

Ceiling Mount

Cut Mounting Clip Adhere plastic spacer to the mounting clip

Ceiling Bracket with Ceiling Clips attached to Base Station

Base Station Mounting to Factory Ceiling I Beams

Mounting Technique

Introduction

Base Station Mounting Outdoor

Outdoor Base Station Mounting Instruction

Mounting Instructions

Building Corner

16-14

Weatherproof Housing Rear view

Weatherproof Housing rear view

16 Mounting Plate Small Pattern

17 Mounting Plate Large Pattern

Modular Cabinet Connection Board Mccb Roanb 101

Fuses

DTU Cable Ground Strap Settings

DTC In/Out Connectors

DTU Coax Cable Ground Strap Settings on Mccb

DTC1, DTC2, DTC3, DTC4

Modular Cabinet Connection Board Mccb Roanb 101

17-6

Synchronization Distribution Board REX-BRD0006 or Roanb 101

To CPU

External Sync Cable

External Sync Cable TSR 951

Sync Input Cable Delay Measurement

18-4

Modular Cabinet Bdvnb 101 01/3 R2, R3

Modular Cabinet Power Cabling

Power Connection to the Modular Cabinet

Factory Fitted Power Cabling

Filter Top of Filter

Modular cabinet powered by a -48Vdc PBX power supply

19-5

Mccb

Red

Modular Cabinet REX-BAS9021A/1B

10 Power Connection to the Modular Cabinet

11 Power Connections to Top of Filter

19-11

TS R N B 101

19-13

PW1 PW2 PW3 PW5 PW6PW7 PW-EXT PW4 PW3 PW2

Modular Cabinet CPU Cabling

Connections to the Mccb

20.2 CPU1 Cabling

SDB

Connections to the SDB

Connection to the PC, Printer, and SMS System

Cable Tie Blocks on the Ground Strip

CPU1 Sync Port Pin Connections

Synchronization Data Board SDB replacement Cable AWS1154

Connection to Alarm Device

CPU1 to CPU1 Figure

Connection of the Sync Cable

CPU2 Board Connections

20.4 CPU2 Cabling

Connection to the Sync Cable

CPU2 Sync Port Connector

CPU2 Sync Cable AWS1153

CPU2 to CPU2 More than 2 REs Figure

Master Cable Output

Mixing CPU1 and CPU2 based Systems

CPU1 to CPU2 Connection

10 CPU2 to CPU1, CPU2 Master, CPU1 Slave, Multiple REs

Ground Strip with Shielding Clamps

Modular Cabinet CLU/SLU to Base Station Cabling

CLU/SLU to the MDF

Installation of Cables

Cabling from the MDF to the Base Station

Base Station Power

TOP

This is not Pinned OUT AS a 568A or 568B Connector

Local Powering of a Base Station

CLC

Record Keeping

Identification of the Cable Pairs in NTM/TSRNB 101

CLU to 66 Block Cabling

Red SC1-0 Cicuit

Number Delay Location of Base Station

