Page

Page

Page

Preface

Page

Table of Contents

Digital Keypad Operation and Start Up

Troubleshooting

Parameters

Appendix a Specifications Appendix B Accessories

Fault Code Information and Maintenance

Appendix C How to Select the Right AC Motor Drive

Introduction

Receiving and Inspection

Example for 5HP/3.7kW 3-phase 230V AC motor drive

Nameplate Information

Model Explanation

Drive Frames and Appearances

Series Number Explanation

5HP/0.75-3.7kW Frame B 15HP/5.5-11kW Frame C

15-30HP/11-22kW Frame D 40-100HP/30-75kW Frame E

Preparation for Installation and Wiring Ambient Conditions

Storage

Operation

Transportation

Remove Keypad

Remove Front Cover

Step

Lifting

Dimensions

Introduction

Introduction

Introduction

Frame E

This page intentionally left blank

Installation and Wiring

RL1 UT1 SL2 VT2 TL3 WT3

Wiring

For models of VFD-VE Series 20HP/15kW and above

FWD REV MI1 MI2 MI3 MI4 MI5 MI6 DCM

External Wiring

Main Circuit Main Circuit Connection

+2/B1

NFB

Brak e res istor

Motor

Terminals +1, +2 for connecting DC reactor

Mains power terminals R/L1, S/L2, T/L3

Output terminals for main circuit U, V, W

Forward running

Refer to Appendix B for the use

+2/B1 Brake resistoroptional Brake unitoptional

Spec ial braking resis tor/unit

Grounding terminals

Main Circuit Terminals

Models Wire Torque Wire Type

Control Terminals

Position of the Control Terminals

OFF

FWD

DFM

MRA

MCM

Terminal Terminal Function Factory Settings Sink

MO1

MO2

ACM

AFM

Analog input terminals AVI, ACI, AUI, ACM

AVI/ACI/AUI ACM

General

Frame Torque Wire

AWG 0.3-2.1mm

Page

Descriptions

Display Message

Display Message Descriptions

External Fault

Displays the selected parameter

Displays the actual stored value of the selected parameter

Start

How to Operate the Digital Keypad KPV-CE01

To copy parameters

Reference Table for the LCD Display of the Digital Keypad

Dimension of the Digital Keypad

LCD

Operation Method

External signal

Start-up Preparations before Start-up

Communication Communication address definition

JOG

Check following items

Trial Run

