4220 Flow Meter

Section 2 Programming

current range is selected). The flow meter will then request that you repeat the process of defining the data type and setting the minimum and maximum values for any of the other analog ports you activated previously in Setup.

2.4.5Step 3 - Parameter to This step lets you enter the measured level in the flow stream. It

Adjust | also lets you calibrate the pH (acidity or alkalinity), D.O. (dis- | |

| solved oxygen) parameter sensors, and the YSI 600 Multiple | |

| Parameter Sonde. Note that there is no calibration step for the | |

| temperature sensor because it doesn’t need calibration. When | |

| you select step 3 the following will appear: | |

|

|

|

| PARAMETER TO ADJUST |

|

| • NONE • • (LEVEL) • • (pH) • • (D. O.) • • (YSI 600) • |

|

| LEVEL will not show up if you are using the flow meter only for | |

| parameter sensing. Likewise, pH and/or D. O. and YSI 600 will | |

| not show up on the display if you have locked them out by pro- | |

| gramming selections you made in step 1. | |

| Remember that selection of either pH or D. O. in step 1 will keep | |

| the other from appearing on the display in this or subsequent | |

| programming steps. If the parameter you want does not appear | |

| in this menu, exit the program and return to Setup. Check to see | |

| that you have not accidentally locked your choice out with selec- | |

| tions you made in the early section of the program. If you select | |

| NONE, the flow meter will advance to the next step. If you select | |

| LEVEL, the following will appear: | |

|

| |

| ENTER CURRENT LEVEL |

|

| X.XXX FEET (or meters) |

|

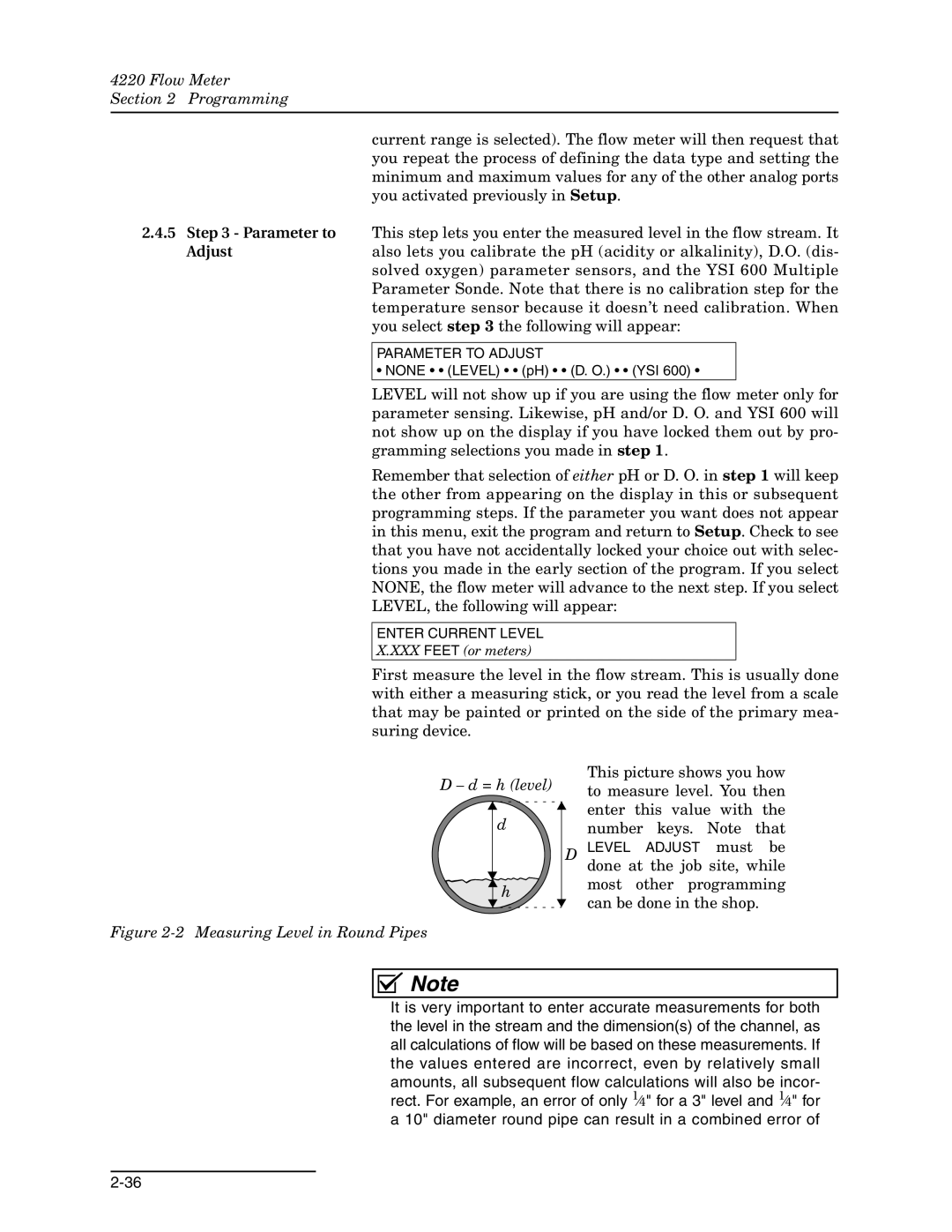

| First measure the level in the flow stream. This is usually done | |

| with either a measuring stick, or you read the level from a scale | |

| that may be painted or printed on the side of the primary mea- | |

| suring device. | |

D – d = h (level)

d

![]() h

h

This picture shows you how to measure level. You then enter this value with the number keys. Note that

D LEVEL ADJUST must be done at the job site, while most other programming ![]() can be done in the shop.

can be done in the shop.

Figure 2-2 Measuring Level in Round Pipes

![]()

![]()

![]()

![]()

![]() Note

Note

It is very important to enter accurate measurements for both the level in the stream and the dimension(s) of the channel, as all calculations of flow will be based on these measurements. If the values entered are incorrect, even by relatively small amounts, all subsequent flow calculations will also be incor- rect. For example, an error of only 1⁄4" for a 3" level and 1⁄4" for a 10" diameter round pipe can result in a combined error of