Section 5. Mechanical Adjustments

5.4 Print Head Balance Adjustment

Required Equipment: | • | #2 Pozidrv Screwdriver |

| • | 10mm wrench |

To optimize print quality, perform the following steps to adjust the Print Head Balance using head pattern as a guide. Proper adjustment is necessary to avoid ribbon wrinkle.

STEP PROCEDURE

1.Connect the power cable to the printer and AC outlet. Turn the printer ON.

2.Raise the access door and load the ribbon and label stock. NOTE: It is vital that a known good platen be in the unit.

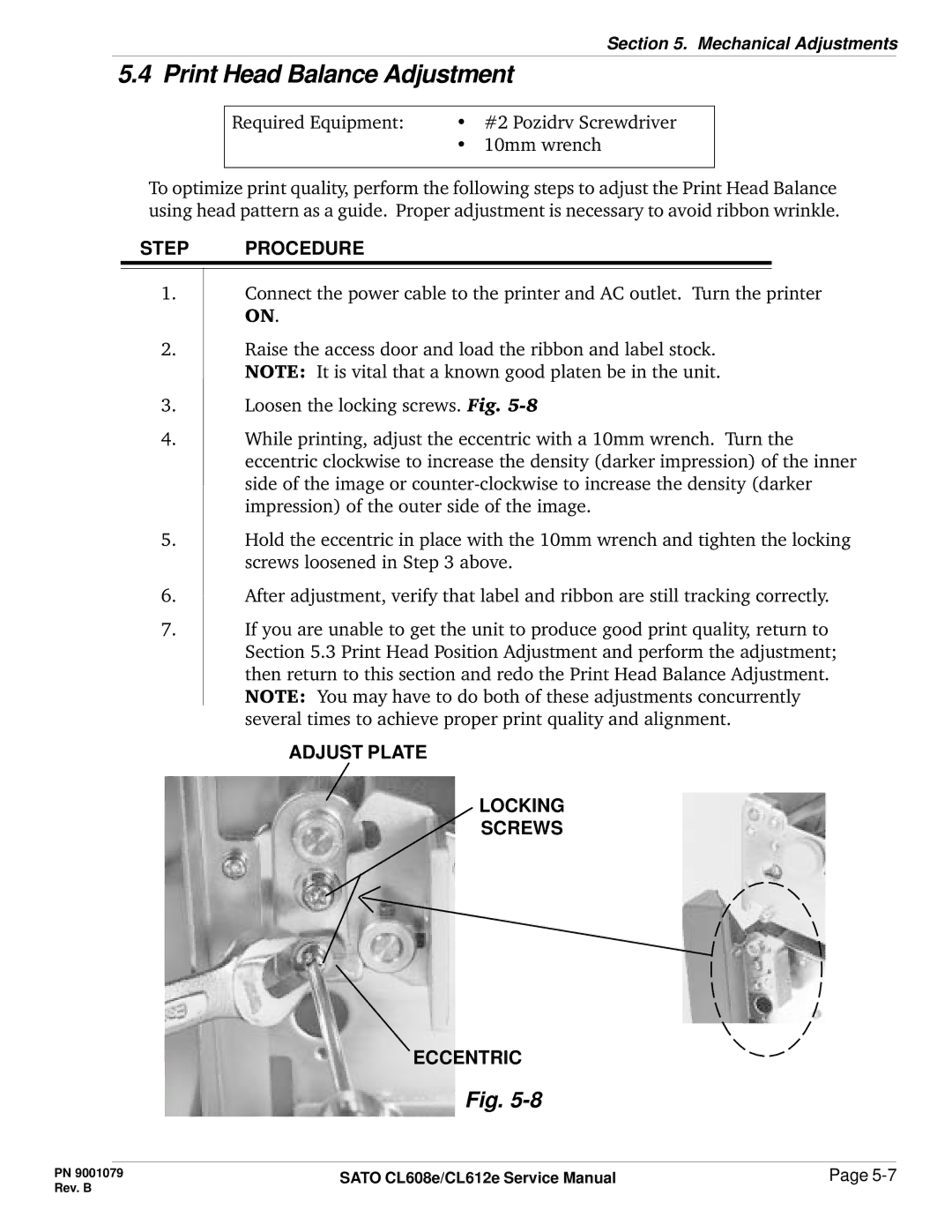

3.Loosen the locking screws. Fig.

4.While printing, adjust the eccentric with a 10mm wrench. Turn the eccentric clockwise to increase the density (darker impression) of the inner side of the image or

5.Hold the eccentric in place with the 10mm wrench and tighten the locking screws loosened in Step 3 above.

6.After adjustment, verify that label and ribbon are still tracking correctly.

7.If you are unable to get the unit to produce good print quality, return to Section 5.3 Print Head Position Adjustment and perform the adjustment; then return to this section and redo the Print Head Balance Adjustment. NOTE: You may have to do both of these adjustments concurrently several times to achieve proper print quality and alignment.

ADJUST PLATE

LOCKING

SCREWS

ECCENTRIC

Fig.

PN 9001079 | SATO CL608e/CL612e Service Manual | Page |

Rev. B |

|

|