Operator

USA

Product Recycling and Disposal

European Union

Domestic/Household Environment

Professional/Business Environment

DocuTech 128/155/180 HighLight Color Operator Guide

Table of Contents

Problem Solving

Technical information

Service and supplies

DocuTech 128/155/180 HighLight Color Operator Guide

Introduction

Conventions

System safety

Laser safety

Ozone safety

Operation safety

European Union declaration of conformity

Safety notices

Electricity at Work Regulation UK

Regulation

Check your understanding

Would like to carry out my own safety tests on the Xerox

Additional queries

Equipment in my premises

Require records of all tests

Safety notices

Electronic reprographics process

DocuSP controller DocuTech Printer

Functional overview

Optional Components

Data stream resolution

Data formats supported

Paper weights

Stock specifications

Special stocks

General paper characteristics

Graphical user interface overview

System software and job flow

Job

Input queue

Decomposer

Printer overview

Output queue

Printer

High volume printer

Feeder/paper tray High volume printer

Indicator

Trays 3, 4, 5, and 6 high-capacity trays 2600 sheets each

Ready to Open

Please Wait

Sample tray

Purge tray

Inverter feeder/stacker

On stackers

Feeder/stacker modules

More High volume printer configurations

Production publisher

Convenience tray

Interposer

Interposer production publisher only

Finisher

Bindexer

Stitcher

Stacker

Binder

Top tray

Bypass transport

Bypass transport on the High volume printer

By 10 inch enablement kit

Bypass transport on the production publisher

Paper paths

High volume printer paper path

11. Route of paper through the high volume printer

System components

Production publisher paper path

Bypass transport paper path

High volume printer bypass transport paper path

System

System Hardware

DocuSP controller

Controller overview

Accessing DocuSP remotely Remote Workflow

Moving the controller

Tape drives overview

Do not

Peripheral cabinet 9-track and 18/36-track tape drives

14 -track cartridge tape drive

Paper sizing and print speed

15. Peripheral cabinet

System components

System components

Cleaning and maintenance overview

Necessary Precautions

Finisher precaution

Routine maintenance

Paper

Storing paper

Recommended temperature and humidity for Paper storage

Conditioning paper

Paper curl

Paper conditioning

Adding paper to tray 1 or

Preparing the paper tray

Using the custom transfer assist blade

Positioning the stack

Paper Size Set Paper Size

Adjusting for paper curl

Measuring the paper curl

Move green Decurler lever

