Setup Manual

NT631 and NT631C Programmable Terminals

Page

Omron Product References

Page

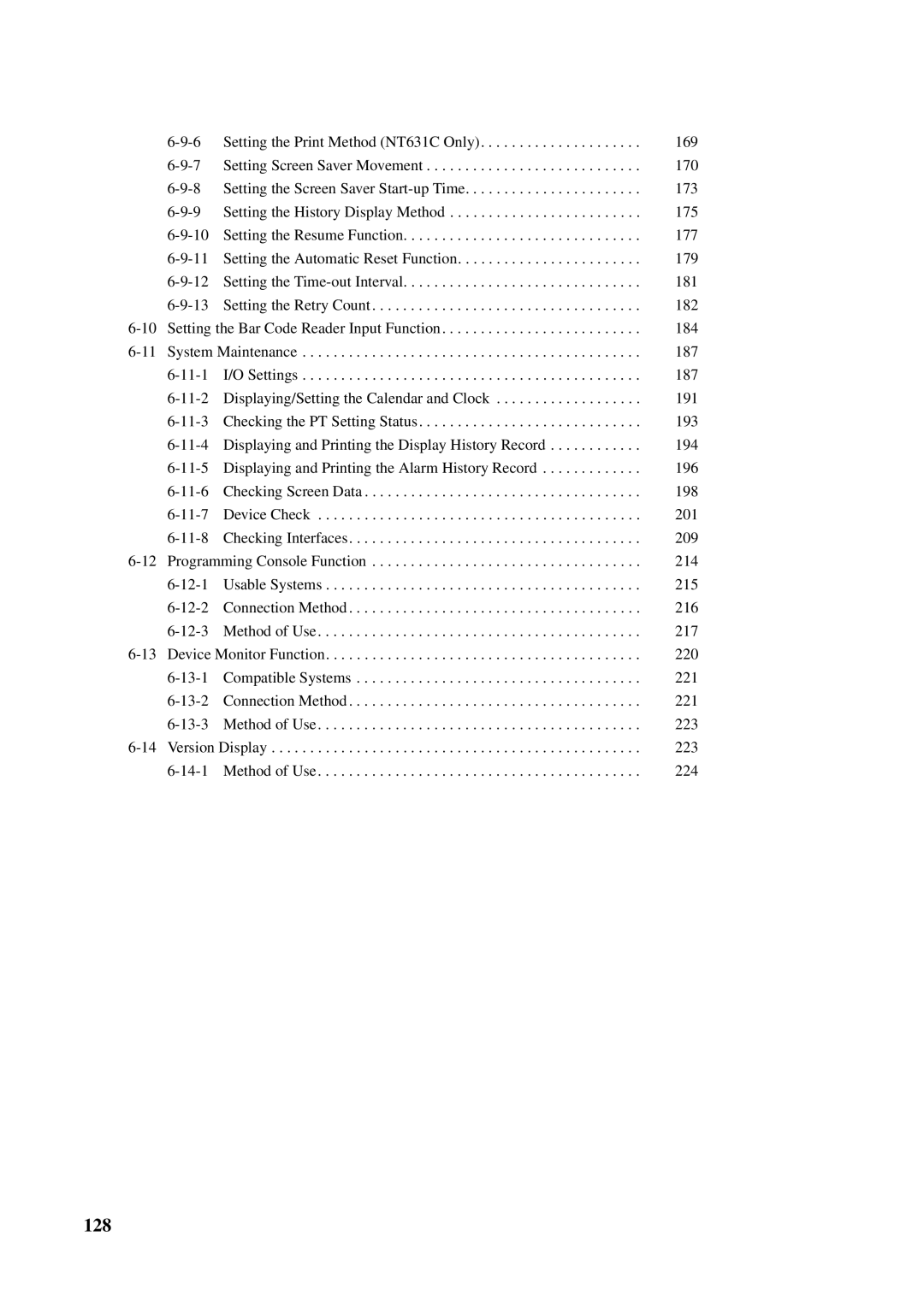

Table of Contents

Index 291 Revision History 295

About this Manual

Connecting to Controllers Not Made by Omron

Connecting and Setting Up the Programmable Terminal

Programmable Terminal Functions and Operation

Read and Understand this Manual

Application Considerations

Disclaimers

Xiv

Precautions

Safety Precautions

General Precautions

Intended Audience

Conventions used and their meanings are presented below

Safety Precautions

Xviii

Section

Role and Operation of the NT631/NT631C

Panel Switch Functions

Operation of an NT631/NT631C at an FA Production Site

Mitted to the host

Displays Screens

Operations of the NT631/NT631C

Receives Data from a Host

Sends Data to a Host

NT631/NT631C has the following features

Features

Functions of the NT631/NT631C

Section

Section

Comparison between NT631 and NT631C

NT631C

Comparison between NT620S/NT620C/NT625C and NT631

NT620S/NT620C/NT625C NT631/NT631C

NT-ZJCAT1-EV4

Data areas listed below can be accessed

Following are the principal functions of the NT631/NT631C

Principal Functions of NT631/NT631C

Numeral/character string setting function

Input by touch switches

System program install function

Screen display history function/alarm history function

Fixed Displays

Displays

Lamps

Touch Switches

Normal Standard Lamps

Image/Library Lamps

Numeral Display String Display Numeral Input String Input

Graphs

Thumbwheel Switches

Bar graphs

Analogue meter

Alarm List/History

System Configuration

Alarm List

Alarm History

Host

Peripheral Devices That Can Be Connected

Communications with the Host

Connecting to the Host

Direct Connection Function

Serial Port a

Host Link NT Link

Features of the Direct Connection Function

Section

Connecting to Other Companies’ PLCs

Communications Using Memory Links

Memory Link

Compatible PLC

Memory Link Online Transfer Function

Comparison between Direct Connection and Memory Link

Device or Software Manual Title Manual Number

Before Operating

Sysmac CPM1/CPM1A/CAM2A/CPM2C/SRM1-V2

Preparing for Connection

Communications Methods That Can Be Used with the Host

Method for Connection to the Host

NT631/NT631C and the host are indicated in the table below

Combinations of Communications Method and Connection Method

Connection possible ⋅ Connection not possible

RS-422A RS-232C Connection via a convertor unit

1N connection

RS-485 Direct 11 connection

Names and Functions of Parts

Power LED

Front View

Reference The NT631/NT631C comes in two body colors

Rear View

Hardware Settings and Connections

Installation Environment

Installation

Installation in the Operation Panel

Power Supply Connection

Applicable power supply specifications are as follows

Power Supply

Grounding

Parts Used for Connection

Recommended Connector Cable

Connecting to the Support Tool

Communications Conditions

Connecting a Bar Code Reader

Connecting a Printer

Connection Method

Reference

Possible Settings Default Setting

