Color Laserjet Enterprise CP4020/CP4520

Page

HP Color LaserJet Enterprise CP4020- CP4520 Series Printers

Trademark Credits

Copyright and License

Conventions used in this guide

Iv Conventions used in this guide

Table of contents

Removal and replacement

Print-quality test

119

Enww

Solve problems

265

383

Parts and diagrams

Appendix B Product specifications

Appendix a Service and support

Appendix C Regulatory information

515

Xvi

List of tables

17 Causes and solutions for fuser delivery delay jams 394

Table B-4

Enww

List of figures

49Paper-feeder pickup and feed operation

41 Remove the front-top cover 1 100

71 Remove the secondary transfer assembly 1 119

115 Remove the delivery assembly 3 146

161 Remove the tray-pickup drive assembly 1 178

209 Remove the fuser-drive assembly 1 212

19 Test the Tray 1 media-present sensor 261

20 Paper feeder external covers, panels, and doors 470

Xxx

Theory of operation

1Relationship between the main product systems

Basic operation

1Sequence of operation

Sequence of operation

Period Duration Description

2Engine-control system

Engine-control system

Solenoids

DC controller

Component abbreviation Component name

Clutches

Switches

Sensors

Sensors

Abbreviation Name Purpose Failure detection

Motors

Abbreviation Name Cooling area Type Speed

Fans

7High-voltage power supply circuits

High-voltage power supply

Circuit Description

Biases for each color

8Converted DC voltages

Low-voltage power supply

Sleep powersave mode

Safety

Low-voltage power supply failure

Overcurrent/overvoltage protection

9Fuser components

Fuser control

Type of component Abbreviation Name Function

Fuser sleeve temperature protection

Fuser temperature control

Failure detection

Fuser unit life detection

Fuser unit identification

8Laser/scanner system

Laser/scanner system

Laser/scanner failure

Protective-glass cleaners

9Protective-glass cleaners PGCs Theory of operation

ITB

Image-formation system

11Image-formation drive system

Functional block Steps Description

Image-formation process

Primary charging

Pre-exposure

Development

Laser-beam exposure

Secondary transfer

Primary transfer

Separation

Fusing

Drum cleaning

ITB cleaning

Print cartridge

23Print-cartridge system

Developing-roller engagement and disengagement

25 ITB unit

Intermediate transfer belt ITB unit

10Primary-transfer-roller engagement states

Primary-transfer-roller engagement and disengagement

SL1

Calibration

27ITB cleaning process

Image-stabilization control

Color-misregistration control

11Image-stabilization controls

29 Paper path

Pickup, feed, and delivery system

Component

Abbreviation Component

32Three main units of the pickup, feed, and delivery system

Cassette pickup

Pickup-and-feed unit

Cassette-presence detection

Top switch Center switch Bottom switch

Paper size

Cassette multiple-feed prevention

35Cassette lift mechanism

36Multiple-feed prevention

Multipurpose tray pickup

37Multipurpose tray pickup mechanism

Paper feed

38Paper-feed mechanism

Paper detection

Skew-feed prevention

14Print mode and feed speed

Fusing and delivery unit

Simplex printing

Duplex printing

40Fuser and delivery unit

Loop control

41Loop-control mechanism

42Pressure-roller pressurization control

Pressure-roller pressurization control

