Use

Page

User Guide

Copyright and License

HP customer care

HP direct ordering for accessories or supplies

HP service information

Iii

HP Toolbox

HP service agreements

HP support and information for Macintosh computers

Table of contents

Managing and maintaining the printer

Problem solving

Vii

Appendix a Supplies and accessories

Viii

Appendix B Control panel menus

Index

Printer basics

Setting up the printer

Quick access to printer information

Where to look for more information

Using the printer

Letter Description

Printer configurations

Model descriptions

Printer model HP LaserJet 4250 series

One 100-sheet tray and two 500-sheet trays

Speed

Printer features

Resolution

Paper handling

Interface connections and networking

Memory and processor

Language and fonts

Energy savings

Accessibility

Print cartridge

Economical printing

Accessories and supplies

Printer parts

One optional 1,500-sheet feeder

Accessory lights

Interface ports

Locking and unlocking optional accessories

Moving the printer

Control panel

Control-panel layout

Button

Control-panel buttons

Control-panel lights

Function

Printing control-panel menus

Using the printer Help system

To print a control-panel menu map

To change a control-panel setting

Changing printer-control-panel configuration settings

Changing control-panel settings

Job storage limit

Show address

Job held timeout

To set the job held timeout

To set the job storage limit

Tray behavior options

To show the IP address

To set Use Requested Tray

To set Manually Feed Prompt

To set the printer default for PS Defer Media

Sleep Delay

To set Size/type prompt

To turn the Sleep Mode on or off

To set the Sleep Delay

Personality

To set the personality

Clearable warnings

Auto continue

To set the clearable warnings

To set the auto continue

Cartridge low

To set supplies-low reporting

Cartridge out

Jam recovery

To set the cartridge-out response

Language

To set the jam-recovery response

RAM disk

To set the RAM disk

To select the language

Unix

Software

Operating systems and printer components

PCL

Operating system

Printer drivers

Additional drivers

PCL PPD

Printer driver Help

Using the printer drivers

Select the correct printer driver for your needs

Properties

Properties or

Preferences

PPDs

Software for Macintosh computers

HP LaserJet Utility

Installing the printing system software

To install the printing system software

Installing Windows printing system software for networks

To install printer drivers in Mac OS

Installing Macintosh printing system software for networks

Double click Printer AppleTalk

Click Add Printer

For Mac OS

Next to USB Printer Selection, click Change

To remove software from Windows operating systems

Uninstalling the software

To remove software from Macintosh operating systems

Selecting print media

Weight Capacity2

Tray 1 supported sizes and weights

Size Dimensions1

Supported sizes of print media

Optional 1,500-sheet tray supported sizes and weights

Size Dimensions Weight Capacity

Optional envelope feeder supported sizes and weights

Optional duplexer supported sizes and weights

Size Dimensions Weight

Enww

Enww

Printing tasks

Customizing tray 1 operation

Selecting which tray is used for printing

Understanding tray order

Tray 1 TYPE=ANY Tray 1 SIZE=ANY

Printing by type and size of media locking trays

Media

Manually feeding media from tray

To print by type and size of paper

Selecting the correct fuser mode

Quality submenu

To select the stapler in the software Mac

Stapling documents

To select the stapler in the software Windows

To select the stapler at the control panel

Loading staples

To load staples

Loading tray

Loading trays

To load tray

Loading tray 2 or an optional 500-sheet tray

To load tray 2 or an optional 500-sheet tray

Loading an optional 1,500-sheet tray

To load an optional 1,500-sheet tray

Do not fan the media. Fanning can cause misfeeds

Enww

Printing to the top standard output bin

Understanding media output options

Printing to the rear output bin

Printing to the optional stacker or stapler/stacker

Orientation of paper when a stapler is installed

Loading envelopes in tray

Printing envelopes

To load envelopes in tray

Installing the optional envelope feeder

Feeding envelopes automatically optional envelope feeder

Removing the optional envelope feeder

To install the optional envelope feeder

To remove the optional envelope feeder

Loading envelopes in the optional envelope feeder

