! Caution

There is a risk of fire

There is a risk of accident

Failure may result

Electric shock may occur

Accident may result

Electric shock may result

Never modify the product

Treat as industrial waste when disposing it

Electrical shock may result

Electric shock or injury may result

DCR

DCR FRNF50G11S-4UX

Use the following power supply to the inverter

Tightening torque and wire range

General instructions

Contents

Type Inverter type

Before Using This Product

Receiving Inspections

Appearance

1 Removing the surface cover for inverter of 30HP or less

Handling the Product Removing the surface cover

1 Storage environment

2 Output current reduction rate based on altitude

Installation and Connection

Installation Method

1 Operating environment

Voltage Inverter type Bracket screws Case mounting

Removing the ventilating covers

Electric shock or fire may result

Always connect a ground wire

Basic Connection Diagram Sink Logic

Basic Connection Diagram to PLC Sink Logic

Gfci

THR

1 Functions of main circuit terminals and ground terminals

Connecting the main circuit and ground terminals

Main circuit power terminals L1/R, L2/S, L3/T

Inverter output terminals U, V, W

DC link circuit terminals P + and N

Auxiliary control-power input terminals R0 and T0

DC reactor connecting terminals P1 and P +

Fire may result

Frequency Hz Power voltage range VAC

Inverter ground terminal

9 Fan power switching

Cnux U1 Cnrxtx L1/R-L3/T

FWD

Connecting the control terminals

13 Example of noise prevention

Others

Wiring of control circuit inverter of 40HP or more

Digital input terminals FWD, REV, X1 to X9 and CM

Transistor output terminals Y1 to Y4, CME

L3/T L1/R L2/S

Terminal arrangement

Main circuit terminals

L2/S L3/T Screw size M4

P24 DX − DX + 30A

Control circuit terminals

30C 30B

Y5C FWD REV

FRNF50G11S-4UX

Applicable equipment and wire size for main circuit

FRNF25G11S-2UX

FRNF50G11S-2UX

108

Phase

Power supply

Auxiliary power input Supplied Magnetic contactor

Trial Run

Operation

Inspection and Preparation before Operation

Operation Method

Appearance of Keypad Panel

Keypad Panel

Keypad panel operating system during normal operation

Alarm occurrence

Keypad Panel Operation System LCD screen, Level Structure

1 Overview of contents displayed for each level

Other than digital setting

Operating Keypad Panel Operation Mode

Setting digital frequency

Digital keypad panel settings F01=0 or C30=0

Menu screen

Switching the LED monitor

Setting function data

To switch to LED monitor display When power is turned on,

Display Reason for no modification Release method

To scroll Function Select screen rapidly , use alphabet

To move the screen in a unit grouped by

Screen

Checking function data

Monitoring operating status

PRG⇒PRG Menu F/D ⇒LED Shift

Data Setting 2.DATA Check 3.OPR Mntr ⇒4.I/O Check

8 I/O check

NRK=xxxxx NRR=xxxxx NRO=xxxxx

Maintenance information

Load rate measurement

EDC=

Alarm information

TRQ=

Maintenanc 6.LOAD Fctr 7.ALM INF ⇒8.ALM Cause

Alarm history and factors

Data copy

Data protection

Change disabled during operation