43Duplexing unit

Duplexing reverse and feed control

Duplex reverse and feed control

Duplex print operation

Enww

45Jam detection sensors

Jam detection

Jam Description

16Jams that the product detects

461 x 500 optional paper feeder

Optional paper feeder

473 x 500-sheet optional paper feeder

17Electrical components for the paper feeder

Motor control

Component Abbreviation Component name Type

Component Drives Failure detection

18Pickup feed components 1 x 500-sheet paper feeder

Paper-feeder pickup and feed operation

SW2 SW3 SW4

OFF

Paper-size detection and cassette-presence detection

SR2/SR8/SR9

Paper-feeder cassette lift operation

51Jam detection 1 x 500-sheet paper feeder

Paper feeder jam detection

52Jam detection 3 x 500-sheet paper feeder

Enww

Removal and replacement

Introduction

Removal and replacement strategy

Required tools

Electrostatic discharge

After performing service

Before performing service

Print-quality test

Post-service test

Parts removal order

2Parts removal order 1 Removal and replacement

3Parts removal order 2

Print cartridges

Customer self repair CSR components

5Remove the print cartridge 2

Toner-collection unit

7Remove the toner-collection unit 2 Removal and replacement

8Remove the toner-collection unit 3

ESD sensitive component

Formatter PCA

Remove the hard drive

Hard drive

Before proceeding, remove the following components

13Remove the hard drive 3 Removal and replacement

Remove the memory Dimm

Memory Dimm

Click Settings

Enable memory

Click the Device Settings tab

Next to Automatic Configuration , select Update Now

Installable Options area

Next to Automatic Configuration, select Update Now

Click the Installable Options menu

Windows

Tray

Fuser

Feed and separation rollers Trays

Pickup roller Tray

24Remove the pickup roller Tray 1 4 Removal and replacement

Enww

Secondary transfer roller

29Reinstall the transfer roller

Reinstall the transfer roller

Intermediate transfer belt ITB

32Remove the intermediate transfer belt 3

Enww

Identification and location

External panels, covers, and doors

35Remove the upper-left cover 1 Remove one screw

Upper-left cover

37Remove the upper-left cover 3

38Remove the power-supply cover Removal and replacement

Power-supply cover

Remove the left cover

Left cover

Remove the front-top cover

Front-top cover

43Remove the front-top cover 3

Remove the rear-top cover

Rear-top cover

Remove the right-front cover

Right-front cover

Reinstall the power button

Remove the control-panel assembly

Control-panel assembly

Enww

Remove the front-door assembly

Front-door assembly

53Remove the front-door assembly 2 Remove two screws callout

55Remove the front-door assembly 4

Remove the right-rear cover

Right-rear cover

58Remove the right-rear cover 2

Remove the rear cover

Rear cover

61Remove the right-door assembly 2

Right-door assembly

63Remove the right-door assembly 4 Removal and replacement

65Remove the right-door assembly 6

67Remove the right-door assembly 8 Removal and replacement

68Remove the right-door assembly 9

Cassette feed guide

Internal assemblies

72Remove the secondary transfer assembly 2

Secondary transfer assembly

Reinstall the secondary transfer assembly

Remove the separation pad Tray

Separation pad Tray

