Sizes

FEATURES/BENEFITS

579F180-216

581A155,180

Table of Contents

FEATURES/BENEFITS

FEATURES/BENEFITS

580F036-150 Standard and Medium Efficiency 3 to 121/2 Tons

Model Number Nomenclature

581B036-150 High Efficiency 3 to 121/2 Tons

580F E V 060 120 N KB

580F180-300

Model Number Nomenclature 579F180-300

579F E V 180 230 - C B

580F E V 180 275 - C B

581A210-300 18 to 25 Tons

Model Number Nomenclature 581A155, 180, 181 13 to 15 Tons

581A E 180 230 - C B

A 2 5 0 - a

ARI* Capacity Ratings 580F036-151

Rise F Airflow CFM

ARI* Capacity Ratings

Capacity Airflow CFM

Unit

ARI* Capacity Ratings 581B036-150

Unit Input Capacity Output Capacity Temperature

Heating Capacities and Efficiencies 581B036-150

Unit Nominal Cooling Total SEER† Sound Rating Iplv

Unit Input Capacity Output Capacity Temperatur

Heating Capacities and Efficiencies 581B036-150cont

Heating

ARI* Capacity Ratings 579F180-300

LOW Outdoor Temperature Operating Limits F

Heating Capacities and Efficiencies 579F180-300

AIR Quantity Limits

Heating Capacities and Efficiencies 580F180-300

ARI* Capacity Ratings 580F180-300

AIR Quantity Limits Cooling

ARI* Capacity Ratings 581A155,180

LOW Outdoor AIR Temperature Cooling Operation Limits

Heating Capacities and Efficiencies 581A155-180

Heating Capacities and Efficiencies 581A210-300

ARI* Capacity Ratings 581A210-300

Option ACCESSORY†

Options and Accessories 581B036-150 and 580F036-151

579F180-300, 580F180-300, and 581A155-181

Options and Accessories

581A210-300

Options and Accessories

151

Physical Data 580F036-073

Unit Size 580F

Furnace Section

Physical Data 580F090,120,150 Units

LOSS-OF-CHARGE LOW-PRESSURE

Physical Data 580F091,103,121,151 Units

580F036-151

Ashrae 90.1 Compliant Units

Ashrae 90.1 Compliant Units

Base Unit Dimensions 580F036-072

Base Unit Dimensions 580F073

Base Unit Dimensions 580F090,120,150

Base Unit Dimensions 580F091,103,121,151

Unit Size Accessory CRRFCURB001A01

Accessory Dimensions 580F

ALT Accessory Drain GAS Power Control PKG. Accy Hole

Roof Curb

Roof Curb Details

Accessory Dimensions 580F

II Select Unit Based on Required Cooling Capacity

Selection Procedure with 580F060 example

Determine NET Cooling Capacity

Cooling Capacities

Performance Data

SHC

Entering AIR DRY-BULB Temp F

Cooling Capacities

Performance Data

Factor

Bypass Entering AIR DRY-BULB Temp F

580F151 121/ Tons Temp F

FAN Performance Vertical Discharge Units

580F048 4 Tons Standard Motor Direct Drive

FAN Performance Vertical Discharge Units

580F048 4 Tons Alternate Motor Belt Drive

580F048 4 Tons HIGH-STATIC Motor Belt Drive