Setting a Bar Code Reader

Possible Settings

EVEN, ODD, None

About RS/CS Control

Data Format

STX

ETX

PT Model Function of Memory Unit

Using a Memory Unit

DIP Switch Functions

Installation Method

Switch Function

Method of Use

Method of Execution

SW2

SW2-4 on System/Screen transmitted simultaneously

Reference Reading and Writing Data by Manual Transmission

Current PT Screen Data, Screen

Current PT Screen Data, System

Current Memory Unit Screen Data

Errors When Using a Memory Unit

Source Destination

Error Probable Cause Remedial Action

Connecting to the Host from the RS-232C Port

Host Types and Settings

Connecting to the RS-232C Port at the Host

When Using the Host Link Method Compatible Host Units

CPM1

C20HE-CPU42-ZE

+CPM1-CIF01

CPM2A

Switch Setting

Connecting to a C-series Host Link Unit Settings at The Host

CTS

Setting the Rear Switches

Supply

Setting at Host

CPU Bus Unit Settings

CV500-CPU01-EV1/CV1000-CPU01-EV1/CV2000-CPU01-EV1

PLC Setup

CQM1H

PLC model Connection method

CPM2A, SRM1

Word # Writing Value Settings

PLC Setup Area Settings

Connecting to a CPM2C

When using a CPM1

Port connecting to PT PLC Setup

Setting the Switches of a CPM2C

Setting the Switches of a CPM2A

Setting the Switches on a RS-232C Adapter

CS/CJ-series CPU Unit CS1G/H-CPU@@-EV1, CS1G/H/D-CPU@@H

Using the CPU Unit’s Peripheral Port

Allocation DM Area Settings for CPU Unit

Connecting to CS-series Serial Communications Board

Setting the Front-panel Switches

Allocation DM area words Writing Value Settings Port

Allocation DM area CH Writing Value Settings Port

When Using the NT Link 11 Method Compatible Host Units

CQM1H-CPU61

CQM1H-CPU51

Host Model Word # Writing Value Setting

Setting methods for each Unit are as follows

HG/HE-ZE, CPM2A, CPM2C CQM1, CQM1H, SRM1

CPM2C-CN111 CPM2C

Setting the Switches on an RS-232C Adapter

Using the NT Link 1N Method

Connecting to CVM1/CV Series -EV@

Set the DIP switches on the front panel as follows

CS Series CS1G-CPU42/43/44/45-EV1 CS1G-CPU42/43/44/45-EV1 *1

Connection to Word # Writing Setting

Setting the DIP Switches of a C200HX/HG/HE-ZE

Using the CPU Units Built-in RS-232C Port

Connecting to CS/CJ-series Serial Communications Unit

CPU Unit Allocation DM Area Settings

Allocated DM Area words Setting Setting Contents Port

Settings required for each Unit are described below

Using the High-speed NT Link 1N Method

Connecting CS/CJ-series CPU Units

Word # Setting Setting Contents

Connecting to a CS-series Serial Communications Board

Connecting to a CS/CJ-series Serial Communications Unit

When Using the Memory Link Method

Connecting Directly between RS-232C Ports

Settings at the host

Word m = DM30000 + 100 ⋅ unit number

Model Cable Length Connector Specification

Omron Cables with Connectors

Check the required components and prepare them in advance

Name Model Remarks Delivered with

Wiring for Other Connections

Wiring for a Host Link Unit 25-pin Connection

Serial Port A, B

NT631/NT631C PLC Host link unit

Wiring for a Memory Link Connection

Pin type Host side

Section