78Remove the separation pad 4 Removal and replacement

Enww

Remove the RD sensor assembly

Registration density RD sensor assembly

84Remove the RD sensor assembly 4

86Remove the RD sensor assembly 6 Removal and replacement

Carefully remove the assembly from the product

Registration assembly

89Remove the registration assembly 2

Remove the registration assembly

91Remove the registration assembly 4 Removal and replacement

93Remove the registration assembly 6

95Remove the registration assembly 8 Removal and replacement

Remove the residual-toner-feed motor

Residual-toner-feed motor

Remove the residual-toner duct and feed assembly

Residual-toner duct and feed assembly

99Remove the residual-toner duct and feed assembly 3

Enww

Remove the cartridge fan and environmental sensor

Cartridge fan and environmental sensor

Enww

Enww

Enww

Toner-collection sensor and scanner-thermistor assembly

Open the front-door assembly, and then remove one screw

Remove the delivery fan

Delivery fan

112Remove the delivery fan 2 Removal and replacement

Remove the delivery assembly

Delivery assembly

115Remove the delivery assembly 3 Removal and replacement

Remove two screws

118Remove the delivery assembly 6 Remove the assembly

121Reinstall the delivery assembly 2

Reinstall the delivery assembly

123Reinstall the delivery assembly 4 Removal and replacement

Remove the duplex-drive assembly

Duplex-drive assembly

Remove the power-supply fan

Power-supply fan

Remove the ICB

Interconnect board ICB

127Remove the ICB 2 Removal and replacement

Remove the DC controller PCA only

DC controller PCA only

Enww

Remove the low-voltage power supply

Low-voltage power supply Lvps

Enww

134Remove the low-voltage power supply 4

Enww

Remove the DC controller PCA and tray

DC controller PCA and tray

Remove two screws

Remove the high-voltage power supply lower

High-voltage power supply lower HVPS-D

Remove three screws

142Remove the high-voltage power supply lower 3

Release five tabs

Reinstall the high-voltage power supply lower

146Remove the high-voltage power supply lower 7

Remove the developing-disengagement motor

Developing-disengagement motor

Remove the exhaust fan and fan duct

Exhaust fan and fan duct

Enww

152Reinstall the exhaust fan and fan duct

Reinstall the exhaust fan and fan duct

Remove the pickup motor

Pickup motor

Remove the lifter-drive assembly

Lifter-drive assembly

Enww

Remove the lifter base assembly

Lifter base assembly

158Remove the lifter base assembly 2

Reinstall the lifter base assembly

160Reinstall the lifter base assembly 2

Remove the tray-pickup drive assembly

Tray-pickup drive assembly

163Remove the tray-pickup drive assembly 3

Remove the tray-pickup assembly

Tray-pickup assembly

Enww

168Remove the tray-pickup assembly 5 Removal and replacement

Enww

172Remove the tray-pickup assembly 9 Removal and replacement

173Remove the tray-pickup assembly 10

Laser/scanner assembly Y/M

176Remove the laser/scanner assembly Y/M 2

Remove the laser/scanner assembly Y/M

Enww

179Remove the laser/scanner assembly Y/M 5

Laser/scanner assembly C/Bk

181Remove the laser/scanner assembly C/Bk 2

Remove the laser/scanner assembly C/Bk

Enww

Reinstall the protective glass cleaner PGC actuators

184Remove the laser/scanner assembly C/Bk 5

