Automation and Drives - SCE

6.CONTROL PROGRAM 'BUCKET ELEVATOR’ ON THE PROFIBUS DP/PROFINET

6.1Assigning the Process Data for the SINAMICS G120

With the process data, the control words and the setpoints (PLC

The structure of the process data (PZD) area is the same in the sequence of its elements (words) for the two indicated interfaces by means of PROFIBUS DP and PROFINET.

| Process Data 1 | Process Data 2 |

Request message | Control word | Main setpoint |

(SPS | (STW) | (HSW) |

|

|

|

Response message | Status word | Main actual value |

(SINAMICS | (ZSW) | (HIW) |

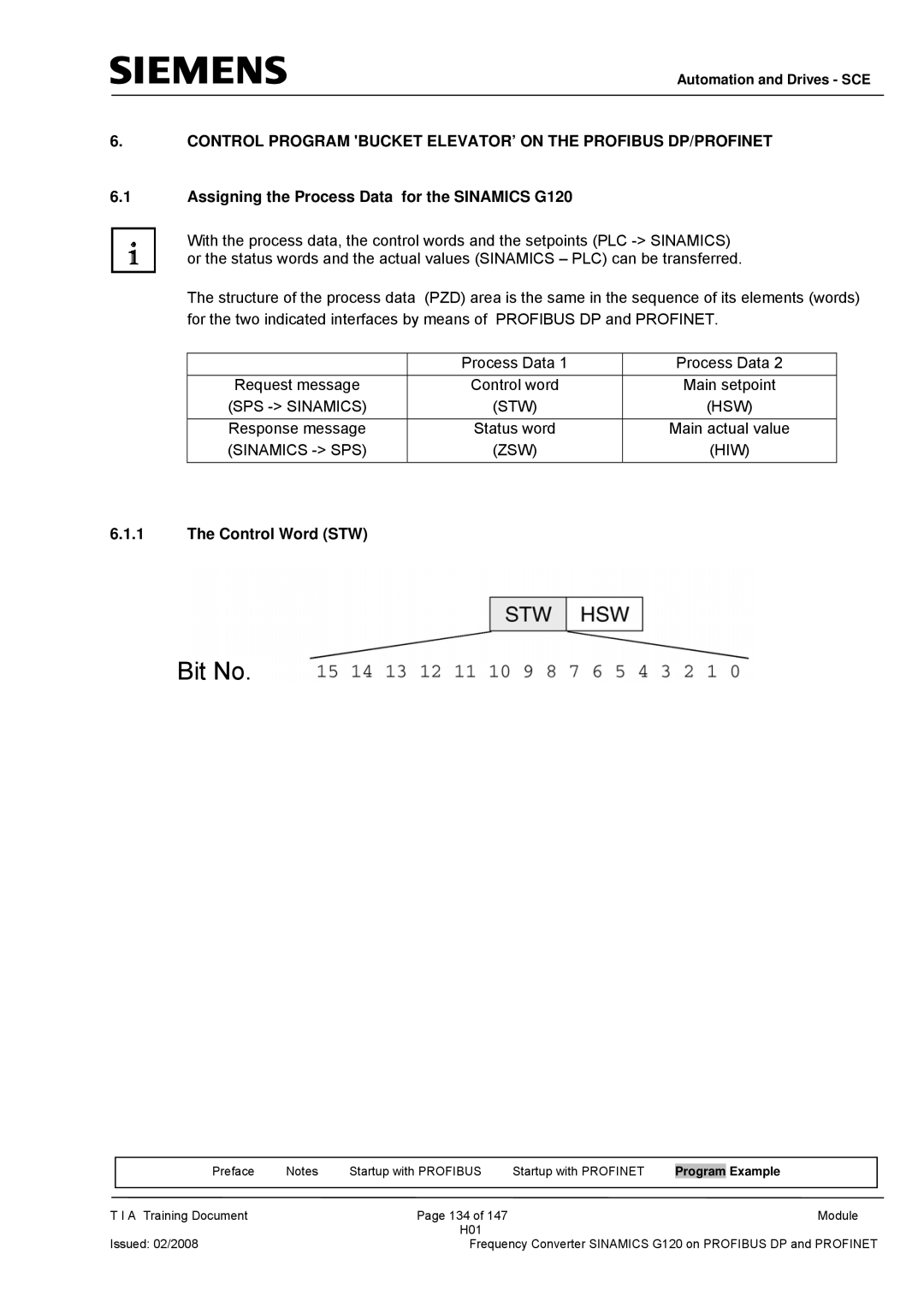

6.1.1The Control Word (STW)

Bit No.

|

|

|

|

|

|

|

| Preface | Notes | Startup with PROFIBUS | Startup with PROFINET | Program | Example |

|

|

|

|

|

|

|

T I A Training Document |

| Page 134 of 147 |

|

| Module | |

|

|

| H01 |

|

|

|

Issued: 02/2008 |

| Frequency Converter SINAMICS G120 on PROFIBUS DP and PROFINET | ||||