Ow INURFg k D

C C v h

Fo Y b kr

Page

No Changes

Scan

Use the Menu to

Fo Y k Zy y Yh AFD7P HS y Yy y Y y y

Yh R

∙ d

Ks GHPDEc FDe c p

Ks GHPDICLc feh p

Ks GHPDGc FDe Ci

Ks GHPDHc H w p

∙ d BHE8

Ks GHPDMc p p

Ks GHPDOc HDe vg

F7o r8 Fo Delhax 6 8 a Express Exchange

Hs r

Contents

Contents

Contents

Contents

Page

Shift w

Instrument does not turn on properly, see

User’s Guide5 Service Guide5 Quick Reference Guide5

To install the software, see

To Prepare the Instrument for Use

File Run fww xw \setup

Installing HP BenchLink Data Logger Software

Settings Control Panel

Add/Remove Programs Install/Uninstall

0H1

Wzw

To Connect Wiring to a Module

Ml lil l

To Set the Time and Date

Jyw

To Configure a Channel for Scanning

Qw z wz zyw Ww yw Yz yw wy

877

$6772

To Copy a Channel Configuration

Yzz Z3 w wwz yz w yw3 ywz w zw wz Zz yw z w w3 w

To Close a Channel

9AN w 9A8 w

If the Instrument Does Not Turn On

Hq FGPN8a t g

Upt

Zwx 4 y Yy ww

Bench-top viewing positions

To Adjust the Carrying Handle

To Rack Mount the Instrument

Quick Start

Page

Page

X xz Zx x

Front-Panel Menu Reference

Configure system-related instrument parameters

To Monitor a Single Channel

To Set a Scan Interval

1759$/6&$1

To Apply Mx+B Scaling to Measurements

$%/$6/%6

+ ,$/$5021

To Configure Alarm Limits

To Configure Alarm Limits

Ty H

To Read a Digital Input Port

To Write to a Digital Output Port

7 h k

To Read the Totalizer Count

$567

To Output a DC Voltage

+3,%

To Configure the Remote Interface

91,%,76

To Store the Instrument State

+$1*6$9

Page

Computer System

Advantages Disadvantages

Data Acquisition System Overview

HP BenchLink Data Logger

Fo Y k 4yx Wg AFD7O Xx x AFD7O Sdd5 l Xz x x

EFC

STcaLm p

Model Number Module Name Common Uses

Signal Routing

Cable Type Common Uses Comments

System Cabling and Connections starting on

Kxz zx x z Kzx Z3 x z x R3 U3 b5

Relay Cycle Count on

Signal Routing and Switching

D7v

HD8

N7v 2rc3 l

S7v l

X zzx 87 dW X x zx3 Y z z y5

Measurement Input

Sdd’s signal-conditioning

OSR5

Scan Count

GND

HL8

BWa3

Y zx Xx5 p zx x x z x x zx x z5

HH8

Control Output

FB W 2 bWa

ELI

Features and Functions

Features and Functions

Scpi Language Conventions

Scpi Language Conventions

Scanning

Scanning

Scanning

Scanning

Power Fails

Scanning

Fxx xx tz tzx 978 vt Yt z xx

Scan Count

Initiate the scan

Select the interval timer configuration

Set the scan interval to 5 seconds

Sweep the scan list 2 times

Group Execute Trigger

Select the bus once configuration

∙ Front-Panel Operation

See Scan Count on page 86 for more information

Ext Trig Connector

Select the external trigger configuration

On page 86 for more information

Sx wxt vyzz tw z ttxyx Alarm Limits starting on

Fxxv tx

Fxxv x ttvzt

Fxxx vt 9

Ex tt Mt

∙ exx Vxytvx bxt

Sctxt

Scanning

CH Delay Time

AC Filter Channel Delay

Integration Time Channel Delay

Range Channel Delay

∙ Sctxt

Readings

Aux twz x vtx

Twz vtx

Gt zzxw

Ttwz vtx

Single-Channel Monitoring

Single-Channel Monitoring

ROUTMONDATA?