Memory error

Verify error

PRG⇒PRG Menu RESET⇒RESET

Alarm mode

Alarm detection order

Alarm detection order

Name

Function select Function select list FFundamental Functions

CControl Functions of Frequency

EExtension Terminal Functions

HHigh Performance Functions

PMotor Parameters

UUser Functions

AAlternative Motor Parameters

Function code

1 The factory setting value details

FRN001G11S-4UX FRN002G11S-4UX FRN003G11S-4UX

Function Explanation

C33

Frequency setting block diagram

F05 Rated voltage

Setting range 230 V series 80 to Series

F03 Maximum frequency

F04 Base frequency

F10 Electric thermal O/L relay Select F11 Level F12

F09 Torque boost

S T

F13 Electric thermal O/L relay for breaking resistor

U59

Accident may result

F14 Restart mode after momentary power failure

Power failure

F17Gain

Setting range Inactive

F15 Frequency limiter High F16 Low

F18Bias frequency

F26 Motor sound carrier frequency

Setting range 0.0 to 60.0Hz

Voltage adjust

Setting range 0 to 200%

F34

F36 30Ry operation mode

F33

Pulse rate

Set value

Accident may result F42 Torque vector control

P01, P09 2 T R Q

Off

Frequency selected

E01 X1 Terminal function E09 X9 Terminal function

Motor selected Related function

Motor

On →off

Set value Input signal Function Off →on

Disable PID control

Torque limit Related function F41 Value selected F40

H18

Alarm

Inverse operation when forward

F14 Off

E16 Torque limiter 2 driving E17 Torque limiter 2 braking

Settings when shipped from the factory

E10 Acceleration time E11 Deceleration time E12 E13 E14 E15

E20 Y1 terminal function E24

AL4 AL8

STG1 STG2 STG4

AL1

E30 FAR function signal Hysteresis

E25 Y5 Ry operation mode

Output current

E46Language

E45 LCD monitor function

Display item

Set value

C05 Multistep frequency C19

Setting range G11S 0.00 to 400.00Hz

C01 Jump frequency C02 C03 C04 Jump frequency Hysteresis

‹Setting example 100 F

Bias -100 to +100% GAIN0.0 to 200%

C30 Frequency command

Related functions E01 to E09 Set value11 F01

C31 Bias terminal12 C32Gain terminal12

T E R

C33 Analog setting signal filter

Tuning procedure

Inactive Active

P05 Motor 1 On-line Tuning

As injury may result

Set value Operation

Retry failed

Hen retry succeeded

FWD-CM

H08 Rev. phase sequence lock

H07 ACC/DEC (Mode select) pattern

Related functions U02 to U05

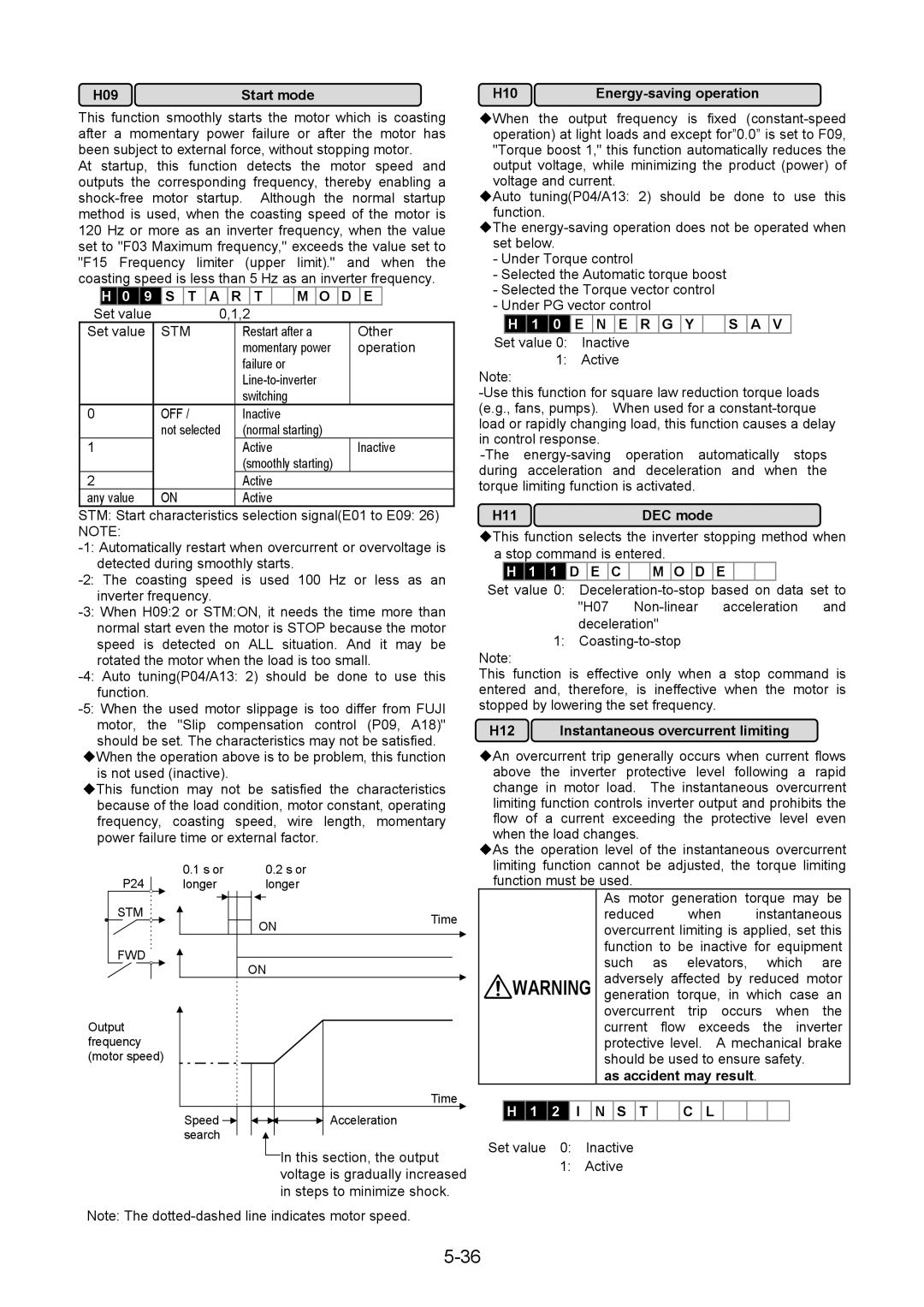

1 D E C M O D E

H09 Start mode

H11 DEC mode

H10 Energy-saving operation

Related functions

H13 Auto-restart Restart time H18 Torque control

To 5.0 seconds

‹This Function controls motor torque according to a

Set value Descriptions

H20 PID control Mode select H25 PID controlFeedback filter

H21 PID control Feedback signal

100% feedback amount

4 D G a I N

Deviation Time Operation amount

2 P G a I N

3 I G a I N

Value Inactive

Setting range 0.0 to 60.0 seconds

H26 PTC thermistor Mode select

H25 PID control Feedback filter

H39 RS-485 Response interval

Setting range 0 to Set value

H30 Serial link Function select

H31

Slippage = Synchronous speed-Rated speed

‹100% value of this function means maximum frequency fmax