580F060 5 Tons Standard Motor Direct Drive

580F060 5 Tons SINGLE-PHASE, Alternate Motor Belt Drive

580F060 5 Tons HIGH-STATIC Motor Belt Drive

580F060 5 Tons THREE-PHASE, Alternate Motor Belt Drive

580F072,073 6 Tons HIGH-STATIC Motor Belt Drive

580F072,073 6 Tons Standard Motor Belt Drive

505

580F090,091 71/2 Tons Standard Motor Belt Drive

531

584

580F090,091 71/2 Tons Alternate Motor Belt Drive

580F090,091 71/2 Tons HIGH-STATIC Motor Belt Drive

580F103 81/2 Tons Standard Motor Belt DRIVE*

580F103 81/2 Tons Standard Motor Belt Drive

580F103 81/2 Tons HIGH-STATIC Motor Belt DRIVE*

580F103 81/2 Tons HIGH-STATIC Motor Belt Drive

978

962

942

958

580F120 10 Tons Alternate Motor Belt Drive

746 713 811 883 870 1062 926

726 656 793 822 853 997 910

766 773 829 947 887 1131 942

786 836 847 1016 905 1204 958

580F121 10 Tons Standard Motor Belt Drive

949

580F121 10 Tons Alternate Motor Belt Drive

580F121 10 Tons Alternate Motor Belt DRIVE* Airflow

828

961 775

1030 787

1103 798

789

580F150,151 121/ Tons Standard Motor Belt Drive

848

804

580F150,151 121/ Tons Alternate Motor Belt Drive

FAN Performance Horizontal Discharge Units

1600 1189 1191 1700 1800 1900 2000 Bhp

FAN Performance Horizontal Discharge Units

Airflow Low Speed Medium Speed High Speed 208V 230, 460, 575

Bhp Brake Horsepower Input to Fan

Performance Data FAN Performance Horizontal Discharge Units

681

484

509

561

708

901

766

894

1293

1119

1388

1488

3100 637 1046

1912

1783

2047

2189

580F120,121 10 Tons Standard Motor Belt Drive

580F120,121 10 Tons Alternate Motor Belt Drive

580F120,121 10 Tons HIGH-STATIC Motor Belt Drive

990

835

580F150,151 121/ Tons Alternate Motor Belt Drive Airflow

Sound Weighted Octave Bands Unit 580F Rating

Outdoor Sound Power Total Unit

General Notes for FAN Performance Data Tables

Component CFM

FAN RPM AT Motor Pulley SETTINGS* 580F090-151

FAN RPM AT Motor Pulley SETTINGS* 580F036-073

Altitude COMPENSATION* 580F036-073 Standard Units

Altitude COMPENSATION* 580F036-073

580F036

Optional Power Exhaust

EVAPORATOR-FAN Motor Efficiency

Unit 580F EVAPORATOR-FAN Maximum Acceptable

EVAPORATOR-FAN Motor Performance

Continuous BHP Operating Watts AMP Draw

Power Exhaust Options

Electrical Data

Power Exhaust Electrical Data

71/2 Ton

Electrical Data

Unit Size Nominal IFM Voltage Range

150

580F090, 460-3-60 Shown

Typical Wiring Schematics 580F036-151

EconoMi$er IV Wiring 580F036-151 Units

Typical Wiring Schematics 580F036-151

EconoMi$er2 Wiring 580F036-151 Units

Convenience Outlet Optional Sizes 580F036-151

Typical Wiring Schematics 580F