187Reinstall the PGC actuators 3 Removal and replacement

189Reinstall the PGC actuators 5

Remove the high-voltage power supply upper

High-voltage power supply upper HVPS-T

191Remove the high-voltage power supply upper 2

Reinstall the high-voltage power supply upper

Remove the yellow, magenta, cyan, and black drum motors

Yellow, magenta, cyan, and black drum motors

Fuser motor

194Remove the fuser motor

Remove the fuser motor

Remove the ITB motor

ITB motor

Main-drive assembly

197Remove the main-drive assembly 2 Removal and replacement

Remove the main-drive assembly

198Remove the main-drive assembly 3 Remove 10 screws

Enww

203Reinstall the main-drive assembly 2

Reinstall the main-drive assembly

Enww

Enww

Enww

Fuser-drive assembly

Remove the fuser-drive assembly

212Remove the fuser-drive assembly 4

213Remove the fuser-drive assembly 5 Remove three screws

Reinstall the fuser-drive assembly

215Remove the fuser-drive assembly 7

Front door optional paper feeder

Enww

Rear cover optional paper feeder

220Remove the right-front cover optional paper feeder

Right-front cover optional paper feeder

Right door optional paper feeder

Enww

Remove the left cover optional paper feeder

Left cover optional paper feeder

Enww

Remove the right cover optional paper feeder

Right cover optional paper feeder

Remove the rear-right cover optional paper feeder

Rear-right cover optional paper feeder

Remove the pickup assembly optional paper feeder

Pickup assembly optional paper feeder

231Remove the pickup assembly optional paper feeder 3

Enww

Remove the lifter assembly optional paper feeder

Lifter assembly optional paper feeder

Remove the lifter-drive assembly optional paper feeder

Lifter-drive assembly optional paper feeder

Remove the pickup motor optional paper feeder assembly

Pickup motor assembly optional paper feeder

Remove the controller PCA optional paper feeder

Controller PCA optional paper feeder

Solve problems

Solve problems checklist

Solve problems checklist

Print a menu map

Menu map

Determine the problem source

Troubleshooting process

Pre-troubleshooting checklist

1Pre-troubleshooting checklist

Calibrate the product on

2Troubleshooting flowchart

Troubleshooting flowchart

Power on

Event log Information pages Image quality Interface

Power-on checks

Power subsystem

Power-on troubleshooting overview

Power-on timing approximate

Enww

Individual component diagnostics

Tools for troubleshooting

LED diagnostics

Understand lights on the formatter

Heartbeat LED

Engine diagnostics

Defeating interlocks

Engine-test button

Disable cartridge check

3Engine-test button

Paper-path test

Default state of bits

3Manual sensor diagnostic tests

Sensor or switch name Sensor or switch number

Manual sensor test special-mode test

TOP top of page sensor

C loop sensors

Fuser delivery sensor

Duplex re-pickup sensor

Output bin full sensor

Developer alienation

Fuser pressure-release sensor

Primary transfer-roller-disengagement sensor

Enww

16 Media sensor

Media sensor

Front-door switch

Right-door switch

Manual sensor test 2 special-mode test

5Manual sensor test 2 diagnostic tests

Test each switch individually Solve problems

Tray 1 paper present sensor

Tray 2 paper present sensor

Tray 2 paper surface 1 and 2 sensors

Tray 2 paper size switches