Connecting to the Host from the RS-422A/485 Port

Connecting to the Host’s RS-232C Port

Settings at the RS-232C RS-422A Adapter NT AL001

Type of Host and Settings

Method Reference

Example the terminal resistor is active RS-422A, NT Link 1N

Connecting an NT631/NT631C and NT-AL001 RS-485

Connecting an NT631/NT631C and NT-AL001 RS-422A

Connecting an NT-AL001 and Host

Wiring for Connections Other Than Memory Link

Wiring When Connecting a Host Link Unit 25-pin

CVM1-CPU01-EV2CVM1-CPU11-EV2 CVM1-CPU21-EV2

C200HX-CPU65-ZEC200HX-CPU85-ZE

C200HX/HG/HE-ZE

Connecting an NT631/ NT631C and NT-AL001RS

Connecting an NT631/ NT631C and NT-AL001 RS-422A

Connection between NT631/NT631C Units RS- 422A

Connection between NT631/NT631C Units RS

Connectors and Cables Recommended for RS-232C

Recommended Connectors, Cables, and Crimp Terminals

C200HX/HG/HE-ZE

Cables with Connectors Made by Omron

IFVV-SB

Name Model Maker Remarks

TKVVBS4P-03

RDA

Connecting to the Host’s RS-422A/485 Port

RS-485 cable Max. total length 500 m

Standard or high-speed

C200HE-ZE

Below

C200HG-ZE

C200HX-ZE

CVM1-CPU11-EV2 CVM1-CPU21-EV2 SRM1

Instruction level, parity, and transfer code SW4

Port selection selector switch Set this to RS-422A

Port selection selector switch Set this to RS-422A Supply

100

Connecting to a CPU Unit CVM1/CV-series -EV@ CPU Units

DIP SW4

C200HX/HG/HE-ZE, CPM1, CPM2A, CPM2C, CQM1H, or SRM1

When using a CQM1H

When using a CPM1, CPM2A, CPM2C, SRM1

Setting Switches on a CQM1H Serial Communications Board

Setting Switches on a C200HX/HG/HE-ZE Communications Board

Setting the Switches on an RS-422A Adapter

DM Area Allocation Settings

Serial Communications Board Switch Settings

Allocated DM Setting Setting Contents

Allocated DM Area Setting Setting Contents Words Port

Using the NT Link 11 Method

= DM 30000 + 100 ⋅ unit number

Host Model Word # Setting Setting Contents

Connecting to a C-series C200HX/HG/HE-ZE

108

Series C200HX/HG/HE-ZE

Connection to Word # Setting Setting Contents

CPU Units with CPU Unit that becomes Model Name

110

111

112

Port DM32010 8200 1N NT Link Mode

Allocated DM Area Setting Setting Contents

114

Direct Connection between RS-422A Ports at Both Units

Connecting an NT631/NT631C and Host RS-422A

Connect to the PLC through a CPM1-CIF11 RS-422A Adapter

Wiring When Connecting CPM1, CPM2A, CPM2C, or SRM1

CS1W-SCU31-V1

CVM1-CPU01-EV@CVM1-CPU11-EV@ CVM1-CPU21-EV@

Wiring When Connecting a CVM1/CV-series CPU Unit

Direct Connection between RS-485 Ports at Both Units

Connecting an NT631/NT631C and Host

4 1N Connection among RS-422A Ports

Connecting an NT631/NT631C and a Host

Connecting between NT631/NT631C Units

C200HX-CPU65-ZE/85-ZE CQM1H-CPU51/61

5 1N Connection among RS-485 Ports

Connecting an NT631/ NT631C and a Host

Connectors and Cables Recommended for RS-422A/485

Recommended Connectors, Cables and Crimp Terminals

For M3.5

Examples of Applicable Terminals

For M3

Preparing the Shield of RS-422A/485 Connectors

Connecting the Ground Wire

Handling the Shield on RS-422A/485 Cables

Terminals