Non-Fused Disconnect Optional Sizes 580F036-151

Vertical Discharge Ducting

Typical Piping and Wiring 580F036-151

Horizontal Discharge Ducting

Unit Size 581B

Physical Data 581B036-072

Nominal Capacity

581B036-150

Physical Data 581B090-150

Med

150

Base Unit Dimensions 581B036-072

Corner Weight

Base Unit Dimensions 581B090-150

Accessory Dimensions 581B036-072

Accessory Dimensions 581B090-150

Selection Procedure With 581B048 Example

150

Cooling CAPACITIES, Standard Units

Cooling CAPACITIES, Standard Units

581B120 10 Tons

581B036 3 Tons HOT GAS Reheat Mode

581B036 3 Tons Subcooling Mode

SHC

581B048 4 Tons HOT GAS Reheat Mode

581B048 4 Tons Subcooling Mode

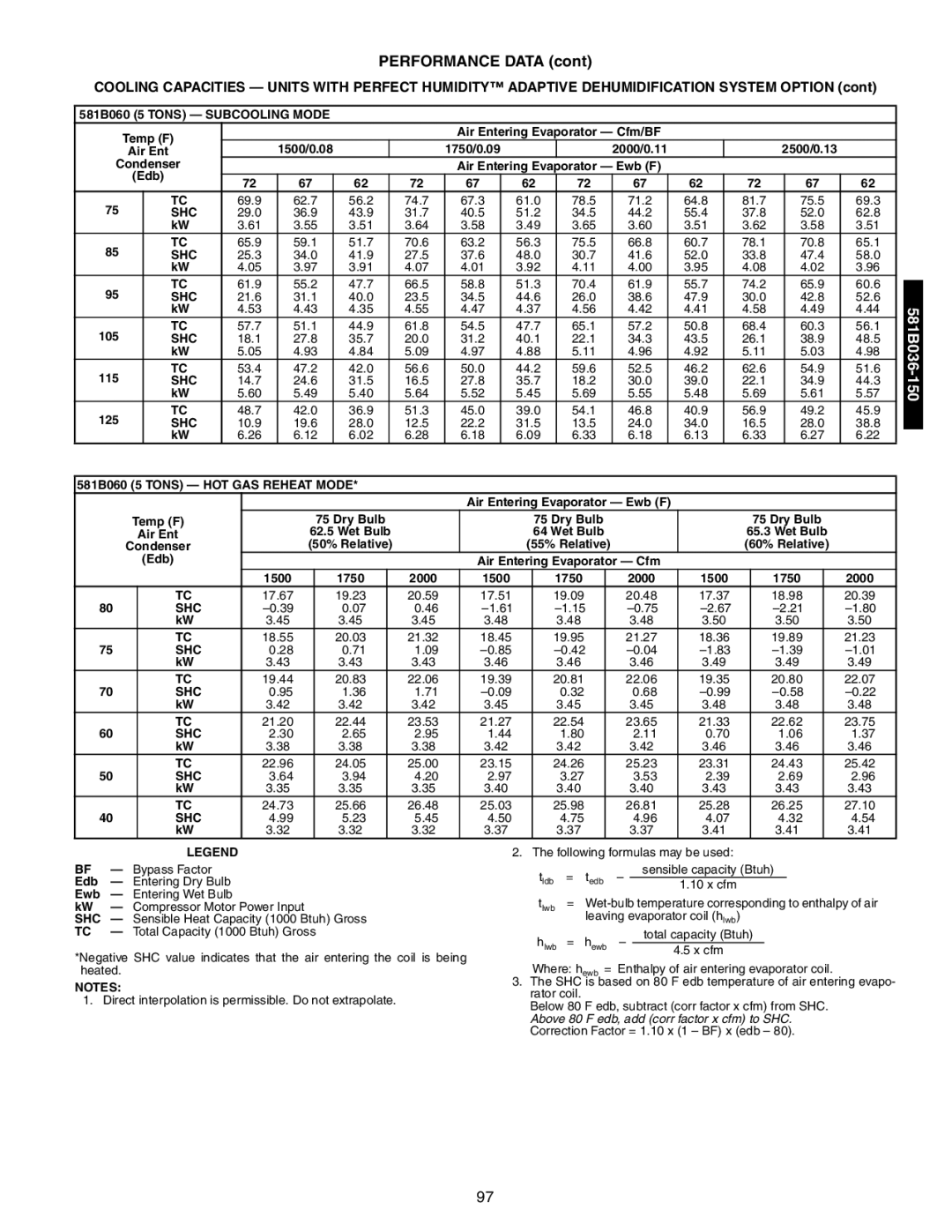

581B060 5 Tons HOT GAS Reheat Mode

581B060 5 Tons Subcooling Mode

1500/0.08

2500/0.13 Condenser Air Entering Evaporator Ewb F Edb

581B072 6 Tons HOT GAS Reheat Mode

581B072 6 Tons Subcooling Mode

581B036

581B090 71/2 Tons Subcooling Mode

AIR ENT

Condenser

581B102 81/2 Tons HOT GAS Reheat Mode

581B102 81/2 Tons Subcooling Mode

Wet Bulb Condenser

60% Relative Edb

581B120 10 Tons HOT GAS Reheat Mode

581B120 10 Tons Subcooling Mode

3000/0.03 3200/0.03

Condenser Air Entering Evaporator Ewb F

581B150 121/2 Tons HOT GAS Reheat Mode

581B150 121/2 Tons Subcooling Mode

3750 4300 5000 6250

581B048 3 Tons HIGH-STATIC Motor Belt Drive

581B036 3 Tons Standard Motor Belt Drive

General Notes for FAN Performance Data Tables

581B048 4 Tons HIGH-STATIC Motor Belt Drive

581B048 4 Tons Standard Motor Belt Drive

581B060 5 Tons Standard Motor Belt DRIVE* THREE-PHASE Units

581B060 5 Tons Standard Motor Belt DRIVE* SINGLE-PHASE Units

581B072 6 Tons Standard Motor Belt Drive

581B060 5 Tons HIGH-STATIC Motor Belt Drive

581B072 6 Tons HIGH-STATIC Motor Belt Drive

581B090 71/2 Tons Standard Motor Belt Drive

581B090 71/2 Tons HIGH-STATIC Motor Belt Drive

581B102 81/2 Tons Standard Motor Belt Drive

581B102 81/2 Tons HIGH-STATIC Motor Belt Drive

581B120 10 Tons Standard Motor Belt Drive

581B120 10 Tons HIGH-STATIC Motor Belt Drive

581B150 121/2 Tons Standard Motor Belt Drive

581B036 3 Tons HIGH-STATIC Motor Belt Drive

1300 675 277

Rpm Bhp Watts 1200 643 234 762

1400 707 326

1500 740 382

581B060 5 Tons Standard Motor Belt DRIVE* THREE-PHASE Units

581B072 6 Tons Standard Motor Belt Drive

1497

1074

2700 1280 1660

Cfm Rpm Bhp Watts 1800

581B090 71/2 Tons Standard Motor Belt Drive

581B090 71/2 Tons HIGH-STATIC Motor Belt Drive

581B102 81/2 Tons Standard Motor Belt Drive

581B102 81/2 Tons HIGH-STATIC Motor Belt Drive

878

818

907

917

581B120 10 Tons HIGH-STATIC Motor Belt DRIVE*

