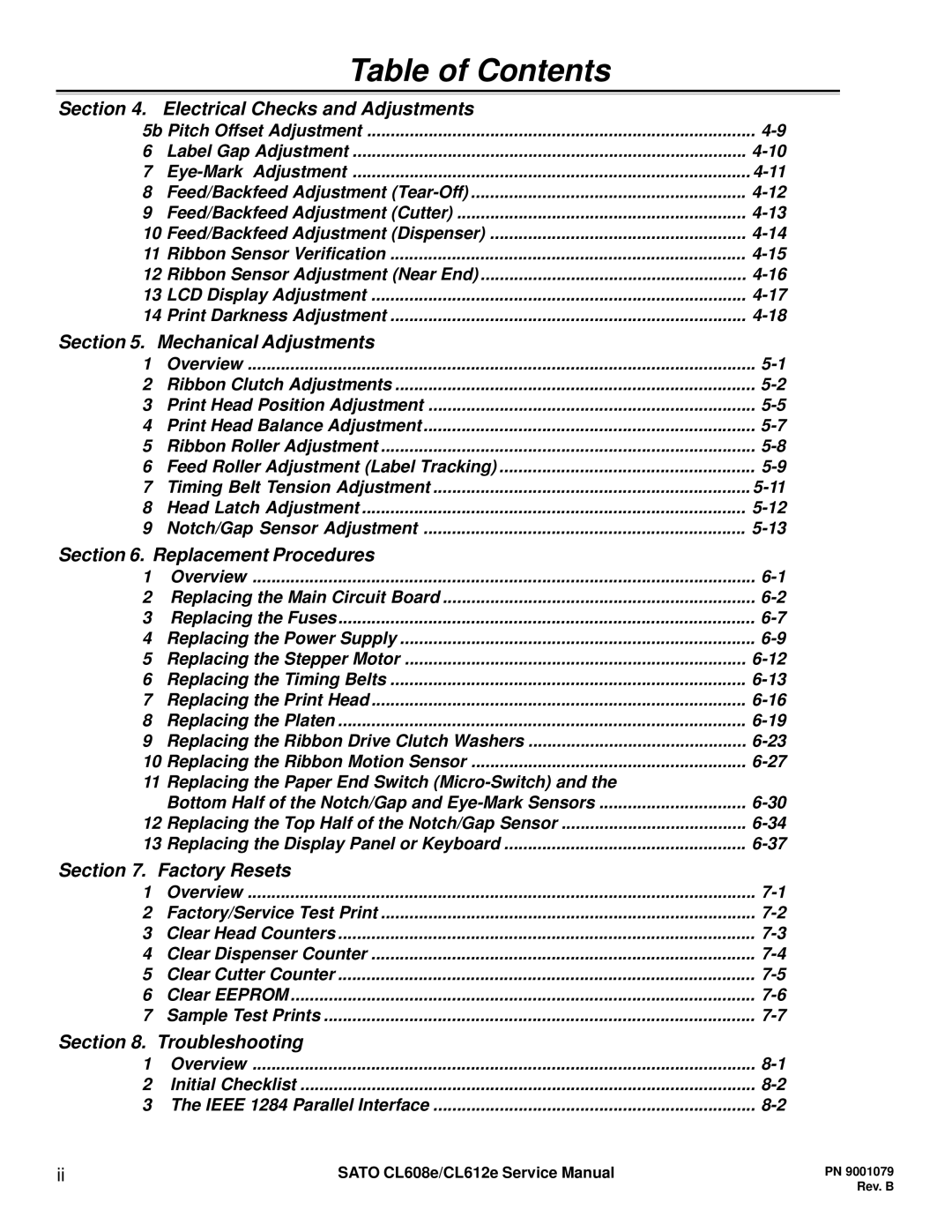

Table of Contents

Section 4. Electrical Checks and Adjustments

5b Pitch Offset Adjustment | ||

6 | Label Gap Adjustment | |

7 | ||

8 | Feed/Backfeed Adjustment | |

9 | Feed/Backfeed Adjustment (Cutter) | |

10 | Feed/Backfeed Adjustment (Dispenser) | |

11 | Ribbon Sensor Verification | |

12 | Ribbon Sensor Adjustment (Near End) | |

13 | LCD Display Adjustment | |

14 | Print Darkness Adjustment | |

Section 5. Mechanical Adjustments

1 | Overview | |

2 | Ribbon Clutch Adjustments | |

3 | Print Head Position Adjustment | |

4 | Print Head Balance Adjustment | |

5 | Ribbon Roller Adjustment | |

6 | Feed Roller Adjustment (Label Tracking) | |

7 | Timing Belt Tension Adjustment | |

8 | Head Latch Adjustment | |

9 | Notch/Gap Sensor Adjustment |

Section 6. Replacement Procedures

1 | Overview | |

2 | Replacing the Main Circuit Board | |

3 | Replacing the Fuses | |

4 | Replacing the Power Supply | |

5 | Replacing the Stepper Motor | |

6 | Replacing the Timing Belts | |

7 | Replacing the Print Head | |

8 | Replacing the Platen | |

9 | Replacing the Ribbon Drive Clutch Washers | |

10 | Replacing the Ribbon Motion Sensor | |

11 | Replacing the Paper End Switch |

|

| Bottom Half of the Notch/Gap and | |

12 | Replacing the Top Half of the Notch/Gap Sensor | |

13 | Replacing the Display Panel or Keyboard |

Section 7. Factory Resets

1 | Overview | |

2 | Factory/Service Test Print | |

3 | Clear Head Counters | |

4 | Clear Dispenser Counter | |

5 | Clear Cutter Counter | |

6 | Clear EEPROM | |

7 | Sample Test Prints |

Section 8. Troubleshooting

1 | Overview | |

2 | Initial Checklist | |

3 | The IEEE 1284 Parallel Interface |

ii | SATO CL608e/CL612e Service Manual |