Example of Recommended Wiring

System Menu Operation

128

Starting the NT631/NT631C

System Menu Operation Flow

Operation at Startup

Initial Processing

Relationships among Modes

Operation Modes and the System Menu

Menu Item Function

RUN Mode

Menu Tree

Functions of the System Installer Mode

PLC, CPM1, CPM2A, CPM2C, CQM1, CQM1H, C200HX/HG

System Menu Memory INIT. Menu

Operations with the System Menu

Pressing a Touch Switch That Displays The System Menu

Reference Calling the System Installer Mode

Touching The Corners of The Touch Panel

Selecting Menu Items

Memory Initialization

Press Maintenance Mode

Clearing Screen Data

Select Maintenance Mode

Initializing Display History Record Data

Initializing Alarm History Record Data

139

System Menu shown below

Initializing the Recipe Tables

Menu shown below

Initializing the Memory Tables

142

Initializing the Memory Switches

Setting the Display Language in the System Installer Mode

Operations in the System Installer Mode

Memory Switch Status

OFF

Clearing/Installing the System Program

Clearing the System Program Downloading the System Program

Select Run System

Disabling/enabling System Menu Display

Changing the System Settings

Disabling/enabling Writing to The Screen Data Memory

148

Transmitting the Screen Data

150

Precautions to Be Observed When Transmitting Screen Data

Select Transmit Mode Select Tool Transmit

About Communications Conditions

Communications Condition Settings for The Host Link Method

Port Communications Method/Communications Type Settings

Communications Condition Settings for The NT Link 11 Method

No further communications conditions need to be set

Possible Combinations Communications Method Settings

Select Maintenance Mode Select Memory Switch

Setting the Host Link Method

156

Setting the NT Link 11 Method

Setting the NT Link 1N Method Standard/High-speed

159

Setting the Memory Link Method

161

Setting the Communications Type for Serial Port B

Starting Operation

Transmission of The Contents of Memory Tables

Display of The System Initialization Screen

Display of The Startup Screen

Memory Switch Setting Screens

Various System Settings

Memory Switch Settings

For the bar code reader, refer to

Setting the Start-up Wait Time

Setting the Buzzer Sound

Setting the Key Press Sound

167

Setting the Printer Controller

Setting the Print Method NT631C Only

Setting Screen Saver Movement

171

172

Setting the Screen Saver Start-up Time

174

Setting the History Display Method

Tem Menu shown below

Setting the Resume Function

178

Setting the Automatic Reset Function

180

Setting the Time-out Interval

Comm. Auto-return on

Setting the Retry Count

Comm. Auto-return OFF

Shown below

Communications Condition Settings for Bar Code Readers

Setting the Bar Code Reader Input Function

Default factory setting

Setting Communications Conditions and Setting Method

186

11-1 I/O Settings

System Maintenance

Contrast Adjustment for NT631C-ST141@-EV1 only

Setting from the System Menu

Decrease 10 steps

189

190

Displaying/Setting the Calendar and Clock

192