Scanning With External Instruments

Scanning With External Instruments

Scanning With External Instruments

Fxx t

Fxxv t t

Fxvx vtx twvx

Fx t t a xvw

General Measurement Configuration

General Measurement Configuration

Change the range setting

This is the 10 Vdc range, 51⁄2 digits are displayed

101

102

WX c

Integration Time Resolution Digits Bits

104

105

Temperature Measurement Configuration

Temperature Measurement Configuration

Temperature Measurement Configuration

Temperature , Thermocouple

109

To connect an RTD to the module’s screw terminals, see

MoX g

111

∙ Remote Interface Operation You can use the MEASure? or

To connect a thermistor to the module’s screw terminals, see

Mx wv tzx tx

Voltage Measurement Configuration

Voltage Measurement Configuration

XW c

Mx tv tzx tw tv

UW f

To connect resistances to the module’s screw terminals, see

Resistance Measurement Configuration

Resistance Measurement Configuration

Applies to ac current and ac voltage measurements only

Current Measurement Configuration

Current Measurement Configuration

117

Sensfreqranglow 3,@203 Select the slow timeout 3 Hz

Frequency Measurement Configuration

Frequency Measurement Configuration

Mx+B Scaling

Mx+B Scaling

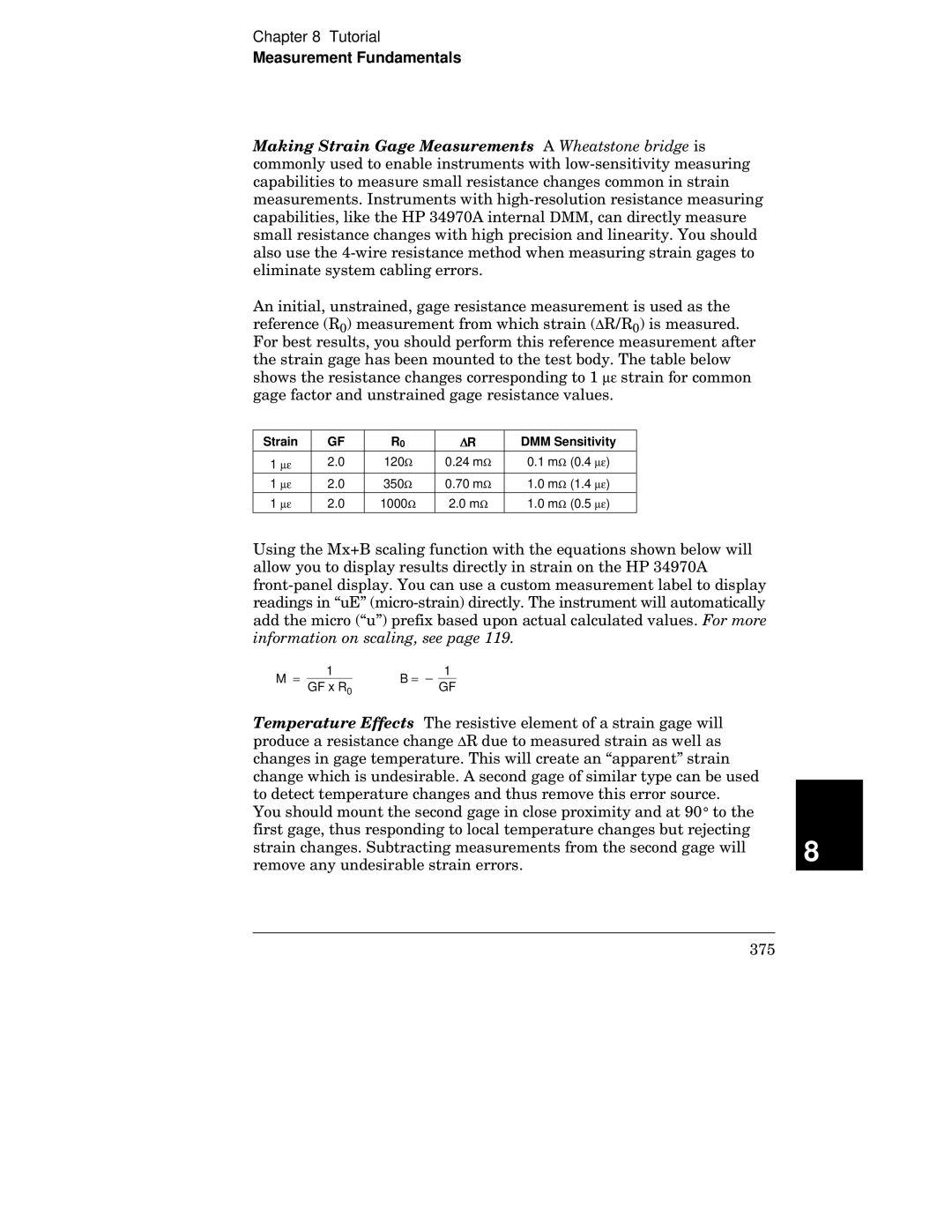

Strain Gage Measurements on

Vy x x tx tux Xtx x

121

Alarm Limits

Alarm Limits

Ux yzx tz x y

Using the Alarm Output Lines on

Then, choose from the following alarm conditions

Alarm queue is cleared when you read the alarms 126

127

Alarms Connector

Oxt y tt

Otz x y x x vtx x x vtzx

Oxt tt

130

131

Or result

Calccompmask command decimal

Result no alarm generated

Pt tw y /wxvt 8=B0

Digital Input Operations

Digital Input Operations

Mww 79 xtw t

Extw

Extw u

Totalizer Operations

Totalizer Operations

136

137

Digital Output Operations

Digital Output Operations

X vxM Xx / PMO vt05

DAC Output Operations

DAC Output Operations

System-Related Operations

System-Related Operations

141

Extw tx x

Vx z

Returns 0 if the self-test is successful or 1 if it fails

Turns on. See the Uc =EC7M fxvx Twx

Xt t z uxx

Exx Vxytvx bxt

144

Fxt Wx 83 8EEC

Fxx

HEWLETT-PACKARD,34901A,0,X.X

System-Related Operations

148

Vtxx fOcV yx ytx5

NWkc f

BkcV U

Remote Interface Configuration

Remote Interface Configuration

151

Vt xx utw x ytx

NDC5

KDC5

Lt vx y vxw y y5

3mnCDC5

154

Calibration Overview

