Product overview

Sitrans P Accessories

Transmitters for gage, absolute

Differential pressure

Overview

Product overview

Sitrans P measuring instruments for pressure

Transmitters for gage, absolute and differential pressure

Mode of operation

Series for gage pressure

Dimensional drawings

Technical specifications

Schematics

Series for gage and absolute pressure

Accuracy

Power supply UH

Rated operating conditions

������

Mbar g psi g1

With metal measuring cell

Up to Bar psi g1

For absolute pressure

Measuring range

Output signal

Measuring ranges for absolute pressure only for US market

Explosion protection

Process connection

Sealing material between sensor and housing

C11

E10

Technische Daten

Sitrans P250 for differential pressure

Sitrans P250 differential pressure transmitter Application

Certificates and approvals Approval

Conditions of use

Connection 1 +UB

Mm inch Inch mm

Width across Flats

Female thread G1/8 Stainless steel 1.4305/AISI

Male thread G1/8-a = CuZn nickel-plated

Sealing material

Accuracy ≤ 1 %, wetted parts ceramic/stainless steel

Available ex stock Siemens FI 01 ·

Functions

ZD series for gage and absolute pressure

Displays and controls

Power supply

Type a

Input variable

Series for gage and absolute pressure

Measured range Span

Selection and Ordering data Order Code

Overview Application

Sitrans P Compact For gage and absolute pressure

Transmitters for food, pharmaceuticals and biotechnology

Filling liquid

Diaphragm seal With quick-release clamp

Sitrans P Compact pressure trans

Diaphragm seal With aseptic connection

Measured range Overload pres Sure

Measured range Overload pressure

Hygiene version P01

Integral cooling element K01

Clamp-on seal With aseptic connection

ISO pipes to ISO

Measured range

Sitrans P, dimensions in mm inch

Dimensional drawings Housing

Sitrans P Compact, connection diagram Siemens FI 01 ·

Gage pressure

Sitrans P300 for gage and absolute pressure

Level

Absolute pressure

Design Function Device comprises

Function diagram of electronics

Operation of the electronics with Hart communication

Electronics

Operation of the electronics with Profibus PA communica

Mode of operation of the measuring cells

Tion Electronics

Measuring cell for absolute pressure, function chart

Measuring cell for gage pressure, function chart

Parameterization of Sitrans P300

Physical variable Physical dimensions

Parameters Input keys Hart com Munication

Fieldbus interface

Parameters Input keys Profibus PA

Profibus PA and Foundation Fieldbus

Sitrans P300 for gage pressure and absolute pressure

Gage pressure input

Absolute pressure input

≤ 0,2% ≤ 0,4% 30 r ≤ ≤ 0.005 ⋅ r + 0.05%

≤ 0,1% ≤ 0,2% 10 r ≤

≤ 0.2 ⋅ r + ≤ 0.25%/10 K ≤ 0.5% 140 .. F

With front-flush diaphragm

Design standard version

+150 C

Design version with front-flush dia Phragm

Transmitters for food, pharmaceuticals and biotechnology

Profibus PA communication

Hart communication

Communication Foundation Fieldbus

20 mA/HART

Selection and Ordering data Order No

Foundation Fieldbus FF