Tray 3 paper present sensor

Tray 3 paper size switches

Tray 3 feed sensor

Tray 3 paper surface 1 and 2 sensors

Tray 5 paper size switches

Tray 4 paper size switches

Tray 5 paper present sensor

Tray 5 feed sensor

Enww

Defeating

Enww

Enww

25Test the new ITB sensor

New ITB sensor

26Test the right door switch Solve problems

Tray 3, 4, and 5 right door switch

Paper-path sensors test

7Paper-path sensors diagnostic tests

Print/stop test

Sensor name Sensor number

Component test special-mode test

Component tests

8Component test details

Fuser Motor

Yellow Laser Scanner

Fuser Pressure Release Motor

Alienation Motor

Repeat

Duplex Refeed Clutch Solenoid

Block diagrams

Diagrams

28Optional paper feeder 1 x 500-sheet

29Optional paper feeder 3 x 500-sheet

9Formatter PCA

Plug/jack locations

DC controller connector locations

Location of connectors

10DC controller connectors

11Controller PCA connectors

32Controller PCA connectors

33External component locations

Locations of major components

34Major component locations 1

35Major component locations 2

36Major component locations 3

Ite Description

11 9

38PCA component locations

39Optional paper feeder 1 x 500-sheet component locations 1

40Optional paper feeder 1 x 500-sheet component locations 2

41Optional paper feeder 3 x 500-sheet component locations 1

42Optional paper feeder 3 x 500-sheet component locations 2

Timing chart

General timing chart

General circuit diagram 1

Circuit diagrams

Control

Paper feeder circuit diagram 1 X 500-sheet

Paper feeder circuit diagram 3 X 500-sheet

Open the HP Easy Printer Care software

HP Easy Printer Care

HP Easy Printer Care software sections

Section Options Support tab

Settings tab

HP Proactive Support

Overview and Support tabs

Color Access Control

Section Options Alert Settings link

Internal print-quality test pages

Print-quality-troubleshooting pages

Yellow Green

51Black print-quality troubleshooting

Diagnostics

Diagnostics

Create and use the cleaning

Cleaning

Configuration

Configuration

Memory Event log Security Paper trays and options

HP embedded Jetdirect

Security Settings information

54 Embedded protocol

Embedded protocol

12Important information on the configuration pages

Finding important information on the configuration pages

Color-band test

Repetitive defects ruler

Print-quality troubleshooting tools

Calibrate the product

Control panel menus

Control panel menus

Show Me How menu

Retrieve job menu

Enww

ALL Jobs no PIN Print

When Print or Print and Delete is

Hold jobs, Print and Delete is

Delete

Paper handling menu

Information menu

Manage supplies menu

Continue

Color Cartridges Stop

Print in Black

Transfer KIT Stop

Magenta Cartridge

User Defined LOW Yellow Cartridge

Cyan Cartridge

Black Cartridge Transfer KIT

Printing menu

Configure device menu

Default Custom Paper Unit of Measure

Default Paper Size

Size Dimension

Print PS Errors OFF

PCL sub-menu

Print Quality menu

X1 Shift

Mode Expanded

Y1 Shift

X2 Shift

Print Mode

Adjust Paper

Restore Optimize

NOW Delay

Cleaning

Auto Cleaning OFF

Auto Cleaning Letter

Edge Control OFF

Create

Select the Create Cleaning

Process

System setup menu

Disabled

PS Defer Media Enabled

USE Requested Tray Exclusively

First

Letterhead Mode OFF

