UMC800 Overview

UMC800 Description

UMC800 Overview

UMC800 Description

The Universal Multiloop Controller (UMC800) is a modular controller designed to address the analog and digital control requirements of small unit processes. With up to 16 analog control loops, four setpoint programmers, and an extensive assortment of analog and digital control algorithms, the UMC800 is an ideal control solution for furnaces, environmental chambers, ovens, reactors, cookers, freeze dryers, extruders, and other processes with similar control requirements.

Accommodating up to 64 universal analog inputs, 16 analog outputs, and 96 digital inputs/outputs, the UMC800 provides the appropriate balance of input and output hardware for these smaller unit processes.

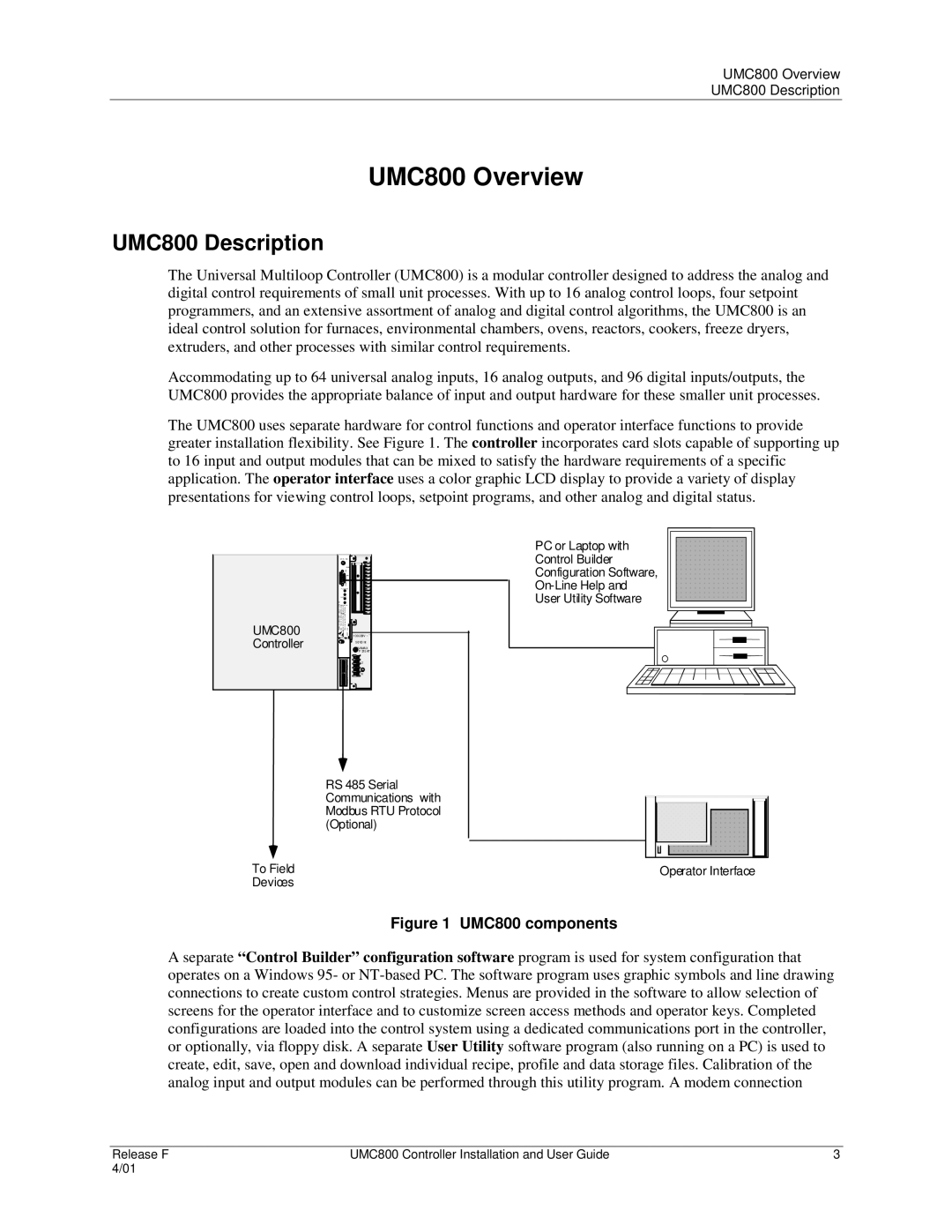

The UMC800 uses separate hardware for control functions and operator interface functions to provide greater installation flexibility. See Figure 1. The controller incorporates card slots capable of supporting up to 16 input and output modules that can be mixed to satisfy the hardware requirements of a specific application. The operator interface uses a color graphic LCD display to provide a variety of display presentations for viewing control loops, setpoint programs, and other analog and digital status.

UMC800 Controller

|

|

|

| ON |

|

|

|

| CONFIGURATI |

adir an T L510 1/S | bat ter y m ay | expl osi o n. | truct ions. |

|

atte ry with T | of a noth er | ri sk of fire or | gu ide f or ins |

|

Repla ce b | only . Use | prese nt a | See us ers | LAY |

|

|

|

| DISP |

|

|

|

| A |

|

|

|

| COMM |

|

|

|

| COMM B |

_

100- 230V ~

50/ 60 Hz

100VAMAX. F 3,15 AT

![]() L1

L1

L2/

N

PC or Laptop with Control Builder Configuration Software,

RS 485 Serial Communications with Modbus RTU Protocol (Optional)

To Field | Operator Interface |

Devices |

|

Figure 1 UMC800 components

A separate “Control Builder” configuration software program is used for system configuration that operates on a Windows 95- or

Release F | UMC800 Controller Installation and User Guide | 3 |

4/01 |

|

|