Measuring cell filling

Seal diaphragm Measuring cell Stainless steel

Foundation Fieldbus FF F 8 1 2

See Further designs

Stainless steel, deep-drawn and electrolytically Polished

Temperature decoupler up to 250 C P10

Temperature decoupler up to 200 C7 P00

Mounting bracket A02

Cable socket for M12 plug

Preset bus address Y25

Setting of pressure indication in pressure Y21 Units

Q63

Q64

Sitrans P300, with oval flange, dimensions in mm inch

Sitrans P300, front-flush, dimensions in mm inch

NuG and pharmaceutical connections

Flanges to EN and Asme

Tank connection TG52/50 und TG52/150

Thread connection G¾, G1 and G2 to DIN

IDF socket with union nut

Aseptic flange with notch to DIN 11864-2 Form a

Sitrans P, DS III series

Transmitters for gage pressure for the paper industry

Device front view, Sitrans P DS

Transmitters for gage pressure for the paper industry

Function

Parameterization

Measuring cell for gage pressure with front-flush diaphragm

Adjustable parameters Input keys Profibus PA

Pressure setting can also be

Temperature F, R Miscellaneous Siemens FI 01 ·

Lmp, gallon, bushel, barrel, barrel

Signal

Output signal 20 mA

DS III series with PMC connection

Profibus PA or Foundation Fieldbus

To EN 61326 and Namur NE Munity

Transmitters for gage pressure for the paper industry

Analog input Adaptation to customer-specif

Measuring cell filling Cleaning

Series DS III Hart Measuring cell filling Cleaning

Nominal measuring range

Electrical connection / cable inlet

B11

M12 cable sockets metal A50 Rating plate inscription

C11 Bration to IEC Acceptance test certificate C12

P02

40.9 mm Approx 36.8 mm

PMC Style standard

PMC Style minibolt

26.3 mm Approx 33.1 mm

To EN 61326 and Namur NE Siemens FI 01 ·

Sitrans P300 with PMC connection

Transmitters for gage pressure for the paper industry

Hart communication 230 .. Ω Protocol

Reset function due to metering

Bytes

Perature Simulation function Available

Y22 + Sure units Y01

40.4 mm Approx 36.8 mm

DS III, DS III PA and DS III FF series Technical description

Front view

Pressure transmitter for gage pressure

Function diagram of the electronics

Measuring cell for gage pressure

Measuring cell for gage pressure, function diagram

Measuring cell for level, function diagram

Parameters Input keys Hart com

Parameterization DS

MmH2O, ftH2O 20 C, inHg, mmHg

G/min, g/s, lb/d, lb/h, lb/min, lb/s

Temperature F, R Miscellaneous Siemens FI 01 ·

DS III series For gage pressure

Sitrans P, DS III series for gage pressure

T4...T6 CL II, DIV 2, GP FG CL Siemens FI 01 ·

Classification according to pressure equip

Internal preprocessing Device profile

Silicone oil Standard Inert liquid1 Grease-free

Display Without indicator

Bar g 15 .. .5 psi g Psi g 102.0 ...10153 psi g

EEx ia + EEx d6 Ex nA/nL zone

Screwed gland M20x1.5 Screwed gland ½-14 NPT Plug M12 metal6

EEx ia + EEx d5 Ex nA/nL zone

Explosion-proof Intrinsic safety to E25 Inmetro Brazil

Digital indicator alongside the input keys D27

Explosion-proof Intrinsic safety to E55 Nepsi China