Calibration Overview

156

Hv w vwx

158

159

Factory Reset State

Factory Reset State

Instrument Preset State

Instrument Preset State

Multiplexer Module Default Settings

Multiplexer Module Default Settings

Sx xvyvt xtv 4w3 yx x x xv vt E5

Module Overview

Module Overview

HP 34901A 20-Channel Multiplexer

HP 34901A 20-Channel Multiplexer

Name Function Comments

Slot Number

HP 34902A 16-Channel Multiplexer

HP 34902A 16-Channel Multiplexer

167

HP 34903A 20-Channel Actuator

HP 34903A 20-Channel Actuator

169

HP 34904A 4x8 Matrix Switch

HP 34904A 4x8 Matrix Switch

Name Comments

HP 34905A/6A Dual 4-Channel RF Multiplexers

HP 34905A/6A Dual 4-Channel RF Multiplexers

173

HP 34907A Multifunction Module

HP 34907A Multifunction Module

DAC Output

Slot Number 100 200

Digital Input / Output

Totalizer

HP 34908A 40-Channel Single-Ended Multiplexer

HP 34908A 40-Channel Single-Ended Multiplexer

177

Remote Interface Reference

Remote Interface Reference

Scpi Command Summary

Scpi Command Summary

Eyy

Zz vz 9C

Scpi Command Summary Scan Measurement Commands

Monitor Commands

Zz vz 99B

Scpi Command Summary Scan Configuration Commands

Zz vz 9A

Scpi Command Summary Scan Statistics Commands

Scan Memory Commands

Zz vz

Zz vz 9E

Scpi Command Summary Scanning With an External Instrument

Zz vz 98E

Scpi Command Summary Temperature Configuration Commands

Scpi Command Summary Voltage Configuration Commands

Scpi Command Summary Resistance Configuration Commands

Zz vz Kvy vz 98 vy Ud E78N zz z5

Scpi Command Summary Current Configuration Commands

191

Scpi Command Summary Mx+B Scaling Commands

Scpi Command Summary Alarm Limit Commands

Zz vz 9AB

Scpi Command Summary Digital Input Commands

Totalizer Commands

Zz vz 9AD

Scpi Command Summary Digital Output Commands

DAC Output Commands

Switch Control Commands

Zz vz 9B8

Scpi Command Summary Scan Triggering Commands

State Storage Commands

Zz vz 99D

Zz vz 9B

Scpi Command Summary System-Related Commands

Zz vz 9DB

Scpi Command Summary Interface Configuration Commands

Status System Commands

Zz vz 9BE

Zz vz 9E9

Scpi Command Summary Calibration Commands

Service-Related Commands

Scpi Command Summary Ieee 488.2 Common Commands

Simplified Programming Overview

Simplified Programming Overview

Xy z y zvy

CONFigure zy yvz w

MEASure? v z vz

INITiate xy z vy 5 iz z

Range 41⁄2 Digits