Digital Keypad Operation and Start Up

This page intentionally left blank

Parameters

Parameter can be set during operation

Summary of Parameter Settings

Group 0 System Parameters

Time Unit for Unit 0.01 second 00-14

Group 1 Basic Parameters

01-36 1st Output Voltage 230V 0.1V~255.0V

RUN/STOP, REV/FWD

Group 2 Digital Input/Output Parameters

MOA

Width of the Desired

AUI

Group 3 Analog Input/Output Parameters

~200.0% 100.0

Group 4 Multi-Step Speed Parameters

Group 5 Motor Parameters

Group 6 Protection Parameters

Parameters

06-28 Electronic Thermal 30.0~600.0 sec

Speed Search 07-10 Base-block Speed Stop operation

Group 7 Special Parameters

07-29 High Torque Offset

Group 8 High-function PID Parameters

08-32 Tension PID P2

100.0 Feedback

Group 9 Communication Parameters

09-20 Block Transfer

Group 10 Speed Feedback Control Parameters

Explanation Settings

Group 11 Advanced Parameters

Version

Version Differences

Crane function

Low-voltage during constant speed

Version Group 0 System Parameters

Version 2.02, the parameters are from Pr.08-00 to Pr.08-15

New settings 44~50 for Pr.02-00~Pr.02-06 and new parameter

02-35 Multi-function Output

Setting Reserved 02-43 Zero-speed Level ~65535 rpm Motor

05-03 Rated speed of Motor

Setting 08-00 Input Terminal for PID No function Feedback

PID

Switch Level for Smart ~100.0% according to Pr.08-26

Setting 10-04 ASR Auto Speed

00-00

Description of Parameter Settings

00-01

00-03

Factory setting

Start-up Display Selection

00-04

00-04Content of Multi-Function function Display Settings

MO2 MO1 MRA

MI9 MI8 MI7 MI6 MI5 MI4 MI3 MI2 MI1 REV FWD

00-07

00-06

00-08

00-08 00-07

No password set or successful input in Pr

00-09

Factory setting 100%

Energy Saving Gain Unit

00-10

Optimal Acceleration/Deceleration Setting

Settings Constant Torque 100% Variable Torque 125%

00-12

Constant/Variable Torque Selection

00-15 00-16

00-14

00-17

230V/460V Series

Auto Voltage Regulation AVR Function

00-18

00-19

Auto Energy-saving Operation

Stop Method Factory setting

Source of the Master Frequency Command Factory setting