Setting of pressure indication Y22 + Non-pressure units Y01

Dimensional drawings

Sitrans P measuring instruments for pressure

Input absolute pressure, with front-flush Diaphragm

10 ... +85 C 14 ... +185 F

Weight without options ≈ 1.5 kg ≈ 3.3 lb Housing material

40 ... +150 C -40 ... +302 F

40 ... +200 C -40 ... +392 F

Ehedg

Hart communication

Seal diaphragm Connection shank Stainless steel

Absolute pressure, front-flush membrane

Flange version with Order code M.., N.., R.. or

Bar g1 Psi g1 Mbar a2 Psi a2 Bar a2

PROFIsafe certificate and protocol C21 Flanges to EN

Temperature decoupler up to 200 C4 P00

M48

M49 Threaded connection acc. to DIN Form a

Additional data

Asme B16.5 Varivent connection

115 mm Approx 100 140 mm 52 mm 150 mm 170 mm 165 mm 200 mm

300 255 mm Siemens FI 01 ·

IDF threaded socket

Tank connection TG52/50 and TG52/150

95 x 1/6 110 x ¼ 100 130 x ¼

Aseptic threaded socket to DIN 11864-1 Form a

113

133 100 159

Profibus PA or Foundation Fieldbus Input

Profibus PA or Foundation Fieldbus

Profibus PA or Foundation Fieldbus Certificate and approvals

Hart communication

Pressure, from the pressure series DS III Hart

Mbar a Psi a Bar a

Hidden, setting mA With visible digital indicator

E55 China

C11 Bration to IEC 60770-2 Acceptance test certificate2 C12

Dimensional drawings

Sitrans P measuring instruments for pressure

Technical specifications

Design

100

101

Pressure, from the differential pressure

102

Casting6

EEx ia + EEx d Ex nA/nL zone

Casting

103

104

Sealing screw with valve option

105

106

107

DS III series for differential pressure and flow

464 psi InH 2O Mbar 160 bar

108

Weight without options ≈ 4.5 kg ≈ 9.9 lb Housing material

Wetted parts materials Seal diaphragm

109

Profibus PA or Foundation Fieldbus Power supply UH

Graph 3 sound engineering practice PN 420 MWP 6092 psi

110

111

112

PN 32/160 MWP 464/2320 psi Measuring cell filling Cleaning

Tial pressure and flow, Series DS III Hart

PN 32 MWP 464 psi Mbar2 4015 .. .03 inH2O

113

Zone 2 planned Intrinsic safety, explosion-proof enclosure

PN 32 MWP 464 psi Mbar2 03 inH2O

Wetted parts materials stainless steel process flanges

114

115

Setting of pressure indicator in pressure Y21 Units

Y02

Y221 Non-pressure units

Silicone oil Standard

116

PN 420 MWP 6092 psi Display

117

Explosion-proof Zone 2 to Nepsi China E57

118

Max digits Y02 Up to Mbar, bar, kPa, MPa, psi

Y22 + Non-pressure units Y01 or

119

120

121

Process connection ¼-18 NPT EN 61 Blanking plug

122

123

124

DS III series for level

Sitrans P, DS III series for level

To EN 61326 and Namur NE Nity

125

Yes Siemens FI 01 ·

Classification according to pressure equipment

126

Mounting flange

127

Process connection of low-pressure side

128

Rings for process flanges on Low-pressure side

129

A31 Sealing screws

Use on zone 1D / 2D E01

Y221 Non-pressure units + Y01

130

Mounting flange F 4 9 1

Tube length

Flame flashover lock-out A01

131

Tation

= available

Nom. diam Nom. press

132

200 138 160 150 or 220 115 158 180 235 162 190