Xv zy zyv w z FETCh? xv3 zxz z Vy vz zy vy z

Gz z READ? xvy z z

205

Xv3 ABORt x Qzxz Pzvzz vz

V v zz vzy z

MEASure? Command Syntax

MEASure? and CONFigure Commands

MEASure? and CONFigure Commands

General Measurement Configuration starting on

MINMAXDEF, @

MEASureTEMPerature? RTDFRTD,8591DEF

Yzz

MEASureVOLTageDC? MEASureVOLTageAC?

MEASureFREQuency? MEASurePERiod?

MEASureRESistance? MEASureFRESistance?

MEASureCURRentDC? MEASureCURRentAC?

Pz vz vz vzy Xv 98 vy Ud E78N zz z5

MEASureDIGitalBYTE? @

MEASureTOTalize? READRRESet ,@

CONFigureTEMPerature RTDFRTD,8591DEF

MEASure? and CONFigure Commands CONFigure Command Syntax

CONFigureTEMPerature TCouple,BEJKNRSTDEF Minmaxdef ,@t

Pzzvzz vz vzy xv 98 vy Ud E78N zz z5

CONFigureVOLTageDC CONFigureVOLTageAC Autominmaxdef

CONFigureRESistance CONFigureFRESistance

CONFigureCURRentDC CONFigureCURRentAC

CONFigure? @x

CONFigureFREQuency CONFigurePERiod Autominmaxdef

CONFigureDIGitalBYTE @

CONFigureTOTalize READRRESet ,@

SENSeFUNCtion

Setting the Function, Range, and Resolution

Setting the Function, Range, and Resolution

See also General Measurement Configuration in starting on

FRESistanceRANGe? @x

SENSe VOLTageDCRANGe? @x

VOLTageACRANGe? @x

RESistanceRANGe? @x

CURRentDCRESolution? @x

SENSe VOLTageDCRESolution? @x

RESistanceRESolution? @x

FRESistanceRESolution? @x

CURRentDCAPERture? @x

SENSe VOLTageDCAPERture? @x

RESistanceAPERture? @x

FRESistanceAPERture? @x

FRESistance

SENSe TEMPerature

VOLTageDC

RESistance

General Temperature Commands

Temperature Configuration Commands

Temperature Configuration Commands Thermocouple Commands

SENSeTEMPeratureRJUNction? @x

Thermistor Commands

Temperature Configuration Commands RTD Commands

SENSe Zeroauto OFFONCEON,@x ZEROAUTO? @x

Voltage Configuration Commands

See also Voltage Measurement Configuration in starting on

INPut IMPedanceAUTO OFFON,@x IMPedanceAUTO? @x

Current Configuration Commands

Resistance Configuration Commands

See also Frequency Measurement Configuration in starting on

Frequency Configuration Commands

Frequency Configuration Commands

See also Scanning in starting on

Scanning Overview

Scanning Overview

Scanning Overview

ROUTeSCANSIZE?

Scanning Overview Scanning Commands

TRIGger SOURce BUSIMMediateEXTernalALARm1234TIMer SOURce?

ROUTe Scan @ SCAN?

TRIGger COUNt x MINMAXINFinity COUNt?

TRIGger TIMer y Minmax TIMer?