Handling menu

Printing on labels

Follow these guidelines when printing on labels

Printing on special media

Do not load or print on labels in the following ways

Printing on transparencies

TRANSPARENCY=LOW

Guidelines for printing on letterhead or preprinted forms

Printing on paper that has a special finish

Printing on small sizes, custom sizes, or heavy paper

Weight and sizes

Tray Minimum size Maximum size Supported weights

Guidelines for heavy paper

Setting custom paper sizes

Additional guidelines for small or narrow paper

To set custom paper sizes

Parts, accessories, and supplies

Printing on both sides of paper optional duplexer

Orientation of paper for duplexing

To duplex with the optional duplex-printing accessory

Layout options for printing on both sides of paper

To duplex manually

On the Finishing tab, select Print on Both Sides Manually

Canceling a print job

Changing the settings for a print job

Using the printer driver

Changing default settings

To change default settings in Windows 98 and Windows Me

To change default settings in Windows NT

To change default settings in Macintosh operating systems

To print a watermark on Windows computers all versions

Using printer-driver features

Printing watermarks

To print a watermark on Macintosh computers

To set a custom paper size on Windows computers

Setting a custom paper size

Printing multiple pages on one sheet of paper

On the Paper/Quality tab, click Custom

To set a custom paper size on Macintosh computers

Using EconoMode draft printing

Selecting print-quality settings

To use EconoMode draft printing on Windows computers

Using reduce/enlarge options

Selecting a paper source

To print covers or different pages on Macintosh computers

To print covers or different pages on Windows computers

On the Paper/Quality tab, click Use different paper/Covers

Quick copying a job

Using job-storage features

To print copies of a stored job

To delete a quick copy job

Deleting a quick copy job

Proofing and holding a job

To print the remaining copies of a held job

To delete a held job

Deleting a held job

Printing a private job

To specify a private job

To delete a private job

Deleting a private job

Storing a print job

To store a print job

To print a stored job

To delete a stored job

Managing and maintaining the printer

Using the embedded Web server

Opening the embedded Web server

Settings tab

Information tab

Networking tab

Other links

Using HP Web Jetadmin software

Supported browsers

Using the HP Toolbox

Supported operating systems

Windows

Status tab

Troubleshooting tab

To view the HP Toolbox

Utilitites folder. Double-click the HP Toolbox icon

Administrative settings

Device Settings window

Set up status alerts

Alerts tab

Toolbox links

Click Control Panel

Uninstalling the HP Toolbox

Double-clickAdd or Remove Programs

Managing and configuring printer drivers

HP Web Jetadmin software plug-in

Customization utility

Configuring e-mail alerts

Utitlity Information source

Setting the date and time

Setting the real-time clock

Setting the date format

Setting the date

Setting the time format

Setting the time

To print a configuration page at the control panel

Checking the printer configuration

Configuration

Menu map

That are installed

To print a supplies status page at the control panel

Supplies status

PS or PCL font list

To print a PS or PCL font list

Selecting PCL 6 and PCL 5 fonts

HP print cartridges

Print-cartridge authentication Print-cartridge storage

Managing the print cartridge

Non-HP print cartridges

Checking the supply level

Print-cartridge life expectancy

Cartridge-low and cartridge-out conditions

When the cartridge is low on toner or drum life

When the cartridge is out of toner or drum life

Cleaning the inside of the printer

Cleaning the printer

To clean the inside of the printer

Cleaning the fuser

To run the cleaning page manually

Running the cleaning page manually

Running the cleaning page automatically

To run the cleaning page automatically

Performing preventive maintenance

To reset the maintenance-kit counter

Replacing the stapler unit

To remove and replace the stapler unit

Replacing the stapler unit

Enww

Problem solving

119

Does the control panel display read READY?

Troubleshooting flowchart

YES

Can you print a configuration page?

See Configuration

Can you print from a program?

Job will not print PS error page or list of commands prints

Go to step

PERSONALITY=AUTO

Does the job print as expected?