200 138 721 160 150 or 220 115 158 180 235 162 190

133

Supplementary electronics for 4-wire connection

Sitrans P Accessories

134

Structural design

135

Supplementary electronics for 4-wire Connection

Output current

E86060-K6017

136

A23 Acceptance test certificate C12

137

Process connection G½A D16 Remote seal flanges D20

Vent on side for gas measurements H02 Process flanges

138

Replacement measuring cell for level F 4 9 9

Rated measuring range

Without process flanges K00

139

140

141

Selection and Ordering data

142

Valve manifolds mounted on Sitrans P DS

143

144

Valve manifolds mounted on Sitrans P300

145

MPS series submersible sensor

Transmitters for hydrostatic level

146

Integration

Junction box Application

147

Cable hanger Application

148

More information

149

7MF1570-5ZA02-Z

150

Remote seals for transmitters and pressure gages

Designs

Quick-release diaphragm seal

151

Temperature error

Transmission response

Miniature diaphragm seal with diaphragm flush with front

Response time

152

Recommendations

153

Technical specifications Temperature error Diaphragm seals

Inch Mbar Psi 10 K 10 K ⋅ m Kap

290 870 6000 Phragm seal G1½B 058 145 2000

Inch Mbar Psi 10 K

154

155

Temperature error Clamp-on seals

Example of temperature error calculation

Calculation of the temperature error

Dependence of temperature error on diaphragm material

Maximum temperature of medium

Filling liquid Density Temperature

Technical data of filling liquids

157

Response times

158

Diaphragm seals of sandwich design

Diaphragm seals of sandwich design

159

Connection to EN

160

Connection to Asme B16.5

161

Diaphragm seals of flange design

Diaphragm seals of flange design with flexible capillary

To a pressure transmitter Sitrans P order separately

162

Length of capillary4

163

4404/316L B16.5 RF 125 .. AA For the other materials

164

165

Nom Diam Press

166

Pressure transmitter

167

Mounting flange with tube as option for

168

Flanged remote seal without tube, fitted by

Diaphragm seal Mounting flange with tube as option for

200 138 160 DN 100 PN 158 180 235 162 190

169

Nom. Nom Diam. press

For gage, absolute and differential pressure

Quick-release diaphragm seals

170

Quick-release diaphragm seal

Connection to pressure transmitter

171

Connection to transmitter

Vacuum-proof design V03

172

0 15 ³ R

173

Miniature diaphragm seal

Miniature diaphragm seals

Vacuum-proof design V01

For diaphragm seals

Flushing rings

174

Process connection

Connection to Asme B

175

For gage pressure, differential pressure and flow

Clamp-on seals of flange design

176

Clamp-on seals for flange-mounting

Delivery 1 off

177

Class

178

Quick-release clamp-on seals

Remote seals Weight Approx kg approx .82 lb

For pressure and absolute pressure

179

For Sitrans P pressure transmitters for

180

Pressure 7MF403 7 and 7MF423 7 together with Order

Connection to DIN 11851 with screw necks

181

Clamp connection for pipes to BS 4825/3 and o.D. tubes

Remote seals

Measuring setups

182

183

Measuring setups with remote seals

