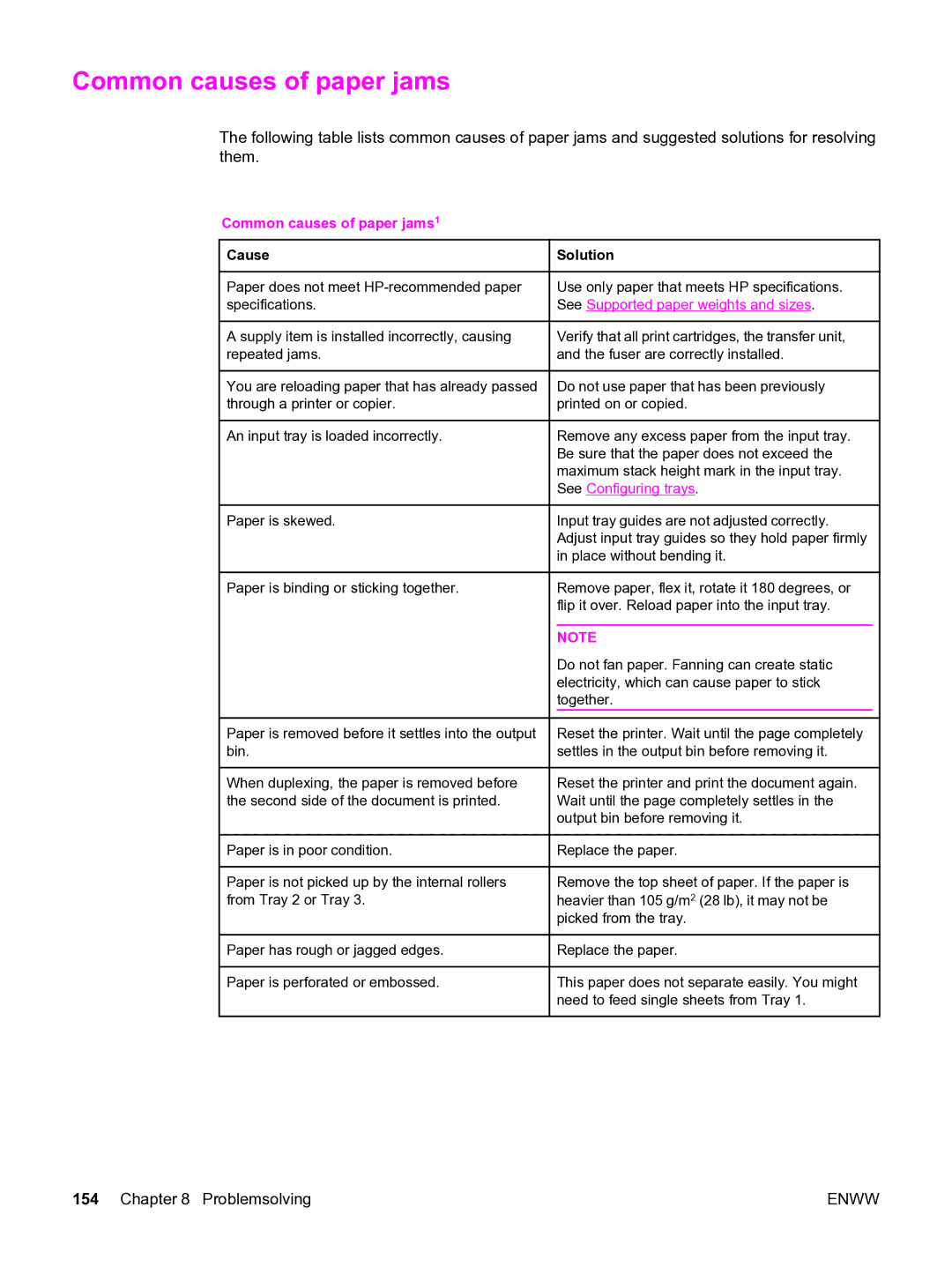

Common causes of paper jams

The following table lists common causes of paper jams and suggested solutions for resolving them.

Common causes of paper jams1

Cause

Cause

Paper does not meet

A supply item is installed incorrectly, causing repeated jams.

You are reloading paper that has already passed through a printer or copier.

An input tray is loaded incorrectly.

Solution

Solution

Use only paper that meets HP specifications. See Supported paper weights and sizes.

Verify that all print cartridges, the transfer unit, and the fuser are correctly installed.

Do not use paper that has been previously printed on or copied.

Remove any excess paper from the input tray. Be sure that the paper does not exceed the maximum stack height mark in the input tray. See Configuring trays.

Paper is skewed. | Input tray guides are not adjusted correctly. |

| Adjust input tray guides so they hold paper firmly |

| in place without bending it. |

Paper is binding or sticking together.

Paper is removed before it settles into the output bin.

When duplexing, the paper is removed before the second side of the document is printed.

![]() Paper is in poor condition.

Paper is in poor condition.

Paper is not picked up by the internal rollers from Tray 2 or Tray 3.

![]() Paper has rough or jagged edges.

Paper has rough or jagged edges.

Paper is perforated or embossed.

Remove paper, flex it, rotate it 180 degrees, or flip it over. Reload paper into the input tray.

NOTE

Do not fan paper. Fanning can create static electricity, which can cause paper to stick together.

Reset the printer. Wait until the page completely settles in the output bin before removing it.

Reset the printer and print the document again. Wait until the page completely settles in the output bin before removing it.

![]() Replace the paper.

Replace the paper.

Remove the top sheet of paper. If the paper is heavier than 105 g/m2 (28 lb), it may not be picked from the tray.

![]() Replace the paper.

Replace the paper.

This paper does not separate easily. You might need to feed single sheets from Tray 1.

154 Chapter 8 Problemsolving | ENWW |