DCP301 Digital Program Controller User’s Manual

EN1I-6197 Issue 7 02/04

Warranty

Safety Precautions

Page

Handling Precautions

Name Model No ’ty Remarks

Unpacking

Troubleshooting

Wiring

Parameter Setup

Program Setup

Contents

Operation

Functions

Program Setup

Parameter Setup

Troubleshooting

Index

Specifications

Calibration

Conventions Used in This Manual

Enhanced compatibility with PLC

Features

High accuracy achieved by multi-range input

Wide range of control output types

Basic Function Blocks

RUN/HOLD Reset ADV Fast AUTO/MANUAL

Parameters

Data Structure

System configuration by CPL communications

System Configuration

Model selection guide

Model Numbers

Names & Functions of Parts

Structure

Display

Console

Basic display state

MAN

Category Function Key operation

Keys

Assignment item

Setup

Program setup

To start program copy

Loader jack

Functions using two or more keys

Thermocouple

Resistance temperature detector RTD

Input Type and Range No

Inputs

Input Format Range No Code Range programmable

Dc current, dc voltage

Mounting

External Dimensions

Panel Cutout Dimensions

Mounting locations

Mounting

Type Confirmation on Display Operation Hard

Noise generating sources and countermeasures

Dust-proof cover

Mounting method

Handling Precautions

Wiring Precautions

Wiring

Handling Precautions

Hitachi Cable Co

Wiring

Compensating Lead

Terminal Connections

Layout of Terminals and Recommended Lead Draw-out Direction

Ground

Connecting the Ground and Power Supply

Power supply

Add-on terminal layout

Wiring of Standard and Add-on Terminal Base

Standard terminal layout

Connecting input

Connecting Inputs analog inputs

Position-proportional output 2G

Connecting control outputs outputs 1

Relay output 0D

Current output 5G

Heat/cool output 5K

Voltage output 6D

Heat/cool output 3D

2G, 3D, 5K auxiliary outputs

Connecting auxiliary outputs outputs 2

0D, 5G, 6D auxiliary outputs

Connecting Event Output relay output

Connecting Time Event Output open-collector

Connecting External Switch RSW Input

Wiring

RS-485 interface

Connecting for Communications

Wire system RS-485 mutual connection

RDA RDB

Control output 2G

Isolating Inputs and Outputs

Control outputs 0D, 5G, 6D, 3D, 5K

Functions

Data

Data types

Patterns

Program Patterns

PV type events

Events 1 to

OFF H

Time events

Controller status events

Onoff

Time events 1 to

Segment No. events

PID set selection

Soak guarantee soak

Cycle

PV start

Pattern link

Constant-value operation

Mode types

Modes

Program operation

RUN

During constant-value operation

Mode transition

During program operation

Program end

Mode transition operations

Manual

Mode transition limitations

Programmer

Controller and Programmer

Controller