USE Another Tray Enabled

Sleep Delay Minute

Alternative

Custom

Wake Time

Optimum SPEED/ENERGY Faster First

Usage Save Energy

Auto Continue OFF

JAM Recovery Auto

RAM Disk Auto

Language

13Embedded Jetdirect menu

Menu

Settings Subnet Mask

IPV4 Settings Config Method Bootp

Default

Default IP Auto IP

Settings

IPV6 Settings Enable

Dhcp Renew

Primary DNS

IPX/SPX Enable

Idle Timeout

Appletalk Enable

OFF DLC/LLC Enable

Reset

Disable

Reset Security YES

Diagnostics Embedded Tests

Data Path Test YES

Snmp Test YES

Select ALL YES

Tests

Ping Results

Print Results YES

Packets Sent

Packets

Link Speed Auto 10T Half 10T Full 100TX Half 100TX Full

Refresh YES

Diagnostics menu

Resets menu

Paper Path Test

Paper Path Sensors

Source ALL Trays

Tray

Product PINs

Service menu

Voltage power supply

Color Band Test Print Test

Control-panel message types

Interpret control-panel messages

Control-panel messages

XX values

13.XX.YY Fuser Wrap JAM

13.XX.YY Fuser Area JAM

13.XX.YY JAM Above TOP Output BIN

13.XX.YY JAM in Lower Right Door

Embedded I/O Buffer Overflow

Transfer Unit Error

Parallel I/O Buffer Overflow

Parallel Serial Buffer

Fuser Error

Xxxx Error

To continue turn off then on

See Fuser on

XX Error

XY Error

55.XX.YY DC Controller Error

See DC controller PCA and tray

Error

Description Recommended action Error

BO Cleaning Motor Error

59.A0 Error

59.C0 Error

Replace Toner Collection Unit

59.F0 Error

No System

Values

Permanent Storage Full

8X.YYYY EIO Error

Storage Error Settings

8X.YYYY Embedded Jetdirect Error

Changed

Black Cartridge LOW

Calibration Reset Pending

Black Cartridge LOW Less than Xxxx Pages

Black Cartridge Very LOW

Card Slot Device Failure

Cleaning Disk X% Complete

Card Slot File Operation Failed

Card Slot File System is Full

Close Lower Right Door

Cleaning Cyan Cartridge LOW

Close Right Door

Collection Unit Almost Full

Data Received

Cyan Cartridge Very LOW

DATE/TIME = YYYY/MMMM/DD Hhmm

EIO X Disk Initializing

EIO is Write Protected

HP Secure Drive Disabled

EIO not Initialized

Expected Drive Missing

Install Fuser

Install Color Cartridge

Install Supplies

Install Transfer Unit

Media insert required in tray

Magenta Cartridge LOW

Loading Program

Magenta Cartridge LOW Less than Xxxx Pages

Magenta Cartridge Very LOW

Moving Solenoid

NON HP Supply Installed

Moving Solenoid and Motor

Printing Stopped

RAM Disk File Operation Failed

RAM Disk Device Failure

RAM Disk File System is Full

RAM Disk is Write Protected

Remove Shipping Sheet

Replace Supplies Using black only

Replace Color Cartridge

Replace Fuser KIT

ROM Disk Device Failure

Replace Transfer KIT

ROM Disk File System is Full

ROM Disk File Operation Failed

ROM Disk is Write Protected

Sanitizing Disk X% Complete

Manage Supplies menu on

Supplies LOW

Printing Black only

Supplies Very LOW

Toner Collection Unit Very LOW

Toner Collection Unit LOW

Transfer KIT LOW

Transfer KIT LOW Less than Xxxx Pages

Tray X Empty Type Size

Tray X Type Size

Tray X Open

Tray X Overfilled

Unsupported Supply Installed

Unsupported Drive Installed

USB Accessory Error

USB Accessory not Functional

Waiting for Tray X to Lift

Wait for Printer to Reinitialize

Warming UP

Yellow Cartridge LOW

Yellow Cartridge Very LOW To continue press OK