Display Contents

Checking the PT Setting Status

Display Contents of The First Screen

Display Contents of The Second Screen

Display Method

Displaying and Printing the Display History Record

195

Example Print-out

Displaying and Printing the Alarm History Record

Sort by occurrence, from oldest record

YY/MM/DD Hhmm

197

Sort by occurrence method, from oldest record

Checking Screen Data

YY/MM/DD

Operations On The Screen Data Check Screen

Specifying The Display Method

ON, OFF

Displaying the Screen Data Check Screen

Select Maintenance Mode Select Screen Data Disp

Device Check

Backlight Screen data memory Touch switches Battery voltage

Checking the Buzzer

Buzzer Sound memory switch

Check if the buzzer sounds correctly

203

Checking the Backlight for NT631C only

Checking the LCD Screen Display

Screen Data Memory

Touch switch is displayed in reverse video

Check if the screen data memory is functioning normally

Check

206

207

Reference Checking the Battery Voltage

Checking Communications with the Support Tool

Checking Interfaces

Check Screen

Checking Communications at Serial Ports

For Host Link

For Memory Link

For NT Link 11, 1N Standard, or 1N High-speed

For a Bar Code Reader

Check Method

Select Maintenance Mode Select I/O Check Select I/F Check

Checking Communications with a Printer

Programming Console Function

Communica Applicable PLCs Connected Port Tions Method

Usable Systems

HG/HE-ZE, or SRM1

CQM1, CQM1H, C200HX

CPM1 or CPM2A

CS/CJ-series PLC

Mode lock key, which prevents unintended mode changes

Key Operations Mode Selection Keys, Mode Lock Key

Touch panel to display the System Menu

During Lock on

During Lock OFF

Programming Console Keyboard

219

Device Monitor Function

CQM1H or C200HX/HG/ HE-ZE CQM1 or C200HS

Compatible Systems

Communications PLC model Method

Adapter or CPM1-CIF11RS-422A Adapter

CPM1, CPM2A, or SRM1

232C Adapter, or a CPM1-CIF11RS-422A Adapter

Method is exactly the same as for the 1N NT Link

Version Display

224

Troubleshooting and Maintenance

NT631/NT631C Cause Remedy Symptoms

Troubleshooting

Remedy indicated in the table

Do not disassemble the PT for repair or modification

Omron

Programming Console Function

228

Errors Occurring at Start of Operation and Their Remedies

Responding to Displayed Error Messages

Nance Mode

Message Cause Remedy

Menu

Erly referring to Replacing the Backlight

NT631/NT631C and their remedies

Errors Occurring during Operation and Their Remedies

NT631/NT631C, and the remedies for these errors

Errors in the System Installer Mode and Their Remedies

Dies

Parity error at serial port a

Communications Errors and Their Remedies

Receive Errors

Error Details Displayed Probable Cause Remedy

Send Errors

Probable Causes and Remedies

Guide to Backlight Replacement

Maintenance of the NT631/NT631C

Spare PT Backlight for NT631C- ST141@-EV2/ST151@-EV2 only

Replaceable Backlight Model

Replacing the Backlight

Procedure

Fitting The Touch Panel Cable

238

NT631C-CFL02 for NT631C-ST141@-EV2

240

Battery Type

Replacing the Battery

Guide to Replacement