Settings Ramp to stop Coast to stop

00-20

Reverse Operation

00-23

01-01

01-00

01-35

01-02

01-37

01-04

01-38

01-05

01-41

Settings 00~600.00Hz

01-42

01-09

Pr.01 =Fl ow =Fc md

FcmdFmi n Pr.01

60Hz =Fl ow

Flow

Output Frequency Upper Limit Unit

01-10

01-11

Output Frequency Lower Limit Unit

01-13

01-12

01-14

01-15

01-23

01-22

01-24 01-25 01-26

01-28

01-27

01-29

01-30

Fout 01-34=0 01-34=1 01-34=2 Fmin 01-07 Frequency command

02-00 Control Circuits of the External Terminal

RUN/STOP, REV/FWD

FWD/STOP

REV/STOP

02-30

Multi-Function Input Command

Parameters

As long as the ON/OFF status is restored, the speed-tracing

Settings Functions Descriptions

JOG are included. Refer to Pr -00~04-29

Function could still be operated

Command form ACI Force to be ACI Operation speed

Command form AVI Force to be AVI Operation speed

OFF FOC+PG speed control mode

When it is ON, the drive will operate by 1st V/f

Enable multi-step

Execute position control

Enable position control

Motor Frequency 10-19 Feedbac k 10-00 10-01

RUN

Change from speed command to position command. It is

When this function is enabled, the pulse of PG card will

Serial position input

UP/DOWN Key Mode

02-07

02-10

02-09

MI9 MI8 MI7 MI6

MI4 MI3 MI2 MI1 REV

02-14

02-13

02-35

02-36

Settings Functions Descriptions

Indication Baseblock Active when the warning is detected

Settings Functions Descriptions

When the error between PID target value and PID feedback

It will be OFF when brake delay time exceeds Pr.02-31

For error treatment of tension PID feedback

Speed Attained

02-15

Reserved Example of crane function

Multi-output Direction Unit1

02-17

02-16

02-19

02-18

02-20

02-21

Settings 000~65.000 Sec

Brake Delay Time Unit0.001

Output Current Level Setting for External Terminals Unit1

02-31

02-34

02-33

02-43

03-01

03-00

03-02

03-04

03-03

03-05

03-10

03-09

03-11

03-12

03-15

03-14

03-16

03-17

~20mA=0~100%

~10V=0~100%

10~10V=0~100%

03-22

03-19

03-25

03-20

04-01

04-00

04-02

04-03

MI4 MI3 MI2 MI1

05-00

05-02

05-01

05-03

05-04

05-07

05-06

05-10

05-12