Yellow Cartridge Very LOW

Print an event log

Event log messages

Show an event log

Clear the event log

Sample event log

Event log message Description Comments

Event log message table

Quick Calibrate NOW,

Configure DEVICE, and then

Then press theOK button

DC controller Nvrm is not

Reading the header number and size 99.00.08

Common causes of jams

Clear paper jams

Product is jammed

ITB

Jam code

15Common causes of jams by area

Jam locations

Type of jam Procedure

13.XX.YY JAM in Optional Trays

Clear jams in the right door

Enww

Enww

Clear jams in Tray

Clear jams in the output bin area

Enww

Clear jams in Tray 2 or optional Trays 3, 4, or

Clear jams in the lower right door Tray 3, 4, or

Jams in the output bin

Jam causes and solutions

Jams in the fuser and transfer area

19Causes and solutions for fuser delivery stationary jams

21Causes and solutions for pickup delay jams

20Causes and solutions for residual media jams

23Causes and solutions for duplexing reverse jams

22Causes and solutions for pickup stationary jams

24Causes and solutions for duplex repick jams

Right-door assembly on

25Causes and solutions for residual media jams

Jams in Tray 1, Tray 2 and internal paper path

26Causes and solutions for pickup delay jam 1 tray pickup

Jams in Tray 3, 4,

27Causes and solutions for pickup stationary jams

29Causes and solutions for residual media jams

Set the jam recovery feature

Change jam recovery

Product feeds multiple sheets

Solve paper-handling problems

Product feeds incorrect page size

Product pulls from incorrect tray

Paper does not feed from Tray 2, 3, 4, or

Paper does not feed automatically

Paper does not feed automatically

Paper does not feed from Tray 2, 3, 4, or

Envelopes jam or will not feed in the product

Transparencies or glossy paper will not feed

Transparencies or glossy paper will not feed

Envelopes jam or will not feed in the product

Product will not duplex or duplexes incorrectly

Output is curled or wrinkled

Output is curled or wrinkled

Automatic Configuration list

Under Installable Options, click Update Now

Properties or Printing Preferences

PRE-ROTATION Mode

30MP modes under the Adjust Paper Types sub menu

Use manual print modes

31MP modes under the Optimize submenu

Problem Sample Cause Solution

Solve image-quality problems

Image defects table

Transfer belt ITB on

Assembly Y/M on page 186 or

Power supply lower HVPS-D

Assembly. See Secondary transfer

Execute a Pressure roller clean

Clean the paper path

Clean the product

Clean the product

Problem Cause Solution

Solve performance problems

Solve direct-connect problems

Solve connectivity problems

Solve network problems

Solve connectivity problems

Service menu

Service mode functions

Refurbish Cycle Count

Refurbish page Count

Serial Number

Cold Reset Paper

Service ID

NEW Registration Roller

Media Sensor Value

Restore factory-set defaults

Product resets

Hard disk initialization optional

Nvram initialization

Product cold reset

Product updates

Parts and diagrams

Order parts, accessories, and supplies

Part numbers

Accessories

Print cartridges and toner collection unit

Memory

1Maintenance kits

Service maintenance kits

Customer self repair CSR parts

2110V and 220V unique components

Unique components