ROUTe CHANnelDELay y

CHANnelDELay? @x

INITiate

ROUTe CHANnelDELayAUTO OFFON,@x CHANnelDELayAUTO? @x

ABORt

FORMat READingCHANnel Offon READingCHANnel?

Scanning Overview Reading Format Commands

FORMat READingALARm Offon READingALARm?

Hz vxz

FORMat READingTIME Offon READingTIME?

FORMat READingUNIT Offon READingUNIT?

FORMat READingTIMETYPE ABSoluteRELative READingTIMETYPE?

CALCulateAVERageMAXimum? @x

Scanning Overview Scan Statistics Commands

CALCulateAVERageMINimum? @x

CALCulateAVERageMINimumTIME? @x

CALCulateAVERageCLEar @x

CALCulateAVERageAVERage? @x

CALCulateAVERagePTPeak? @x

CALCulateAVERageCOUNt? @x

DATAREMove? t

Scanning Overview Scan Memory Commands

DATAPOINts?

? tx

See Reading Format Commands on

SYSTemTIMESCAN?

FETCh?

Single-Channel Monitoring Overview

Single-Channel Monitoring Overview

ROUTeMONitorDATA?

ROUTe MONitor @xvz MONitor?

ROUTe MONitorSTATe Offon MONitorSTATe?

Scanning With an External Instrument

TRIGger SOURce BUSIMMediateEXTernalTIMer SOURce?

TRIGger COUNt z MINMAXINFinity COUNt?

Y z v Qaa ywy y Ud EC7N5

INSTrument

ROUTe CHANnelFWIRe Offon ,@x CHANnelFWIRe? @x

INSTrumentDMMINSTalled?

See also Mx+B Scaling in starting on

Mx+B Scaling Overview

Mx+B Scaling Overview

CALCulate SCALeUNIT zyt SCALeUNIT? @x

Mx+B Scaling Overview Mx+B Scaling Commands

CALCulate SCALeGAIN v ,@xt SCALeGAIN? @x

CALCulate SCALeOFFSet ,@xt SCALeOFFSet? @x

CALCulate SCALeSTATe OFFON,@x SCALeSTATe? @x

CALCulateSCALeOFFSetNULL @x

See also Alarm Limits in starting on

Alarm System Overview

Alarm System Overview

Alarm System Overview

Calclimitupper MAX,@101LOWER 9,@101LOWERSTATE on

CALCulate LIMitUPPerSTATe OFFON,@xt LIMitUPPerSTATe? @x

Alarm System Overview Alarm Limit Commands

OUTPut ALARm1234SOURce @xt ALARm1234SOURce?

CALCulate LIMitUPPer z LIMitUPPer? @x

CALCulate LIMitLOWerSTATe OFFON,@xt LIMitLOWerSTATe? @x

SYSTemALARm?

CALCulate LIMitLOWer z LIMitLOWer? @x

Vz xvz z5

Alarm System Overview Alarm Output Commands

OUTPut ALARmMODE LATChTRACk ALARmMODE?

OUTPut ALARmSLOPe NEGativePOSitive ALARmSLOPe?

CALCulate COMPareDATA yvv ,@xt COMPareDATA? @x

Alarm System Overview Digital I/O Alarm Commands

CALCulate COMPareTYPE EQUalNEQual,@x COMPareTYPE? @x

CALCulate COMPareSTATe OFFON,@x COMPareSTATe? @x

CALCulate COMPareMASK COMPareMASK? @x

SENSeDIGitalDATABYTEWORD? @x

Digital Input Commands

See also Digital Input Operations in starting on

See also Totalizer Operations in starting on

Totalizer Commands

SENSe TOTalizeTYPE READRRESet,@x TOTalizeTYPE? @x

SENSeTOTalizeDATA? @x

Commands see Reading Format Commands on

SENSe TOTalizeSLOPe NEGativePOSitive,@x TOTalizeSLOPe? @x

SENSeTOTalizeCLEarIMMediate @x

SOURceDIGitalSTATe? @x

Digital Output Commands

DAC Output Commands

SOURce DIGitalDATABYTEWORD yvv ,@xt DIGitalDATABYTEWORD? @x

ROUTe Open @x OPEN? @x

Switch Control Commands

ROUTe CLOSe @x CLOSeEXCLusive @x CLOSe? @x

Zv z

ROUTe CHANnelFWIRe Offon , @ CHANnelFWIRe? @

ROUTeDONE?