Connection is finished Connection control

Full-load Current of Motor Unit 1%

05-13

05-14

05-15

05-18

05-17

05-19

05-22

05-25

05-24

05-26

05-27

05-31

05-29

05-32

Low Voltage Level Unit

06-00

06-01

Over-Voltage Stall Prevention Unit

06-03

06-02

06-04

06-06

06-05

Over-torque Detection Selection OT1

06-07

06-11

06-10

06-13

06-12

06-14

06-28

06-15

Load

06-16

Parameters

06-23

Fault code Bit0 Bit1 Bit2 Bit3 Bit4 Bit5 Bit6 Current Volt

06-24

06-25

Revision August 2008, 03VE, SW 103

External fault input EF

Fault code Bit0 Bit1 Bit2 Bit3 Bit4 Bit5 Bit6

ACE

Connection

PTC Positive Temperature Coefficient Detection Selection

06-29

06-30

06-32

06-31

06-33

06-34

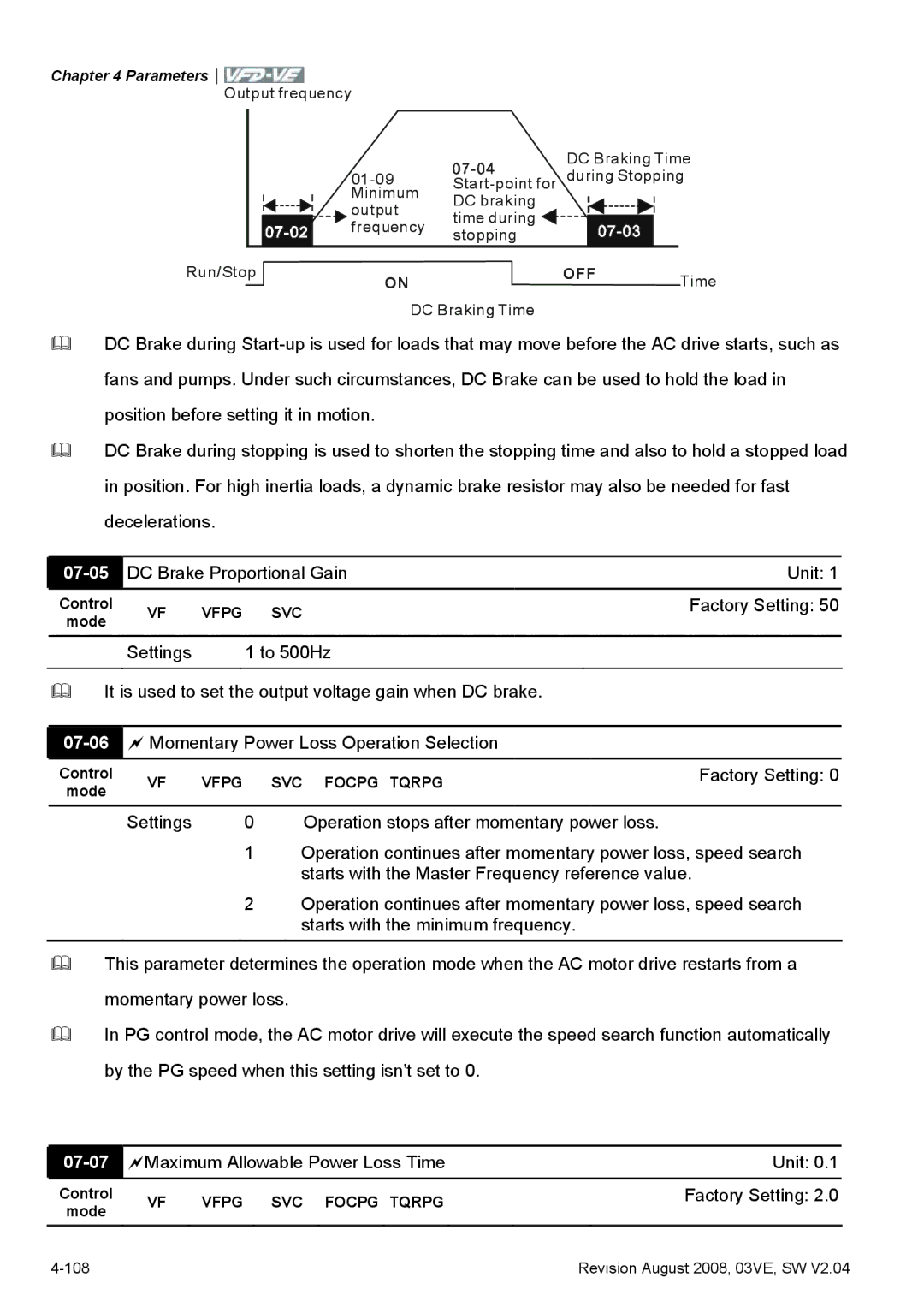

07-01

07-00

07-02

07-03

Maximum Allowable Power Loss Time Unit

Momentary Power Loss Operation Selection

07-06

07-07

Baseblock Time for Speed Search BB Unit

07-08

Current Limit for Speed Search Unit

07-09

07-10

Auto Restart After Fault Unit

07-11

07-12

07-13

Decel. Time Selection for Momentary Power Loss DEB function

07-14

DEB Return Time Unit

Status 2 unexpected power off, such as momentary power loss

07-16

07-15

07-17

07-18

07-21

07-20

07-22

07-23

07-26

07-25

07-27

07-29

07-28

07-30

07-31

Emergency Stop EF & Forced Stop Selection

07-36

08-02

08-01

08-04

08-03

08-05

08-06

08-08

Feedback Signal Detection Time Unit

08-09

To 3600.0 sec

08-10

08-11

08-14

08-13

08-15

08-16

Line speed, speed mode

Open-loop, torque mode

08-23

08-22

08-24

08-26

08-28

Auto-tuning Tension PID

08-29

Tension PID P1 Unit

08-31

08-30

08-32

08-33

DCM AB2

DFM DCM

08-38

08-39

08-40

Settings To 3000.0 m/min

Pulse Number for Each Meter Unit

08-41

08-44

08-43

08-46

08-47

08-51

08-50

08-52

08-54

08-58

08-57

08-62

08-67

08-64

08-68

08-69

08-75

08-71

08-77

08-78

08-84

08-83

08-85

08-86

Communication Address

09-00

09-01

09-02

Ascii mode

Settings Modbus Ascii mode, protocol 7,N,1

09-03

09-04

STX

RTU mode

Start

Data

END

F7H

6FH

0FH

A0H

Content

Address ‘0’ ‘1’ Function ‘3’ Starting data address ‘4’

