1020, 1218 specifications

The Alto-Shaam 1218 and 1020 are two innovative cooking solutions designed for modern culinary environments. Renowned for their advanced features and technologies, these units are ideal for a variety of food service operations including restaurants, catering businesses, and institutional kitchens.One of the standout characteristics of both models is the use of Halo Heat® technology. This unique heating method eliminates the need for water pans, resulting in a consistent, low-temperature cooking environment that retains moisture and enhances flavor while simplifying the cooking process. Halo Heat technology ensures that food is heated evenly, reducing the risk of overcooking or drying out, while also minimizing energy consumption compared to traditional cooking methods.

The Alto-Shaam 1218 has a larger capacity, accommodating up to 18 full-size food pans, making it suitable for high-volume cooking. In contrast, the 1020 model offers slightly less capacity but is designed for flexibility, perfect for venues with space constraints. Both models feature digital controls that provide precise temperature management, enabling chefs to set and monitor cooking times and temperatures easily.

Another key feature of these units is their versatility. They can be used for a wide range of cooking methods, including holding, slow-cooking, and even baking, allowing food service operators to maximize their kitchen efficiency. The cabinets are designed to accept optional roll-in racks, which streamline food preparation and storage processes.

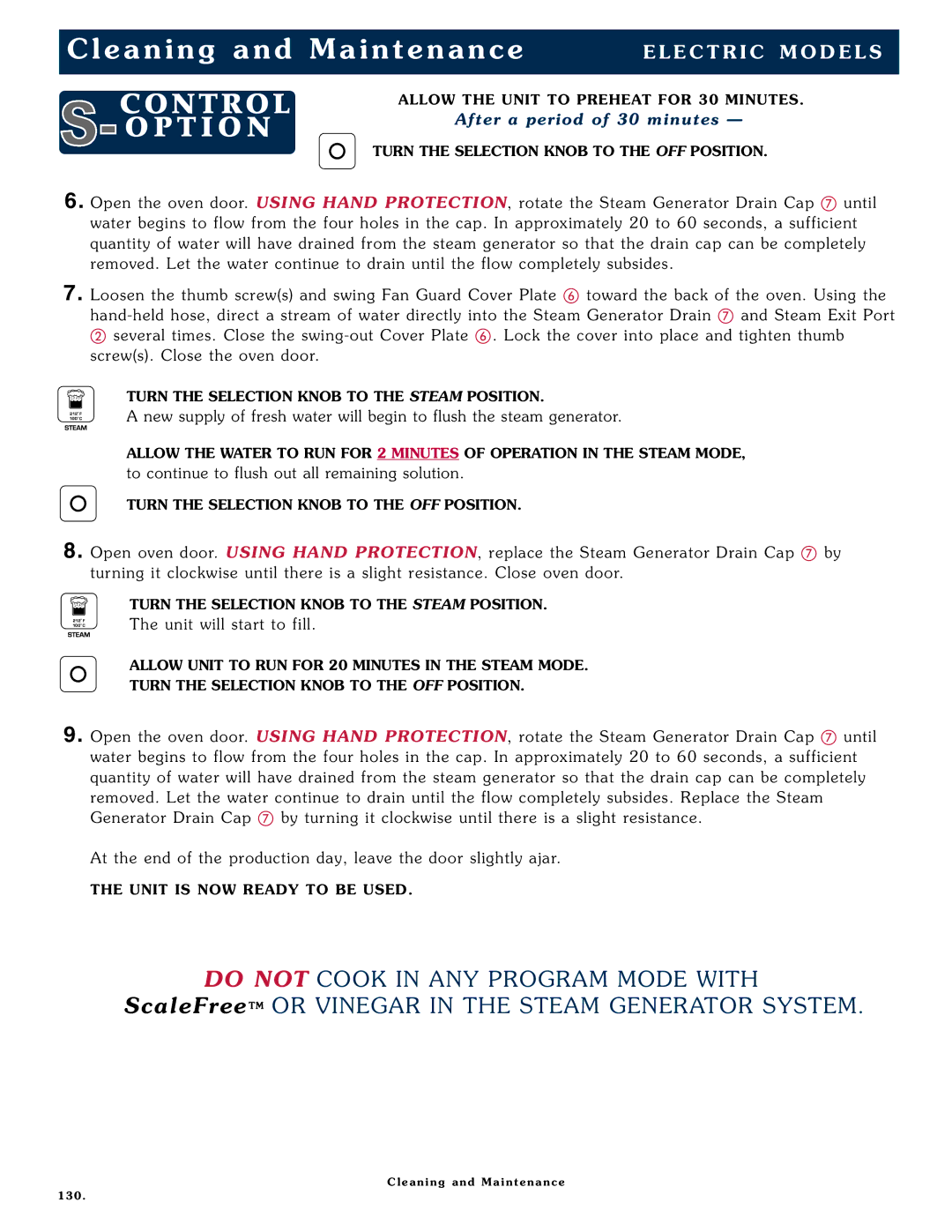

Alto-Shaam also emphasizes ease of cleaning and maintenance in the design of the 1218 and 1020 models. Smooth stainless-steel surfaces and removable components make it simple to keep the units hygienic, which is crucial in professional kitchen environments.

Moreover, both models are energy-efficient, contributing to lower operational costs and a reduced environmental footprint. Their durable construction promises long-lasting performance, ensuring a solid return on investment for food service operations.

Overall, the Alto-Shaam 1218 and 1020 embody a commitment to quality, efficiency, and innovation in the culinary industry. With their advanced technologies and user-friendly features, they present a reliable choice for chefs looking to elevate their food preparation and holding capabilities.