3900 705 1269 773 1503

1230

1239

5900

4600 807 1975

581B150 121/2 Tons Standard Motor Belt DRIVE*

581B150 121/2 Tons Standard Motor Belt Drive

Altitude COMPENSATION* 581B090-150

Altitude COMPENSATION* 581B036-072

Unit Motor Pulley Turns Open

Unit Sound Octave Bands Rating

Outdoor Sound Power Total Unit

Unit Size 581B EFFICIENCY%

Component CFM

129

Power Exhaust Amps AT 230 Mocp Size Fans Running

Power Exhaust Power Requirements

150 581B036

Performance Data 581B036-150

EVAPORATOR-FAN Motor Performance Standard Motor

Phase Continuous BHP

EVAPORATOR-FAN Motor Performance HIGH-STATIC Motor

Unit Maximum

090-150

036-072

FLA MCA Mocp LRA

Electrical Data 581B036-150 Units

121/2 Tons

581B036-150 Units

Sizes 036-150 581B090, 460-3-60 Shown

Typical Wiring Schematics 581B

EconoMi$er IV Wiring 581B036-150 Units

Typical Wiring Schematics 581B

EconoMi$er2 Wiring 581B036-150 Units

Non-Fused Disconnect Optional Sizes 581B036-150

Convenience Outlet Optional Sizes 581B036-150

Typical Piping and Wiring 581B036-150

580F036-151 and 581B036-150

Guide Specifications 580F036-151 and 581B036-150

Part 1 General

Part 2 Products

580F036-150 and 581B036-150

141

142

143

300

Physical Data 579F180-300

Unit 579F

Options and Accessories

Operating and Rigging Weights

Weight Adders

579F180-300

Unit STD Unit Economizer Corner DIM a DIM B DIM C Weight

Base Unit Dimensions 579F180,216

300-579F180

Base Unit Dimensions 579F240,300

Horizontal and Vertical Roof Curbs 579F180-300

Accessory Dimensions 579F180-300

PKG. NO. REF Curb Description Height CRRFCURB010A00

CRRFCURB011A00

Horizontal Supply/Return Adapter Installation 579F180-300

Accessory Dimensions 579F180-300

Barometric Relief/Power Exhaust

Accessory Curb Description Package no Height CRRFCURB013A00

Factory-Installed Convenience Outlet

Accessory Dimensions

Factory-Installed Non-Fused Disconnect

Selection Procedure With 579F180 Example

Performance Data 579F

Performance Data 579F

154

155

156

157

158

159

FAN Performance 579F180-300 Units

FAN Performance 579F180-300 Units

162

Altitude Compensation

Fan Performance Using Accessory Power Exhaust 579F180-300

Elevation Natural GAS Orifice SIZE†

Maximum Heating Value

ACCESSORY/FIOP Static Pressure in. wg* 579F180-300

Outdoor Sound Power

FAN RPM AT Motor Pulley Settings

Altitude Compensation 579F180-300

Maximum Unit

EVAPORATOR-FAN Motor Data

Acceptable Maximum

Continuous Operating AMP Draw BHP

579F180

Unit Nominal Voltage Compressor OFM IFM Power Combustion

Range Exhaust FAN Motor Supply

RLA LRA

579F240, 208/230 V Shown

Typical Wiring Schematics 579F