21-12

Modular Cabinet DTU Cabling

DTC Connections on the DTU-E1

Installation DTU-E1

DTC Connections on the DTU-T1

Installation DTU-T1 CAS or CCS

22-4

Modular Cabinet LTU Cabling

LTU/MDF Cable Connections to the LTU

LTU to 66 Block Cabling

Connector Cable Pair-In Wire Color Signal Name

Modular Cabinet DLU Cabling

DLU Board

Connection to PBX’s

Table -1 Pinout

Use of TDR

Determining the Delay of Remote Base Station Cable

Transmitted and Reflected Pulses

Examples

25-4

Modular Cabinet Cables

Mains Power Cord RPM 113 Power Cable Filter/Switch Trenb 101

Mccb Power Cable Trenb 101

Mccb Power Cable Trenb 101

Power Cable Switch/Fuse Trenb 101

Power Cable Switch/Fuse Trenb 101

Power Cable Fuse/Backplane Trenb 101

Power Cable Switch/Backplane Trenb 101

PC Cable Tsrnb 101 22D

PC or SMS Cable Tsrnb 101 22D

Printer Cable Tsrnb 101

Signal PIN DTR DCD RTS CTS GND

CPU/MCCB Serial Connection Cable Tsrnb 101

26.8 CPU/MCCB Serial Connection Cable Tsrnb 101

Fold back shield 11 .4 Notch

General Alarm Cable Tsrnb 101

General Alarm Cable Tsrnb 101

26.10 CLU/MDF Cable Set NTM/TSRNB 101

10 CLU Cable Connector a

11 CLU Cable Connector B

12 CLU/MDF Cable Set NTM/TSRNB 101

13 LTU/MDF Cable Set NTM/TSRNB 101

26.11 LTU/MDF Cable Set NTM/TSRNB 101

26.13 CLU/MDF Cable Set, Long NTM/TSRNB 101

26.12 CLU/MCCB Power Cable Tsrnb 101

15 CLU/MDF Cable Set NTM/TSRNB 101

16 CLU/MDF Cable Set NTM/TSRNB 101 46 cont’d

17 CPU1/SDB Twisted Pair Sync Cable Tsrnb 101

26.14 CPU1/SDB Twisted Pair Sync Cable Tsrnb 101

18 DTU Twisted Pair Cable E1

19 DTU Twisted Pair Cable T1

Sync Cable TSR 951

20 Wiring Diagram External Sync Cable

26-22

Commissioning

Technical Product Manual DCT1900

Synchronization Test

Visual Checks

Portable Telephone Test

Radio Coverage Verification

Comm-DCT1900/R8/mw

Commissioning, Introduction

Technical Product Manual DCT1900

Test

Synchronization Test

Technical Product Manual DCT1900

Test

Radio Coverage Verification

Base Station Test

Area Coverage Test

Display Layout MER Test

Evaluation

Technical Product Manual DCT1900

Portable Telephone Test for SMS

Portable Telephone Test

Technical Product Manual DCT1900

Availability of all System Boards and Base Stations

Visual Checks

LEDs on the System Boards

Technical Product Manual DCT1900

Radio Exchange Tests

General Alarm

Battery Back-up