Adjusting the decurler lever

Locating the decurler lever

Maintaining the printer

Replacing the black dry ink bottle

Replace the black dry ink bottle

Removing the empty bottle

Replacing the highlight color container

10 Removing the paper seal

11 Highlight color container

Removing the CCU using the CCU cart

Changing the highlight color Customer Changeable Units

12 Leveling the cart

13 Unlatching the CCU

Inserting a CCU

15 Closing the top cover

17 Turning the backup roller handle Counterclockwise

Removing the CCU using the service stand

Storing the cart and CCU

19 Unlatching the CCU

Adding fuser shield

20 Removing the CCU from the printer

21 Opening the fuser drawer

22 Preparing to add fuser blend

23 Adding the fuser blend

Waste containers

Replacing the 128/155/180 HLC developer waste container

Replacing the 128/155/180 toner waste bottle

26 Opening the HLC module door

27 Flat cap on waste bottle

Wire Module Removal and Replacement

29 Wire module retainer springs

Routinemaintenance

Cleaning the system and its components

Cleaning the 18/36-track cartridge tape drive

Cleaning the 26-track cartridge tape drive

Cleaning the DVD drive

Cleaning the diskette drive

Cleaning the sensors and the reflecting surfaces

Cleaning the Q850 and Q861 sensor

30 Area 4 and green handle

Cleaning the Q1011/1009 sensor and mirror

Cleaning the Q1106 and Q1166 sensors

Cleaning the Q1107 sensor

33 Q1106 and Q1166 sensors

Cleaning the Q1164 sensor

34 Q1107 sensor

Cleaning the display

Cleaning the exterior surfaces of the system

Clearing or cleaning the finisher sensors

Clearing the Q1201 sensor

Clearing the Q1202 and Q1203 sensors

37 Locating the Q1201 sensor

38 Locating the Q1202 and Q1203 sensors

Cleaning the Q1222 and Q1210 sensors

40 Locating the Q1222 and Q1210 sensors

Clearing the Q1205, Q1206, and Q1207 sensors

41 Locating the Q1222 and Q1210 sensors

Clearing the Q1213 sensor

42 Locating the Q1205, Q1206, and Q1207 sensors

Clearing the Q1221, Q1218, and Q1227 sensors

43 Q1213 sensor

Cleaning the binder

44 Locating the Q1221, Q1218, and Q1227 sensors

45 Opening the binder drawer

Cleaning the binder tape guides

Cleaning the binder platen

Cleaning the flappers

48 Cleaning the binder platen

Cleaning the calipers

49 Cleaning the flappers

Closing the binder

Replacing the stitcher spool a

51 Releasing the stitcher head

52 Removing the stitcher wire plug

53 Removing the wire from the tubing

55 The measuring bracket

57 Replacing the pin

58 Removing the paper wrapper

Storing the binder tape reels

60 Storing binder tape in a cool, dry place

Replacing the binder tape reel