3Simplex and duplex unique components

4Common fasteners

Screws

How to use the parts lists and diagrams

1External covers, panels, and doors

External covers, panels, and doors

Description Part number Qty

5External covers, panels, and doors

2Right door assembly

Right door assembly

6Right door assembly

Front door assembly

7Front door assembly

Internal components 1

Internal components

8Internal components 1

Internal components 2

9Internal components 2

6Internal components 3

Internal components 3

10Internal components 3

Internal components 4

11Internal components 4

8Internal components 5

Internal components 5

12Internal components 5

Simplex Model Duplex Model

Internal components 6

13Internal components 6

10Internal components 7

Internal components 7

14Internal components 7

Cassettes

Cassettes

15 Cassette

Paper pickup assembly

16Paper pickup assembly

13Tray 1 paper pickup assembly

Tray 1 paper pickup assembly

17Tray 1 paper pickup assembly

Simplex Model Duplex Model

18Registration assembly

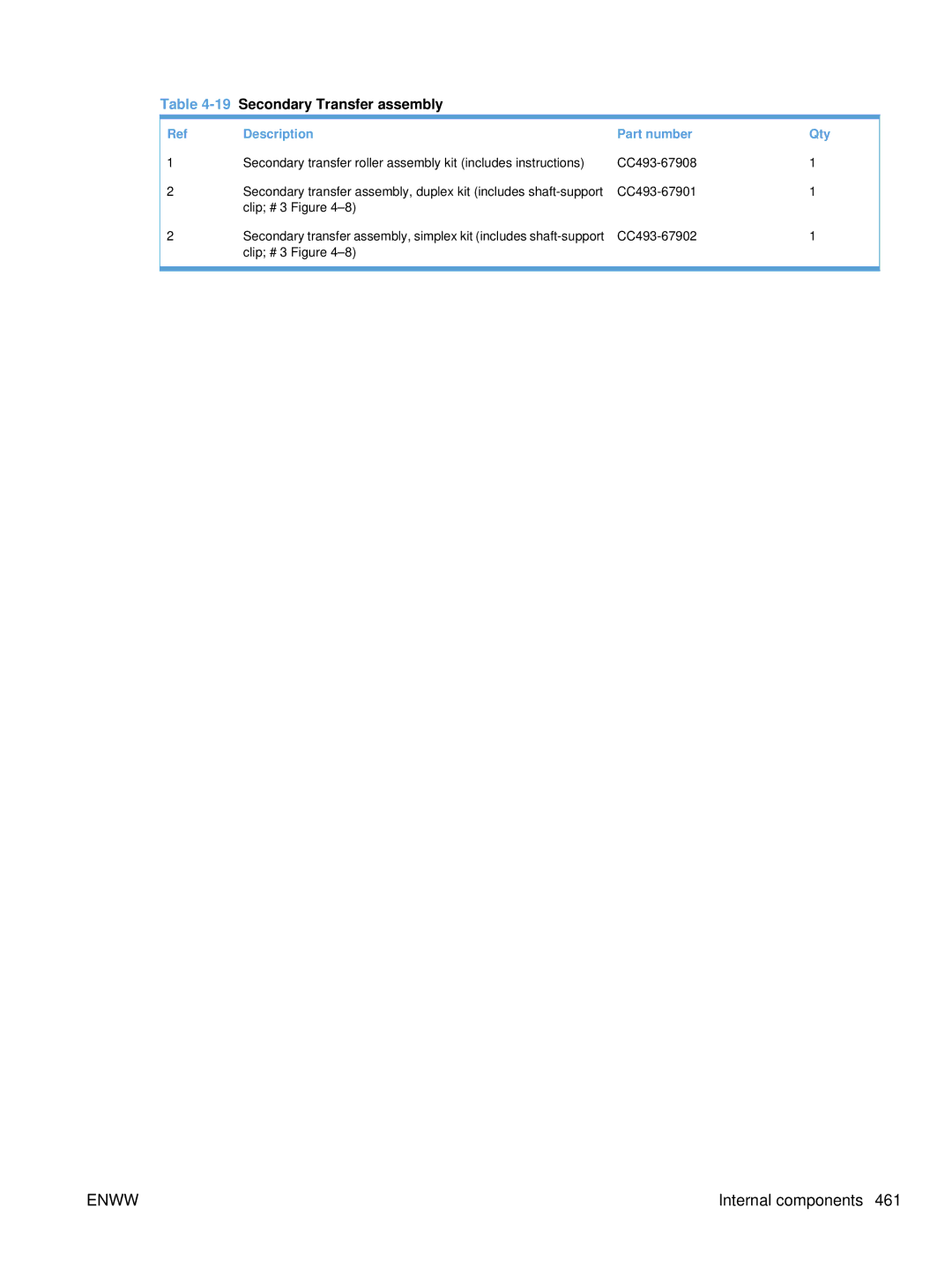

15Secondary transfer assembly

19Secondary Transfer assembly

16Delivery assembly

20Delivery assembly

Fuser assembly

Fuser assembly

21Fuser assembly

18 PCAs

PCAs

22 PCAs

Paper feeders

Assessories

Paper feeders

23Paper feeders

1x500 3x500

Paper feeder external covers, panels, and doors

24Paper feeder external covers, panels, and doors

500 paper feeder main body

500 paper feeder main body

251 X 500 paper feeder main body

223 X 500 paper feeder main body

263 X 500 paper feeder main body

27Alphabetical parts list

Alphabetical parts list

Alphabetical parts list

Delivery assembly

Fuser drive assembly, simplex RM1-6702-000CN

Paper pickup assembly

Tray 1 paper pickup assembly

Shutter arm assembly RM1-5585-000CN

Upper main cable assembly RM1-5800-000CN

28Numerical parts list

Numerical parts list

RC2-4218-000CN Tray, waste toner catch

Enww

RK2-2604-000CN Flat flexible cable DCC to Hvps lower

RM1-5520-000CN Cover, inner

RM1-5781-000CN High voltage power supply, upper

Enww

WC2-5637-000CN Switch, push

Enww

Service and support

Hewlett-Packard limited warranty statement

Page

HP Color LaserJet Fuser Kit Limited Warranty Statement

Transfer

End User License Agreement

Enww

Customer self-repair warranty service

Customer support

Product specifications

Performance specifications

Physical specifications

Electrical specifications

Table B-1Product dimensions

Environmental specifications

Acoustic specifications

Table B-3Power requirements

Table B-4Power consumption average, in watts1246

Table B-6Media registration and image placement accuracy

Skew specifications

Regulatory information

FCC regulations

Environmental product stewardship program

Paper

Return and recycling instructions

United States and Puerto Rico

Non-U.S. returns

Chemical substances

Material restrictions

HP Color LaserJet Enterprise CP4020-CP4520 Series

Material Safety Data Sheet Msds For more information

Declaration of Conformity

Laser safety

Safety statements

Vcci statement Japan Power cord instructions

Power cord statement Japan

Varoitus

GS statement Germany

Cabinet/stand

Symbols/Numerics

Dhcp

See also jams

Nvram

See also counts

Enww

Recycling

Enww

See also cassette

Enww

Page

CC489-90936* *CC489-90936