Print job is not formatted correctly

There are print-quality problems

Paper is not fed correctly or is damaged

Go to Correcting print-quality problems

Configuration

Tray 1 Size and Tray

Cause Solution

Solving general printing problems

Cause

Solving general printing problems

Try printing a job from another program

Control-panel messages

Guidelines for using paper

Symptom Problem with paper Solution

Font list

Configuration

Printing special pages

Supplies status

Jam locations

Clearing jams

Clearing jams from the top-cover and print-cartridge areas

To clear jams from the top-cover and print-cartridge areas

To clear jams from the optional envelope feeder

Clearing jams from the trays

To clear jams from tray

To clear jams from tray 2 or an optional 500-sheet tray

To clear jams from the optional 1,500-sheet tray

Clearing jams from the optional duplexer

To clear jams from the optional duplexer

Clearing jams from the output areas

To clear jams from the rear output bin

Clearing jams from the fuser area

To clear jams from the fuser area

Enww

Clearing jams from the optional stacker or stapler/stacker

To clear staple jams from the optional stapler/stacker

Solving repeated jams

If paper jams occur frequently, try the following

Enww

Resolving persistent messages

Using the printer online Help system

Understanding printer messages

Interpreting control-panel messages

Parallel I/O

13.XX.YY JAM

Insufficient Memory

Parallel I/O Buffer Overflow

Xxxxx Error

Error

Fuser Error

XX Error

Control panel message 51.XY Error For help press

XY Error

To continue Sensor issue Turn off then on

To continue Turn off then on Description

66.XY.ZZ Input

Control panel message 59.XY Error For help press

Handling accessory

Device Failure

Permanent

Storage Error Settings Changed

66.XY.ZZ Output

Storage Write Fail

Control panel message Description Recommended action

8X.YYYY

EIO Error

Jetdirect Error

8X.YYYY Embedded

Card Slot X File Operation Failed

Card Slot Not Functional

Card Slot X Device Failure

Card Slot X File System is Full

Corrupt Firmware in External Accessory

Cleaning Disk Complete

Cleaning Disk

Chosen Personality not Available

EIO X Disk Device Failure

Different Paper Sizes in JOB

EIO X Disk

EIO X Disk File Operation Failed

Envelope Feeder Empty

EIO X Disk is Write Protected

EIO X Disk not Initialized

Insert or Close Tray

Internal Disk is Write Protected

Internal Disk File Operation Failed

Internal Disk File System is Full

Internal Disk not Initialized

Custom Load Tray Typesize

Manually Feed Typesize

Output Paper Path Open

NON HP Supply Installed

Current status message Description

For help press Paused To return to ready press Stop

RAM Disk File System is Full

RAM Disk Device Failure

RAM Disk File Operation Failed

RAM Disk not Initialized

ROM Disk Device Failure

Replace Cartridge

Current status message Replace Cartridge To continue press

ROM Disk File Operation Failed

Size Mismatch Tray

ROM Disk is Write Protected

ROM Disk not Initialized

Stapler LOW on Staples

Tray Typesize

Stapler OUT of Staples