SYSTemCPON 100200300ALL

RCL

State Storage Commands

SAV

MEMorySTATeDELete

MEMorySTATe Name 12345 ,z NAME?

MEMoryNSTates?

RECallAUTO?

MEMorySTATeVALid?

SYSTemTIME 3

System-Related Commands

SYSTemDATE 3 3yy

SYSTemDATE?

SYSTemCTYPe?

DIAGnostic Pokeslotdata 100200300, zyt PEEKSLOTDATA?

Oz v 7

DISPlayTEXTCLEar

DISPlay Offon DISPlay?

DISPlay Text zyt

Gfxz5

SYSTemPRESet

INSTrument DMM Offon

Fxz5

SYSTemVERSion?

SYSTemERRor?

Gzz xv v xz z Ud EC7N z vz5

Interface Configuration Commands

Gh6 Sy d

RS-232 Interface Configuration

RS-232 Interface Configuration

Gh6

Yzv Or xz xvwz

Gh6 Tyyy

Ud EC7N

For more information, see Flow Control Selection on

Modem Communications

Modem Communications

Zz yz

Ny yy gO

Scpi Status System

Ny y S gO

Ny yO

HP 34970A Status System

128

Bit Definitions Status Byte Register

Decimal Bit Number

Definition

Vvzz v xz Xzy wz zzx v gzv d5

Ghgf2 y

Gzv d zzxzy vz hzz3 yxv w gzv d xzv Yxvz vzx Xz5 iz z

S S

Ly QQm2

2048

Bit Definitions Questionable Data Register

512

1024

Scpi Status System

Bit Definitions Standard Event Register

Scpi Status System

Bit Definitions Alarm Register

Bit Definitions Standard Operation Register

Dy g

Gzz z wz vz 9CC z zz wz

Status System Commands

Status Byte Register Commands

Vv xzy xvz C z z Gv g fz5 fzzvz

STATusQUEStionableCONDition?

Status System Commands Questionable Data Register Commands

STATusQUEStionableENABle zv STATusQUEStionableENABle?

Gzz z wz vz 9D7 z zz wz

ESE zv

Status System Commands Standard Event Register Commands

Gzz z wz vz 9D9 z zz wz

STATusALARmENABle zv STATusALARmENABle?

Status System Commands Alarm Register Commands

STATusALARmCONDition?

STATusALARmEVENt?

STATusOPERationCONDition?

Status System Commands Standard Operation Register Commands

STATusOPERationENABle zv STATusOPERationENABle?

Gzz z wz vz 9DA z zz wz

PSC

Miscellaneous Status Register Commands

STATusPRESet

DATAPOINtsEVENtTHReshold t DATAPOINtsEVENtTHReshold?

CALibrationSECureCODE txyz

Calibration Commands

CALibration?

CALibrationCOUNt?

CALibrationVALue z CALibrationVALue?

CALibrationSECureSTATe OFFON,xyz CALibrationSECureSTATe?

CALibrationSTRing zyt

CALibrationSTRing?

DIAGnosticRELayCYCLes? @x

Service-Related Commands

DIAGnosticDMMCYCLes?