Input processing is carried out in the order shown below

Input Processing Functions

5G output

Output Processing Functions

Control output

0D, 6D output

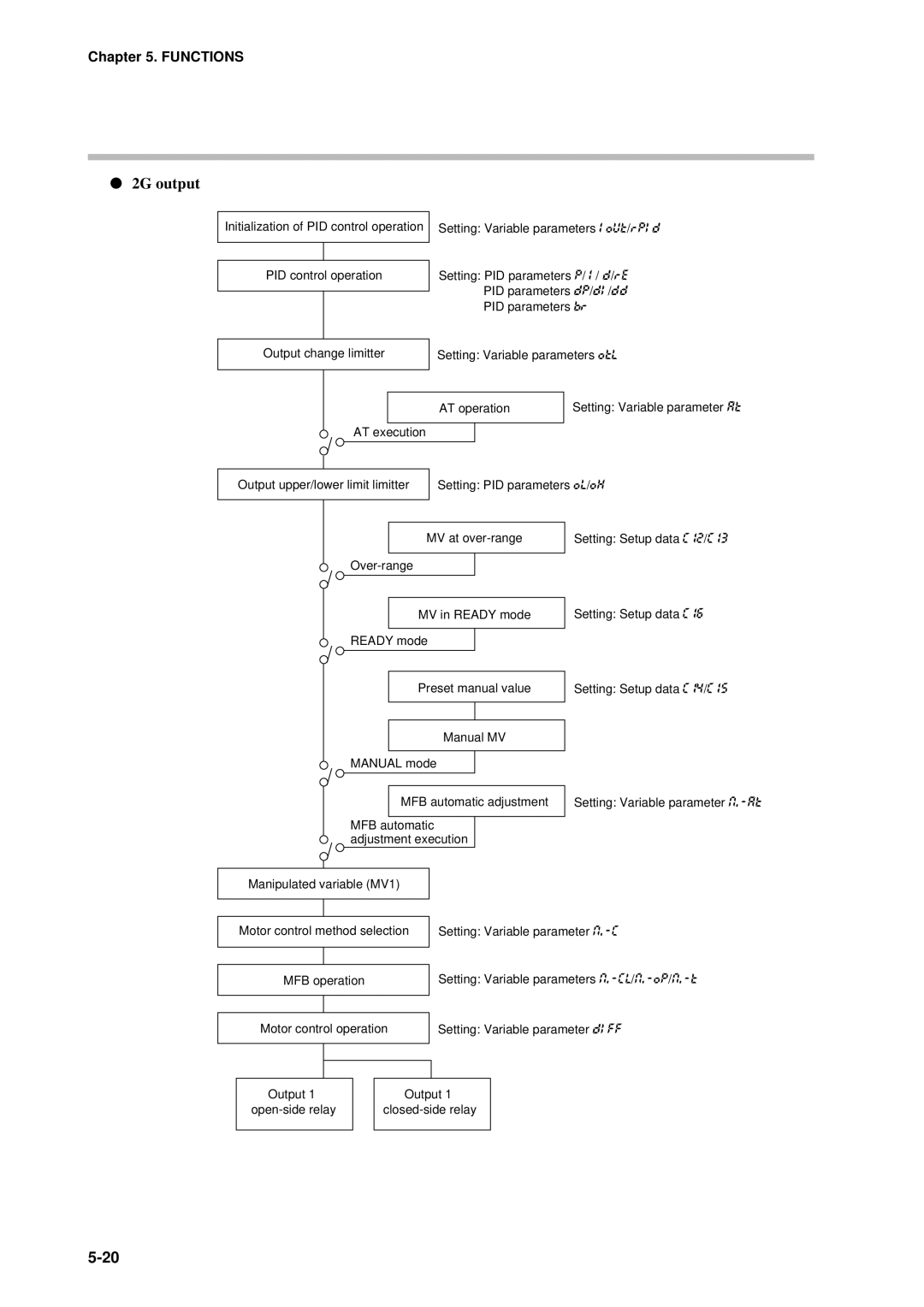

2G output

Dv-L/HY-L Dv-H/HY-H

3D, 5K outputs

Auxiliary output

SP output

Auxiliary output

Startup flow

Turning the Power on

Switching the Basic Display

Output Model No Display

Display in program operation mode

Disp functions

Display

CYC

Display in constant-value operation mode

Motor valve opening % Output state of events 1 to

Program Selection

How to select the program No

External Function Detection Method Switch No

External Switch RSW Operations

External switch RSW inputs

External switch input types

Program selection

External Weighting State Switch No

Timing of RSW8 to 12, RUN and PV start

Read timing

Timing of RSW1 to

Controller functions

Manual Operation and Auto-tuning

Auto-tuning AT

Manual operation

Pvsp

Name Upper Remarks Display

Parameter Setup

Selecting the setting group in the parameter setup

D E is

Moving individual items in the parameter setup

9 C 0

Base Setting Group

How to Use Para

How to register functions to keys

How to register assignment items

Order Item to Call by

Item Code Setting Auxiliary Value Remarks Display

Example

Operations by Para

Basic Display Para key State Max items

Variable parameter settings P a R a

Parameter Setup List

S T

Parameter Setup

T C program protect

Description of variable parameter settings

C key lock

I D PID operation initialization

L MV change limit

U t PID operation initial MV

I D 2 degrees of freedom

Smart-tuning method selection

F F

Cool

State Heat-side Output Cool-side Output

Cmotor control method selection

Tmotor valve opening adjustment fully open/closed time

T motor valve opening automatic adjustment

Manual

Event configuration data settings E

Parameter Setup

Parameter Setup

Parameter Setup

1 event 1 standby 2 event 2 standby 3 event 3 standby

Description of event configuration data

PID Set

PID parameter settings P I d

Parameter Setup

Parameter Setup

Parameter Setup

Setup data settings S E t

Parameters C P 1 to C P

NOP

Ready

To input

ROM ID

SP1 lower limit 0 SP1 upper limit

Description of setup data settings

7 input 1 square root extraction dropout

4 voltage time-proportional output system

5 time display

6 PV display

2 cold junction compensation

8 voltage output 1 adjustment Voltage output 2 adjustment

Formulas 3 and 4 formulas must be satisfied

0 Special functions

1 Input 1 Zener barrier adjustment

3 CPL communications port selection

Table data settings T B L

To t -A . b To t -b . b

Description of table data settings

D E

Constant-value operation data settings C N S t

Selecting the program No. to set up

Program Setup