167

300 579F180

EconoMi$er IV Wiring 579F180-300 Units

Typical Wiring Schematics 579F

EconoMi$er2 Wiring 579F180-300 Units

IAQ -Indoor Air Quality SAT Supply Air Temperature

A48-6005

Non-Fused Disconnect Optional 579F180-300

579F180 Shown

Typical Piping and Wiring 579F180-300

NEC National Electrical Code

TXV

Physical Data 580F180-300

580F180-300

580F180

Base Unit Dimensions 580F180

174

Base Unit Dimensions 580F240

176

Base Unit Dimensions 580F300

300-580F180

Accessory Dimensions 580F180-240

Horizontal and Vertical Roof Curbs

580F180-240

178

Accessory Dimensions 580F300

Horizontal Supply/Return Adapter Installation 580F180-240

180

Selection Procedure With 580F240 Example

182

183

FAN Performance 580F180-300 Units

580F180360

FAN Performance 580F180-300 Units

580F180360*

7200 7500 580F180360*

186

Cfm Rpm Watts Bhp

580F240275 20 Tons

Bhp Rpm Watts 000

580F240275 20 TONS*

580F240360 20 TONS*

580F240360 20 Tons

000 500 10,000

580F180

Performance Data cont\

Unit Sound Weighted Octave Bands

Fan Performance Using Accessory Power Exhaust 580F180-300

Altitude Compensation 580F180-300

Elevation Maximum Heating Value

ACCESSORY/FIOP Static Pressure in. wg* 580F180-300

RLA LRA

Exhaust FAN Motor Supply

FLA LRA MCA Mocp

FLA

Typical Wiring Schematic 580F180, 460-3-60 Shown

Typical Wiring Schematics 580F

EconoMi$er2 Wiring 580F180-300

EconoMi$er IV Wiring 580F180-300

ECB

IAQ

Non-Fused Disconnect Optional 580F180-300

Typical Piping and Wiring 580F180-300

Unit 581A

Physical Data 581A155,180

581A155-300

Physical Data 581A210-300

Unit 581A

LOW Range

Physical Data

High Range

Options and Accessories 581A155,180 Weight Adders

Operating and Rigging Weights 581A155,180

Options and Accessories 581A210-300 Weight Adders

Unit

300-581A155

Base Unit Dimensions 581A155,180

202

Base Unit Dimensions 581A210-300

581A155,180

Accessory Dimensions 581A155,180

PKG. NO. REF Curb Height Description CRRFCURB010A00

ALL

Horizontal Supply/Return Adapter Installation 581A155,180

205

206

Accessory Dimensions 581A210-300

Determine NET Cooling Capacities

Selection Procedure

Entering WET-BULB F CFM

Cooling Capacities Standard Units

Cooling Capacities Standard Units

210

211

212

Cooling CAPACITIES, Units with HOT GAS Reheat Option

581A181 15 Tons Unit with HOT GAS Reheat in Cooling Mode

Cooling CAPACITIES, Units with HOT GAS Reheat Option

581A210 18 Tons Unit with HOT GAS Reheat in Cooling Mode

300

581A240 20 Tons Unit with HOT GAS Reheat in Cooling Mode

216

581A300 25 Tons Unit with HOT GAS Reheat a in REHEAT, B OFF