TOO Many Pages in JOB to Staple Tray XX Typesize

Tray XX Empty Typesize

Waiting for Tray XX to Lift

Unsupported Data on FS Dimm in Slot

USE Tray XX Typesize

Warming UP

Pages in JOB to Staple appears on

Light Explanation and solution Solid green

Malfunction .XY.ZZ Output Device

Light Explanation and solution Blinking amber

Firmware in External Accessory

Replacing accessories or accessory components

Print-quality checklist

Correcting print-quality problems

Image defect examples

AaBbCc

Light print entire

Light print partial

Specks

Dropouts

Lines

Gray background

Toner smear

Loose toner

Repeating defects

Misformed characters

Repeating image

Skew

Curl or wave

Wrinkles or creases

Tire tracks

Vertical white lines

White spots on black

Scattered lines

Blurred print

Random image repetition

Troubleshooting network printing problems

Troubleshooting common Windows problems

Error message Error Writing to LPTx in Windows 9x. Cause

Troubleshooting common Macintosh problems

Problems with Mac OS

Print job was not sent to the printer that you wanted. Cause

Solution Software troubleshooting

Hardware troubleshooting

Problems with Mac OS

You are unable to print from a third-party USB card. Cause

Solution Software troubleshooting

General problems

Troubleshooting common PostScript problems

Specific errors

Cause Solution Font error occurred

Printer driver

Disk FAILURE. EIO X Disk not Functional

Troubleshooting the optional hard disk

Disk is Write Protected

Enww

Supplies and accessories

195

Ordering directly from HP

Ordering parts, accessories, and supplies

Ordering through service or support providers

To order directly through the embedded Web server

Ordering parts, accessories, and supplies

Part numbers

Paper-handling accessories

Description Part number

Print cartridges

Maintenance kits

Memory

Cables and interfaces

Print media

Q2397A/Asia-Pacific countries

HP Multipurpose paper

Sheets/ream, 10-ream Carton Letter 8.5 x 11 inch, 3-hole

Enww

Control panel menus

205

Print Stored JOB

Retrieve Job menu

List

Values

Username Jobname ALL Private Jobs No Stored Jobs

Information menu

Paper Handling menu

Postcard JIS

Tray 1 Size ANY Size Letter Legal Executive Statement

Executive JIS

Envelope

B5 ISO

Tray 2 Size Letter Legal Executive

64 g/m2

Tray N Size Letter Legal

Dimension

SIZE= 8.50 x 14 INCHES, Setting saved

Tray N Custom

Printing submenu

Configure Device menu

Copies

Paper Size Legal Executive Statement 8.5 x B5 JIS

DEFAULT*LETTER

Item Values

Duplex OFF Long Edge Binding Short Edge

Values

Print Quality submenu

SET Print Test Registration Source Adjust Tray N

Optimize High Transfer Line Detail Restore Optimize

Configures the fuser mode associated with each paper type

Prores

Resolution

Fastres

RET OFF Light Medium Dark Economode

Toner

System Setup submenu

Density Small Paper Mode *NORMAL Slow

To 5 *3

DATE/TIME Date Date Format Time Time Format JOB Storage

To 100 *32

Tray Behavior Sleep Delay

Display

Stapler/stacker submenu

Cartridge Stop OUT Continue JAM Recovery Auto OFF RAM Disk