62 Opening the binder drawer

63 Removing the tape

65 Locking the reel

67 Threading the tape to the pressure roll

Adjusting the binder tape registration

69 Cutting the tape

70 Locating the binder tape knob

71 Adjusting the tape position up

Routine maintenance

How problems are displayed

Printer faults and fault windows

Resolving a processor problem

When a fault occurs

Resolving a processor problem

ProblemSolving

Sheets from the fuser

ProblemSolving

Solving print quality problems

Clearing paper jams

Checking job integrity following a paper jam

Area

Area

Area

Area

Using the pinch lever to access area

10 Area 11 all feeder/stackers

11 Area 12 all feeder/stackers

Clearing paper jams in the Feeder/Stackers

12 Area

14 Area

15 Area

16 Area

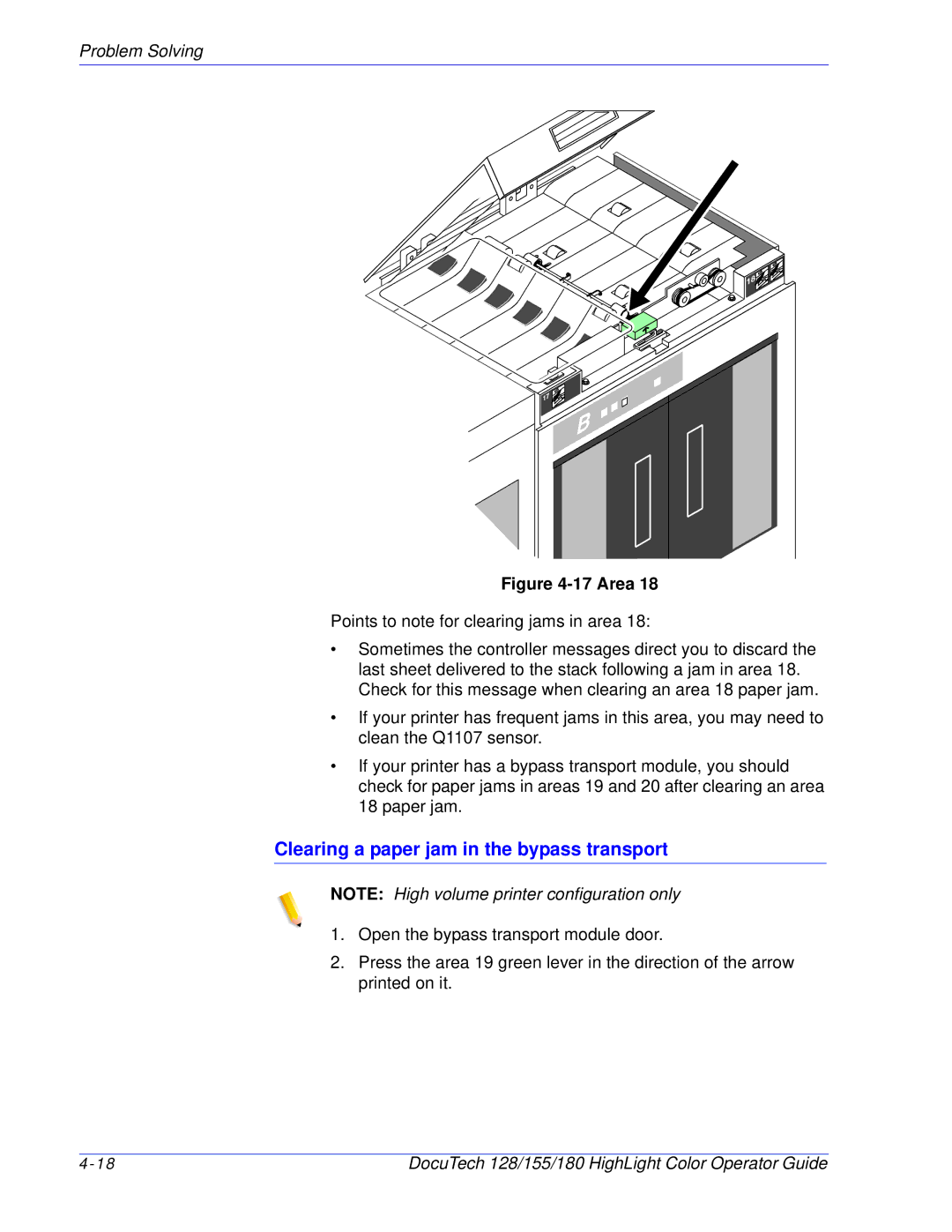

Clearing a paper jam in the bypass transport

17 Area

18 Area

Clearing a misfeed feeder tray fault

19 Area

ProblemSolving

Incorrect paper size message

Interposer problems

Finisher problems

Resolving a finisher problem

Resolving a finisher problem

Binder tape fault

Stitcher spool a fault

23 Stitcher head release handle

24 Removing the stitcher wire plug

25 Cutting the wire

27 Removing the wire fragments

Customer Support Center

Checking paper curl

29 Location of printing system serial number

Problem Solving

DocuTech printer specifications

Printer rates

Paper tray capacities

All trays

Technical information

Additional paper capacities

Inverter

Top tray

Stacker

Printer satisfaction guides

Stock storage

Improving the feeding reliability

Stitches per spool

Stock satisfaction guides

Satisfaction guide for paper trays 1

Satisfaction guide for paper trays 3, 4, 5,

Using various stocks

Satisfaction guide for 2-sided printing

Satisfaction guide for various stocks

Stock Type Instructions for use

Technicalinformation

Using non-standard stock

Stock width impact on system performance

Paper stock rotation

Background

Stock length impact on system performance

Limitations

Common US paper sizes

Other paper sizes that can be rotated

Finisher satisfaction guides

10. Stacker capacity

11. Stitcher satisfaction guide

11. Stitcher satisfaction guide

12. Binder satisfaction guide

13. Top tray satisfaction guide

13. Top tray satisfaction guide

Xerox support services

Customer support

Supplies service

Operator training

Service and supplies

Routine maintenance

Meter reading and reporting

Consumable supplies table

Consumable supplies

Transparencies

Labels

Gummed

Black

Cleaning

Wire Modules

Stitcher Wire

Royal Blue

Supplies checklist

Description Quantity Date of order Ordered