581A300 25 Tons Unit with HOT GAS Reheat in Cooling Mode

218

219

Available External Static Pressure in. wg Cfm

581A180 15 Tons Low Heat Units Airflow

7200 7500

581A180 15 Tons High Heat Units Airflow

7000

Rpm Watts Bhp 3500

8500

581A210 18 Tons Medium Heat Units*

581A210 18 Tons Medium Heat Units

224

Rpm Watts Bhp 000

581A240 20 Tons Medium Heat Units*

581A240 20 Tons Medium Heat Units

227

Rpm Watts Bhp 500

581A300 25 Tons Low Heat Units

10,500

11,000

12,500 581A300 25 Tons Medium Heat Units*

581A300 25 Tons Medium Heat Units

11,000 11,500 12,000 12,500

581A300 25 Tons High Heat Units

581A210 18 Tons Low Heat Units*

581A210 18 Tons Low Heat Units

581A210 18 Tons Medium Heat Units*

581A210 18 Tons High Heat Units*

581A210 18 Tons High Heat Units

581A240 20 Tons Low Heat Units*

581A240 20 Tons Low Heat Units

581A240 20 Tons Medium Heat Units*

581A240 20 Tons High Heat Units*

581A240 20 Tons High Heat Units

581A300 25 Tons Low Heat Units*

12,000 12,500

581A300 25 Tons Medium Heat Units*

581A300 25 Tons Medium Heat Units

581A300 25 Tons High Heat Units*

Altitude Compensation 581A210-300

Altitude COMPENSATION* 581A155,180

Altitude Compensation 581A155,180

FAN RPM AT Motor Pulley SETTINGS* 581A155,180

ACCESSORY/FIOP Static Pressure in. wg* 581A155,180

Indoor Sound Data Total Unit 581A155,180

Evaporator FAN Motor Performance 581A155,180

Unit ARI Weighted Octave Bands Rating

FAN RPM AT Motor Pulley SETTINGS* 581A210-300

Drive Motor Pulley Turns Open

ACCESSORY/FIOP Static Pressure in. wg 581A210-300

Evaporator FAN Motor Specifications 581A210-300

Unit Drive Orientation Motor Nominal Voltage MAX Efficiency

Watts BHP

Electrical Data 581A155,180

Electrical Data 581A

FLA

Hacr

Electrical Data 581A210-300 Without Convenience Outlet

581A155

246

581A155, 460-3-60 Shown

Typical Wiring Schematics 581A

EconoMi$er2 Wiring 581A155,180

EconoMi$er IV Wiring 581A155,180

Typical Piping and Wiring 581A 581A155 Shown

579F/580F/581A155-300

251

252

253

254

581A210-300

Guide Specifications 581A210-300 Units

Guide Specifications 581A210-300 Units

257

258

Operating SEQUENCE, Size 036-151 Units

Controls

Heating, Units With Economizer

Controls

Heating, Units Without Economizer

Operating SEQUENCE, 581A210-300

262

Application Data

Wiring of Outdoor-Air Thermostat

Condenser Coil Protection

Concentric Duct Details

Application Data

Condenser Coil Protection Applications

Concentric Duct Distribution Concentric Duct Details

265

Economizer Changeover Curves

ECONOMI$ER IV Sensor Usage Chart

Enthalpy Sensor

267

Index

Specifications Subject to Change Without Notice