LANGUAGE*ENGLISH Several Explanation

Seconds

Submenu

Staples None ONE Staples OUT Stop Continue

Parallel High Speed Input Advanced Functions

Resets submenu

Restore Factory Settings

Clear Maintenance Message Sleep Mode

Print Event LOG Show Event Paper Path Test

Diagnostics menu

Print Test Source Destination Duplex Copies

Service menu

Enww

Product dimensions, with all doors and trays fully opened

HP LaserJet 4250 or 4350 series physical specifications

Product dimensions

Printer accessories

Appendix C Specifications

Specification Volt models

Electrical specifications

Power requirements HP LaserJet 4250 or 4350 series

Product model Printing Ready Sleep Off

Acoustic emissions

Sound power level Declared per ISO

Sound pressure level Declared per ISO

Operating environment

Environmental condition Printing Storage/standby

Category Specifications

Paper specifications

Printing and paper storage environment

Envelopes

Envelope margins

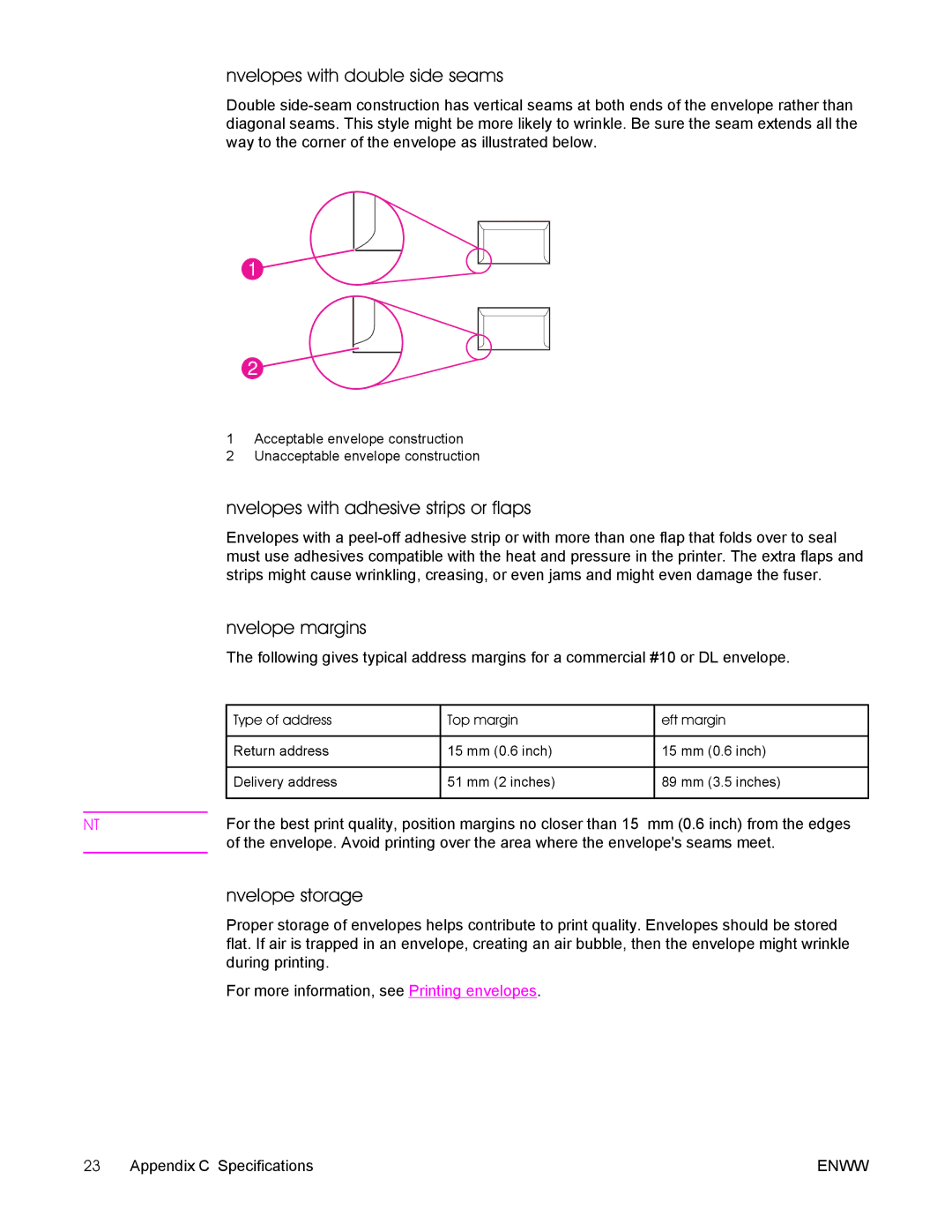

Envelopes with double side seams

Envelopes with adhesive strips or flaps

Envelope storage

Transparencies

Labels

Label construction

Enww

Printer memory and expansion

241

Overview

To install printer memory

Printer memory

Enww

Enww

Installing CompactFlash cards

To install a CompactFlash card

Installing CompactFlash cards

Enww

Checking memory installation

Saving resources permanent resources

Installing EIO cards or mass storage devices

To install EIO cards or mass storage devices

Enww

Printer commands

253

Understanding PCL 6 and PCL 5e printer command syntax

Combining escape sequences

Selecting PCL 6 and PCL 5 fonts

Using escape characters

DOS program Entry What appears

Page-control commands

Common PCL 6 and PCL 5 printer commands

Job-control commands

Function Command Options #

Function Command Options # Vertical position rows A#R

Cursor Positioning

Programming hints

Language selection

Font selection

Enww

Regulatory information

Introduction

FCC regulations

Ozone production

Environmental Product Stewardship program

Protecting the environment

Energy consumption

Material safety data sheet

Paper Material restrictions

For more information

Declaration of conformity

Regulatory Model Number3

Canadian DOC statement

Country-/region-specific safety statements

Laser safety statement

Japanese Vcci statement Korean EMI statement

Finnish laser statement

Laserturvallisuus Luokan 1 Laserlaite Klass 1 Laser Apparat

Service and support

Hewlett-Packard limited warranty statement

Appendix G Service and support

Print Cartridge Limited Warranty Statement

Onsite service agreements

Availability of support and service

HP maintenance agreements

Priority Onsite Service

HP Express Exchange U.S. and Canada only

To use HP Express Exchange

Repacking the printer

To repack the printer

What are YOU SENDING?

Service information form

WHO is Returning the EQUIPMENT?

Have YOU Removed the Print CARTRIDGE?

Enww

Index

PCL

Enww

Energy Star

Enww

Enww

283

See also drivers

256 PostScript error pages

Enww

Enww

288

Unix

Enww

Page

Q5400-90933

![]()