Mounting and Wiring

Mounting the Controller

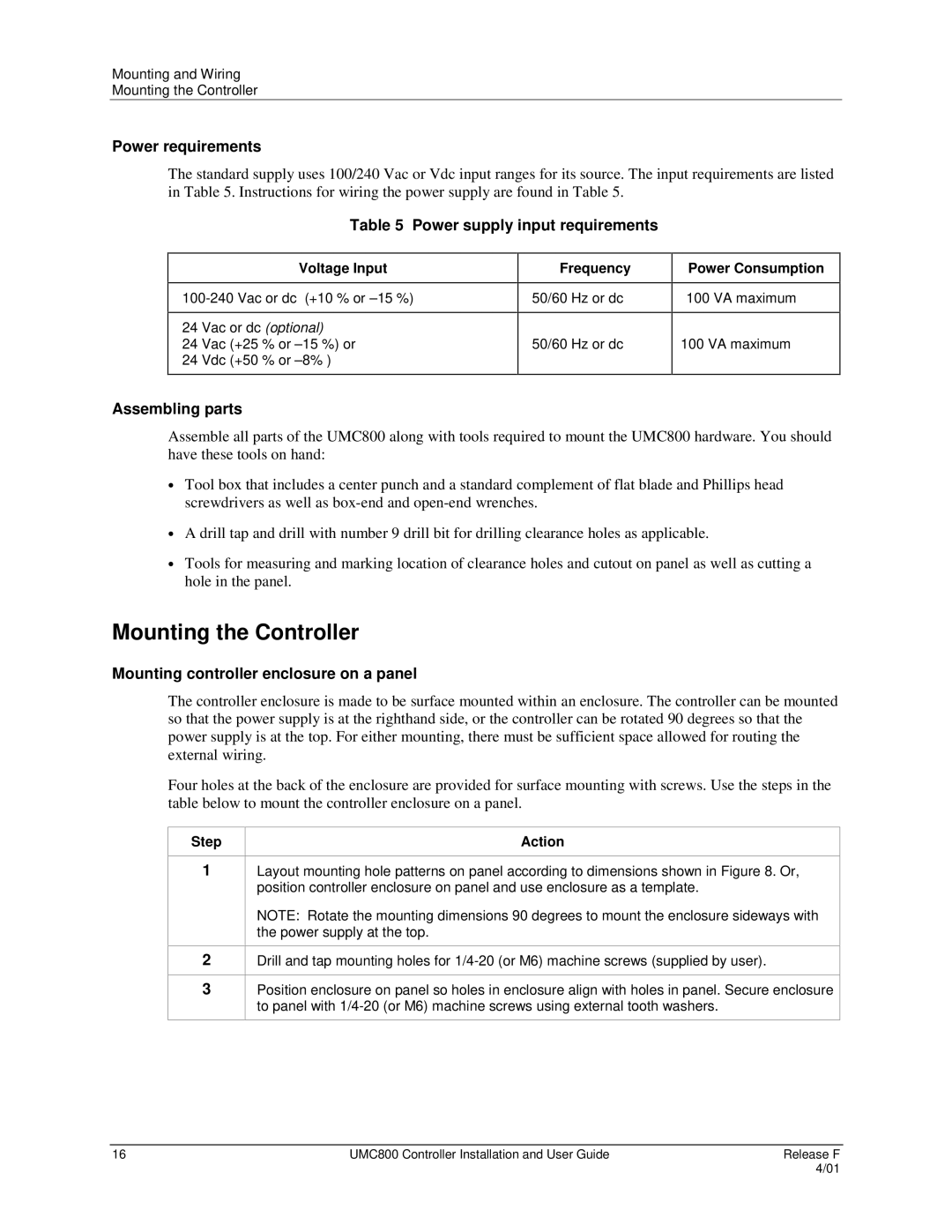

Power requirements

The standard supply uses 100/240 Vac or Vdc input ranges for its source. The input requirements are listed in Table 5. Instructions for wiring the power supply are found in Table 5.

Table 5 Power supply input requirements

Voltage Input

24 Vac or dc (optional)

24 Vac (+25 % or

24 Vdc (+50 % or

Frequency

50/60 Hz or dc

50/60 Hz or dc

Power Consumption

100 VA maximum

100 VA maximum

Assembling parts

Assemble all parts of the UMC800 along with tools required to mount the UMC800 hardware. You should have these tools on hand:

•Tool box that includes a center punch and a standard complement of flat blade and Phillips head screwdrivers as well as

•A drill tap and drill with number 9 drill bit for drilling clearance holes as applicable.

•Tools for measuring and marking location of clearance holes and cutout on panel as well as cutting a hole in the panel.

Mounting the Controller

Mounting controller enclosure on a panel

The controller enclosure is made to be surface mounted within an enclosure. The controller can be mounted so that the power supply is at the righthand side, or the controller can be rotated 90 degrees so that the power supply is at the top. For either mounting, there must be sufficient space allowed for routing the external wiring.

Four holes at the back of the enclosure are provided for surface mounting with screws. Use the steps in the table below to mount the controller enclosure on a panel.

Step

1

2

3

Action

Layout mounting hole patterns on panel according to dimensions shown in Figure 8. Or, position controller enclosure on panel and use enclosure as a template.

NOTE: Rotate the mounting dimensions 90 degrees to mount the enclosure sideways with the power supply at the top.

Drill and tap mounting holes for

Position enclosure on panel so holes in enclosure align with holes in panel. Secure enclosure to panel with

16 | UMC800 Controller Installation and User Guide | Release F |

|

| 4/01 |