How to enter program setup

Basic Display State Func + Prog keys

Description of mode transition states see

Shaded items Cannot be moved

Segment No Program No.1 setting 12 to

Programming map

Display details

Setting up pattern items

Display PV type event

Setting up events 1 to 3 items

When event type is PV type event

Display time event

When event type is time event

When event type is controller status event

Time event No Setting value

Setting up time events 1 to

PI D

Setting up PID set No. items

Setting up G.Soak time-out items

Setting up G.Soak guarantee soak items

Setting up cycle items

Setting up PV start items

Deleting programs

Setting up pattern link items

Display deleting segment

Inserting and deleting segments

Display inserting segment

Copying Programs

P Y

E S

General Reset

Intermittent self-diagnostics during operation

Self-diagnostics and Alarm Code Display

Self-diagnostics at power on

Self-diagnostics at each sampling cycle

Alarm categories

Self-diagnostics only when certain functions are operating

Alarm code display

Cause Remedy

Trouble during Key Entry

Controller is in the Ready mode Press

Troubleshooting

Items cannot be changed by pressing in program setup state

RUN. HOLD, FAST, END

Motor Adjustment is Impossible

C L

Normal wiring for direct motor rotation

Normal wiring for reverse motor rotation

Alarm display caused by wrong wiring and causes

Items to prepare

Replacing the Battery

BAT LED blinking

Replacement procedure Handling Precautions

Remove the battery connector from the RAM board

Gray holder

10-1

Specifications

Specifications

Specification

RSW

10-2

Auto

10-3

10-4

10-5

10-6

10-7

Accessories/option list

10-8

10-9

Soft dust-proof cover set sold separately

Hard dust-proof cover set sold separately

Terminal cover set sold separately

11-1

Precautions before calibration

Equipment needed

Calibration Items for Each Model

Model number DCP30 * * * * ES

11-2

Calibration

11-3

AdJS

11-4

Calibration Flowchart 1/2

11-5

Calibration Flowchart 2/2

SEG Display

Enter calibration mode

11-6

Prog Display

Upper Display

Function test

Key test

11-7

Terminal

Display test

Digital input test

11-8

11-9

Digital output test for control output

Digital output test for event

11-10

PV calibration

Key

Range Table of CH1 TC Group Type Code Range No. Gain No

11-11

11-12

Cold junction sensor calibration

Current output calibration

Press ENT key

11-13

11. Current Outputs

11-14

Programming Map

Safety Requirements

Index-1

Index

Index-2

Control output SP output

Index-3

Time event output open-collector connection

03-06 5th Edition

99-04 EN1I-6197 1st Edition 00-06 2nd Edition

00-08 3rd Edition

01-06 4th Edition

Honeywell Service Centers

Argentina

No. CP-UM-5093E