DIAGnosticDMMCYCLesCLEar

WAI

Preset state. h xy zz zzxPRESET z fxz5

Scpi gvyvy Py vw V is an

An Introduction to the Scpi Language

An Introduction to the Scpi Language

Syy i byy

Routchandelay 1TRIGSOUR EXT

Wvvxz

Fy h

HSeY Sy

HSeY ey

Channel list parameters specify one or

Hz ABORt x xyzy v vz v

Using Device Clear

Using Device Clear

Page

∙ x o u

Error

105

Execution Errors 101

102

103

124

Execution Errors 114j

121

123

213

Execution Errors 168

178

211

420

Execution Errors 230

310 350

410

203

Instrument Errors 111

201

202

251

Instrument Errors 221

225

226

281

Instrument Errors 261

271

272

307

Instrument Errors 303

305

306

512

Instrument Errors 501

502

511

604

Self-Test Errors

601 602

603

704

Calibration Errors

701

702 703

723

Calibration Errors 710 720

721

722

Error Messages

Page

BA8

Insert

G68

Example Programs for Excel

VISAaddr =

Excel 7.0 Example takeReadings Macro

BAB

BAC

Dim columnIndex As Integer

Excel 7.0 Example ScanChannels Macro

BAF

BAG

Ck qdnT User’s Guide6

Example Programs for C and C++

Ck qdnT User’s Guide6 o

++ Example dacout.c

++ Example statreg.c

BB9

Page

AG=

ABA

AFF

AG8

Uzz

System Cabling and Connections

Lz k

Gz bz 0z

Cable Type Nominal Impedance Capacitance Attenuation

99=

LvLv

3uqyu

Copper-to

Uj m

GxuuB

Gxuyw qs u

Z Uff4 Refer to Measurement Input on

Wuq

Measurement Fundamentals

Integration Time PLCs

Wsu

Qysq Dxu qsuvqsu ytu qsusyvysq Vq tu4

Bz mz 9GG8

Measurement Fundamentals

Internal DMM

Internal DMM Ice Bath

Ez b

Measurement Fundamentals

Copper Constantan

Temperature Probe Type Pos + Lead Neg Lead

Iron Constantan

Nickel-Chromium Nickel-Aluminum

Z4 z

ABC

MWW2

99A

Nm w

Stuqq

Connection a Connection B

Sl py

Sk p j

HI A1 AC to DC Converter X10 X100

360

361

Km w

Example Calculating Measurement Error

N5zzz z5 z z 0 z AAD16

Hj s

Voltage Measured = ‾‾‾‾‾‾‾‾‾‾‾‾√ V 2 + Noise

MWW

On-Card

Km m

Nm m

To Amplifier Analog-to-Digital Converter

HI-Source HI-Sense

Does not sxqu

For more information on channel delay, see

AB8

Offset Compensation on page 115 for more information

Insulating Material Resistance Range Moisture Absorbing

Zz4 z FF

Ai Sz e

HI Source HI Sense LO Sense LO Source

Strain DMM Sensitivity

376

Measurement Fundamentals

V3Vu cyw Wuy q cyxy

Low-Level Signal Multiplexing and Switching

4 AC8

ELo

HI + Source Sense

OUT COM H GND COM L

Zz AE

Module Bank

Module Reference

Actuators and General-Purpose Switching

Rp =

Dxu q u Ytu u qt Dxuuvu2 xu yy b Sq ru t qB

Module Reference

Wqy cyxy

Matrix Switching

Matrix Module

BO cyw

RF Signal Multiplexing

9A7

Multifunction Module

393

= 24 k Ω

GND TTL AC

For more information on cabling noise, see

R B8 R URT z16 ∙ d qy s2 u .b Yu tyqwq Qr/ w

EnkmF y

U55R

Nkm o

Buq Z

Relay Life and Preventative Maintenance

Qsuqsu wuqq

Uu utysuqqy4

AOT

AHe

AHf

AOO

DC Voltage

DC, Resistance, and Temperature Accuracy Specifications

Ki u y

DC Measurement and Operating Characteristics

Gi g

AC Accuracy Specifications

Gi u

AC Measurement and Operating Characteristics

Single Channel Measurement Rates 1 System Characteristics

Measurement Rates and System Characteristics

TagHOr7 TagHPr7 TagHfr7 TagHTr7 TagHar

Module Specifications

TagHcr7 TagHdr

Typical AC Performance Graphs

TagHer

Product and Module Dimensions

Understanding the % of reading Error o

To Calculate Total Measurement Error

× 1,000,000

Understanding the % of range Error o

Interpreting Internal DMM Specifications

Criteria

417

LYR u

BdR u

Vhh 87 b 87 q ∙ p =4 ∙ n ∙ n c 77 =8F

Configuring for Highest Accuracy Measurements

Index

Index

CAB

CAC

CAD

CAE

CAF

CAG

CAH

CB8

CB9

CBA

CBB

Declaration of Conformity

Ajjh