Set value 15 becomes 1Hz. The set value 1 becomes 1/15Hz

U23

U15 Slip compensation filter time constant

Filter time constant of Slip compensation is set

U49 RS-485 protocol selection

U48 Input phase loss protection

U59 Braking resistor function select

Failure may result

Voltage detect gain adjustment

00 OH1 alarm at DC fan broken No alarm at DC fan broken

U61 Voltage detect offset and gain adjustment

Voltage detect offset adjustment

Motor overload memory retention

U89

List of Protective Operations

Protective Operation

Trip -2-1

Alarm Reset

Reset command

Keypad panel display Alarm display

Overcurrent

Trouble shooting

Ground fault

Protective function activation

Low voltage

Overvoltage

Overheating

Overtemperature inside air

Output wiring error

Memory error Er1

If motor does not rotate

Abnormal motor rotation

UP/DOWN

If the motor rotates but the speed does not change

If the motor generates abnormal heat

If the motor stalls during acceleration

Environment

Maintenance and Inspection

Check parts Check items How to inspect Evaluation Criteria

1 Periodical inspection list

Is there discoloration due to overheating?

Power is off Tighten

Use this function as follows

Estimate life

Page

Rectifier type

Digital Moving-iron Digital power Moving-coil

1 Meters for measuring main circuit

Meter Moving-iron

Inquiries about Products and Product Guarantee

Exclusion of Liability for Loss of Opportunity, etc

Free of Charge Warranty Period and Warranty Range

Service Contents

Applicable Scope of Service

Three-phase 230V series

Specifications

Standard Specifications

Three-phase 460V series

Transport 70 to 106 kPa

Common Specifications

Inch mm

Outline Dimensions

Outline Dimensions 30HP or less

460V Series

Outline Dimensions G11S 40HP to 350HP, P11S 40HP to 450HP

230V Series

W3 W4

Outline Dimensions G11S 400HP or more ,P11S 500HP or more

Fig図. C

Outline Dimensions Reactor Accessories for 100HP or more

Connection

Transmission Specification

Serial Interface Configuration

RS-485 Modbus RTU Serial Communications

Operation command data Registers

Inverter Function Code Access

Command and Monitor Data Registers

Frequency Setting Registers

Monitoring parameter registers

Bits binary data

Data Format Specification

Data format Index data ACC/DEC time, display coefficient

Data format Alarm Code

Data format Capacity code

Forward operation Current limiting

Inverter fault

Data format Pattern operation

All bit are on or active by

NAK

Data format Code setting 1-4 figures

Data format Type code

USA

Data format Auto tuning

Built-in Options

Options

10-1

FAB

Separately Installed Options Name Type Explanation

10-2

Motor

EMC product standard EN61800-3/1997 +A11/2000

Electromagnetic compatibility EMC

11-1

General

Filters

Recommended Installation Instructions

11-2

Applied Inverter Filter Type

11-3

Outline Dimensions RF3100-F11, RF3180-F11

Mccb

11-4

RCD or RFI filter Inverter

Harmonics restriction in Europe Union EU

11-5

2007-11 K07/K07 10CM

![]()

![]()

![]()

![]() Acceleration search

Acceleration search

M O D E

M O D E