Technical Product Manual DCT1900

Maintenance

Technical Product Manual DCT1900

Hapter

Maintenance Philosophy

Test and Maintenance Software

Fault Signalling

Fault Finding Procedures

Service Messages

Part Replacement

Preventive Maintenance

Maintenance Philosophy

Concept of Maintenance

Technical Product Manual DCT1900

Test and Maintenance Software

Board Controllers and Peripherals

Error Handling

Fault Counters

Diagnostics

Test

Error Tables

Maintenance

Board Announcement

Testing

Board Power-on Test

Board Test

3 24-Hour Test

Resets

Reset Types

Ack Test

Reset Table

Counters for Peripherals

Relative Counters

Counters for CPU

Counters for Board Controllers

Reset Counters and Error Tables

System Service Required

Fault Signalling

General Alarm/Service Message

General Alarm Signal

Explanation of States

Checking Component Status through Cordless System Manager

DTU Layer States Layer 1 L1

Individual User Complaints

Base Station BS States

DLU Port States

LEDs

Common User Complaints

LED

LEDs on System Boards

LEDs on CPU

LED 1

Power LED

LEDs on Base Station

Dynamic Channel Allocation DCA Display Portable Telephone

ALL-FP + RSS

Activating DCA mode

Link Info

Explanation of DCA Service Displays

ChannelInf

All-FP+RSS

FP-Info

SysList

TimeSlots

SysOrder

MER tests

Last Error

How to display messages

Service Messages

Service Message Format

Handling Error Messages

Comment to the Table

Fault Codes

Fault Codes in Service Table

Service

Comment to Fault Codes

Replacing the CPU

Part Replacement

General Rules

Replacing a System Board

Expansion of Modular Cabinet System

Replacing a Base Station

Re-positioning Boards

Fuses

Modular Cabinet Fuses near power switch

Modular Cabinet Fuse near power switch to Backplane

Adding Boards

Procedure B

Board Reset

Procedure a

Technical Product Manual DCT1900

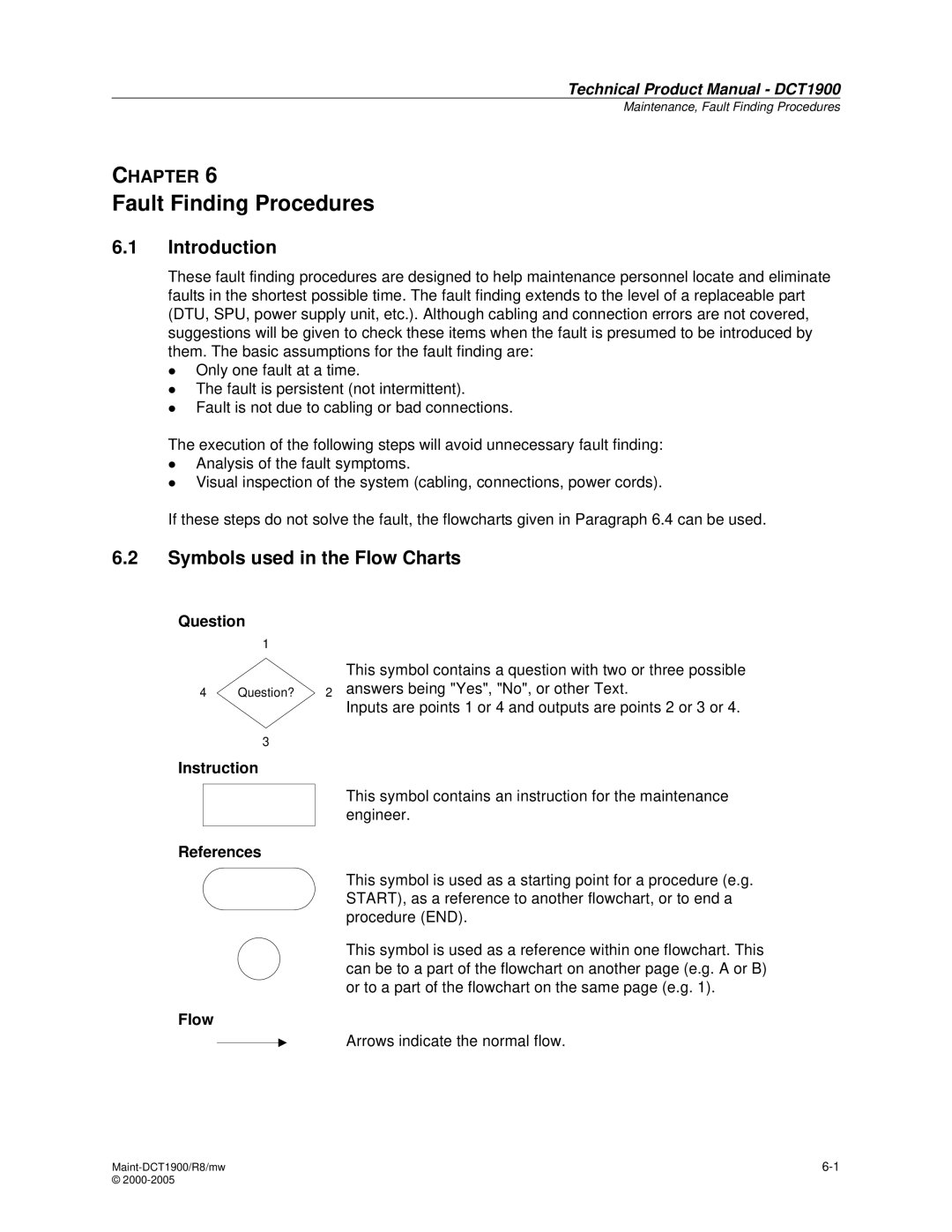

Symbols used in the Flow Charts

Fault Finding Procedures

How Defective Items are Indicated

Fault Finding Flowcharts

System Manager Control Service

Yes Adapter When using CLU check related fuse

SDB

Individual User Complaint

No Dial Tone

END

Errors

Corrupted. Re-initialize Portable

Check PC cabling From COM1 via

Technical Product Manual DCT1900

Glossary

Gloss-DCT1900/R8/mw 2000-2005

Glossary

Gloss-DCT1900/R8/mw

Glossary

Rssi