00B No function

Jog + Run

Ascii mode RTU mode

Command F

A1H

C3H

Code

09-06

09-05

09-07

09-08

09-10

09-09

09-11

09-12

09-15

09-14

09-16

09-17

10-00

Group 10 PID Control

Encoder Pulse

Fwdrev

10-03

10-02

10-04

10-05

10-10

10-09

10-12

10-14

10-13

10-15

FWD REV

10-17

10-16

10-18

10-19

10-21

10-20

10-22

10-23

10-27

10-26

10-28

10-29

Control Diagram fo r the Torque + Encoder

Speed

System Control

11-00

YES

11-02

11-01

11-03

11-11

Gain Value of Flux Weakening Curve for Motor Unit

11-05

11-07

11-06

11-08

11-09

11-13

11-12

11-14

11-15

11-18 APR Gain

11-17

11-19

11-20

Revision August 2008, 03VE, SW 165

Page

Over Current OC

Troubleshooting

Ground fault

Ground Fault

Over Voltage OV

Low Voltage Lv

Suitable power

Over Heat oH1, oH2, oH3

Reduce load or increase the power of AC motor drive

Overload

OL1/ OL2

Display of KPV-CE01 is Abnormal

Phase Loss PHL

Yes

Motor cannot Run

Motor Speed cannot be Changed

Motor does not Run as Expected

Motor Stalls during Acceleration

Environmental Condition

Electromagnetic/Induction Noise

Affecting Other Machines

Common Problems and Solutions

Fault Code Information

Phase Loss

Ground fault Not for protection of the user

Provided for AC motor drive protection

Heatsink

Igbt overheating

Overheating

Motor overheating

Phase error

Isum error

OC hardware error

OV hardware error

Brake resistor fault

Password is locked

Connection switch

Error

When slip exceeds

Reset

It will be displayed

Decrease the load if overload

Daily Inspection

Maintenance and Inspections

Periodic Inspection

Keypad Maintenance Check Items Methods and Criterion

Voltage Maintenance Check Items Methods and Criterion

One

Daily

Check Items Methods and Criterion

Change of copper plate

Visual, aural inspection and smell Or peculiar smell

Change fan Overheat

This page intentionally left blank

Appendix a Specifications

± 5%

Applicable

All Brake Resistors & Brake Units Used in AC Motor Drives

Model Vfdb Model and No. Torque

BR1K2W6P8

Prevent damaging the brake resistor

Decrease accordingly. Suggested cycle time is one minute

VFD Series

Dimensions are in millimeter

Dimensions and Weights for Brake Resistors

Order P/N BR500W030, BR500W100, BR1KW020, BR1KW075

Specifications for Brake Unit

Dimensions are in millimeterinch

Dimensions for Brake Unit

189.5 200.0

VFDB4132

Phase

No-fuse Circuit Breaker Chart

Smaller fuses than those shown in the table are permitted

Fuse Specification Chart

Model Line Fuse Input Output Bussmann P/N

VFD007V23A-2 JJN-10 VFD007V43A-2

AC Output Reactor Recommended Value

AC Reactor AC Input Reactor Recommended Value

Impedance

37.5 52.5 18.5 67.5 82.5 120 100 150 130 195

37.5 52.5 18.5 67.5 120 100 150 130 195 160 240

Fundamental Max Inductance mH Continuous Amps

May damage the mains circuit

Applications for AC Reactor

Silicon rectifier Powerreactor AC motor drive Reactor Motor

Diagram a

Zero Phase Reactor RF220X00A

Diagram B

Nominal Method

Input voltage DC Amps Inductance mh

DC Choke Recommended Values

AFM ACM AVI

Remote Controller RC-01

+10V

DCM MI5 FWD REV JOG VFD-VE

ABZ1

PG Card for Encoder EMV-PG01X

PG1 PG2

300m

70m Basic Wiring Diagram wiring

12V

Types of Pulse Generators Encoders

Voltage

EMV-PG01O

Terminal Descriptions Symbols

Types of Pulse Generators

PG OUT

Wire Gauge 25mm2 AWG16 or above Basic Wiring Diagram

Z1, Z1 Phase or 2-phase input. Maximum 300kP/sec A2, A2

70m

EMV-PG01O

Voltage

Z1, Z1 Phase input. Maximum 300kP/sec

Power source of EMV-PG01L

EMV-PG01L

Output Voltage +5V ±5% 200mA

Wire Gauge 25mm2 AWG16 or above Basic Wiring Diagram wiring

ABZ1 AB2

Complementary

AC Drives Model Number FootPrint

AMD-EMI Filter Cross Reference

10TDT1W4C

26TDT1W4C

Saddle on both ends Saddle on one end

Choose suitable motor cable and precautions

„ For models 5hp/3.7kW and less

Insulation level of motor 1000V 1300V 1600V

1000V 1300V 1600V 460VAC input voltage

230VAC input voltage

Appendix B Accessories

Order P/N RF015B21AA / RF022B43AA

Dimensions are in millimeter and inch

302 315

Order P/N RF022B21BA / RF037B43BA

Order P/N RF110B43CA

Order P/N 10TDT1W4C Order P/N 26TDT1W4C

Order P/N 50TDS4W4C Order P/N 100TDS84C

Order P/N 200TDDS84C Order P/N 150TDS84C

Order P/N 180TDS84C

Multi-function I/O Extension Card Functions

Power

Terminals Description

SO1-MCM

Terminals

SO2-MCM

MI7~MIB

Dimensions Wiring

This page intentionally left blank

Page

Capacity Formulas

Related Specification

Speed Time Overload Starting Torque Ratings

When one AC motor drive operates more than one motor

When one AC motor drive operates one motor

Starting capacity=

⋅ IM ≤ the rated current of AC motor drive a

General Precaution

Selection Note

Parameter Settings Note

Standard motor

How to Choose a Suitable Motor

Special motors

Power Transmission Mechanism

Pole-changing Dahlander motor

Motor torque

Motor

This page intentionally left blank