Battery Replacement Method

Cleaning Method

Inspection and Cleaning

Remove them during cleaning

Used in its optimum condition

Items Required for The Inspection

Inspection Method

Points Inspected

244

Appendix a

Specifications General Specifications

Appendix a

Display Specifications

Performance Specifications

RUN

External Interface Specifications

Panel Specifications

Specification

Specifications

Special Features

Programming Environment

EIA RS-232C

Communications Specifications For a Host Link, RS-232C

For an NT Link, 11, RS-232C

For a Host Link, RS-422A

For an NT Link, 11, RS-422A

For an NT Link, 1N, RS-232C

For a High-speed NT Link, 1N, RS-232C

For an NT Link, 1N, RS-422A/485

For a High-speed NT Link, 1N, RS-422A/485

For a Memory Link, RS-232C

For a Bar Code Reader

For a Memory Link, RS-422A

RS/CS

254

Body

Dimensions

Mounting Dimensions

Cable Connection Dimensions with NT-MF261

258

Methods for Mounting and Removal

Using an RS-232C/RS-422A Adapter Dimensions

Mounting to a DIN Rail

Mounting to an Operation Panel

Removal from a DIN Rail

DIP Switch Settings

Specifications

262

CSB and CSA signals are for specialized applications

RS-232C Connector

Pin Arrangement

RS-422A/485 Terminal Block

Block Diagram

Transporting and Storing the NT631/NT631C

Appendix D

Appendix D

Cable with Shielding Wire Not Connected to FG

Cable with Shielding Wire Connected to FG

Making the Cable

Cable Preparation

Soldering

Assemble the connector hood as shown below

Hood Assembly

270

Assembly of Connecting Cables

Making the Cable for Connecting a PLC

Pin Connector

Name Model Remarks

Appendix F

Connector and Related Parts

Wiring Method

Making the Cable for Connection to a Bar Code Reader

Appendix G

Making the Cable for Connection to a Printer

Appendix H

Appendix H

Model History System program

Relationship between system program Hardware

NT-ZJCMX1-EV2

NT-ZJCMX1-EV3

Combining a -EV1 Version and -EV2 Version

Combining a -EV1 Version and Version without a -EV@Suffix

Combining a -EV2 Version and Version without a -EV@Suffix

Appendix

Host Link Units

Model List PTs

CompoBus/S Master Control Unit

Communications Unit

CPU Units for Connection via a Host Link

Model Specification PLC Type

C200HX-CPU65-ZE C200HX-CPU85-ZE

CQM1-CPU41-EV1

CPU Units for Connection via a 11 NT Link

CQM1H-CPU51 CQM1H-CPU61

CPU Units for Connection via a High-speed NT Link 1N

CPU Units for Connection via a 1N NT Link

RS-232C/RS-422A Adapter

Cables with Connectors for PT ↔ PLC/NT-AL001

RS-232C Adaptor, RS-422A Adaptor

Related Parts and Equipment for PT

Connecting Cable for the CPM2C Communications Connector

Applicable Connectors

Connection Cable

Printer Cable

Option List

Appendix K

This is a lithium battery used for memory backup

Replacement Battery .. G2A9-BAT08

Chemical-resistant Cover ... NT625-KBA01

Protects against Does not protect against

Memory Unit ... NT-MF261

290

Numerics

Index

293

294

Cat. No. V063-E1-03 Revision code

Revision History

Revision History

Terms and Conditions of Sale

Omron Electronics LLC