184

Types of installation for level measurements closed vessels

185

Measuring setups without remote seals

186

Measuring setups for closed containers

187

Y01

188

Range

189

Values must be entered here Siemens FI 01 ·

190

Fittings

New standard DIN EN

Material acceptance test certificate to EN

191

Selection aid

Selection of available shut-off valves

Differential pressure transmit

192

201 Way valve manifolds 206

212 Tion DN 5/DN 8 for vapor Measurement 7MF9416-6

193

Shut-off valves to DIN 16270, DIN 16271 and DIN

Shut-off valve, form B, dimension drawing, dimensions in mm

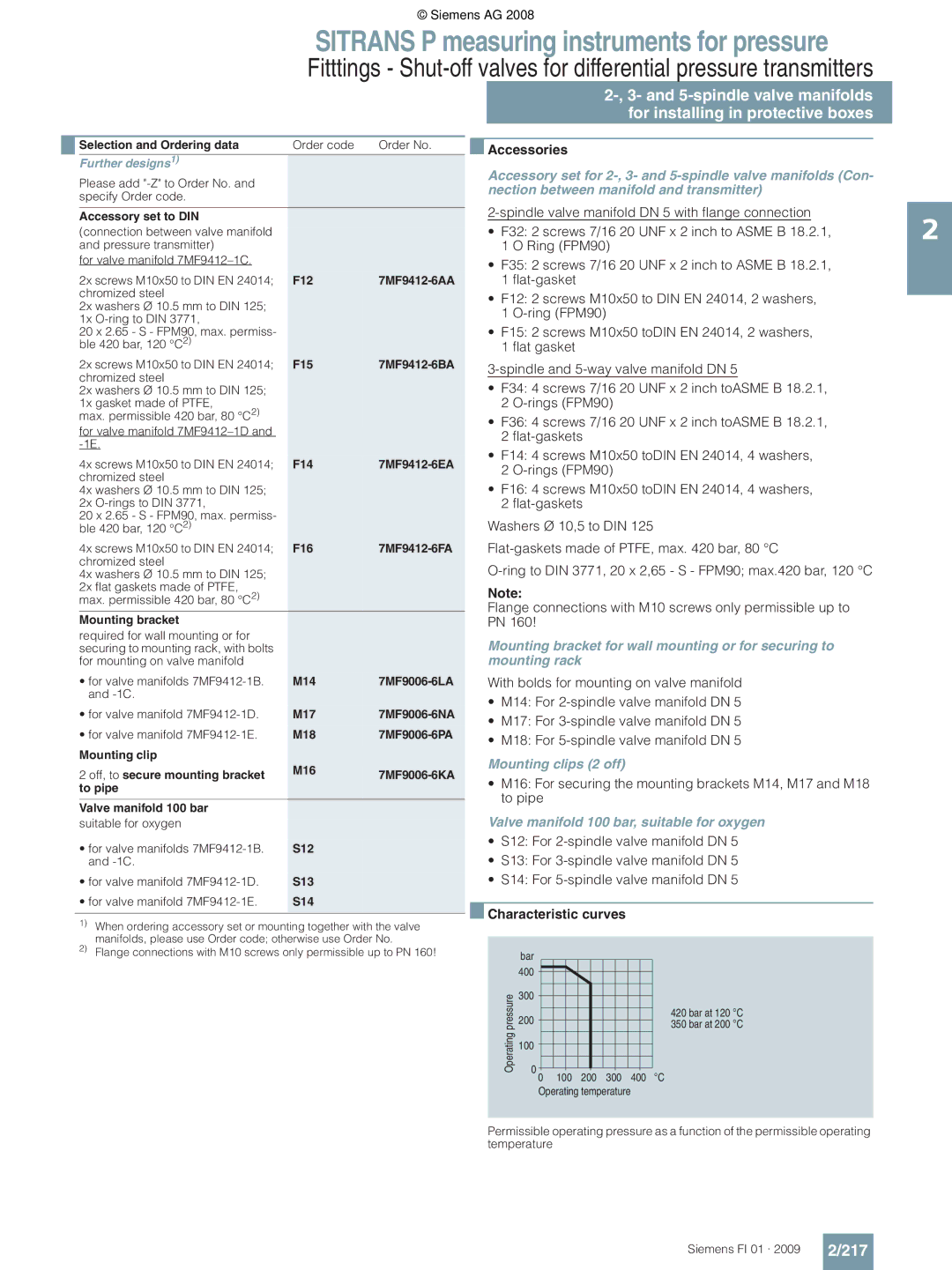

Characteristic curves

194

Angle adapter

Overview Dimensional drawings

195

Angle adapters 7MF9401-7WA

196

Double shut-off valves

197

Accessories for shut-off valves / double shut-off valves

198

Way valve manifolds DN

199

200

Connection diagram of the 2-way valve manifolds

201

5-spindle valve manifolds DN

202

203

Spindle valve manifold DN 5 7MF9411-5B., dimensions in mm

204

Multiway cocks PN

Accessory set for multiway cock PN

Accessories Dimensional drawings

205

Multiway cock in oil-free and grease-free design

206

Way and 5-way valve manifolds DN

Overview Function

For non-aggressive liquids For aggressive Gases Liquids

207

BB C

208

Way valve manifold DN

Component Material Mat. No Housing P250GH 0460 4571

209

For pipe mounting, weight 0.7 kg M12 7MF9006-6GA

Accessory set for 3-way valve manifold DN 8 for flanging

210

For wall mounting or for securing on rack 72 mm grid

211

Dimensional drawings Schematics

212

Valve manifold combination DN 5/DN

Valve manifold combination DN 5/DN 8 for Vapors

Valve manifold DN Blow-out valves DN

213

214

Valve manifold combination DN

Valve manifold Blow-out valves

Without test connection With test connection M20 ×

215

Functions

216

Mounting clips 2 off

217

218

Spindle valve manifold DN 5, connections

219

Spindle valve manifold DN 5, connections Siemens FI 01 ·

Valve manifolds for vertical differential Pressure lines

220

Mounting bracket Required for wall mounting or for

M18 7MF9006-6PA Required for mounting on 2 stand

221

Accessory set connection between manifold and transmitter

Mounting bracket for mounting on 2 standpipe

222

Low-pressure multiway cock

Accessory set for low-pressure multiway cock

223

Mounting bracket 7MF9004-6AA M13, dimensions in mm

OptionsCharacteristic curves

224

Oval flange

Fittings Accessories

225

226

Adapters, connection glands

227

Connection parts G 1/2

228

Water traps, Sealing rings to EN

Made

229

Pressure surge reducers

Pressure surge reducer

M56340-A54

Shut-off valve 7MF9017-1B. and -2B., dimensions in mm

Shut-off valve 7MF9017-1A., dimensions in mm

Primary shut-off valves

230

X b 7MF9017

231

Shut-off valve for non-aggressive liquids, gases and vapors

Shut-off valve for aggressive liquids and gases

Compensation vessel 7MF9015-5.., dimensions in mm

Compensation vessel 7MF9015-1.., dimensions in mm

Compensation vessels

232

233

Connection parts

234