13.3Unconditional Restart of Automatic Operation

The cases below refer to the axes in the selected plane in when offset mode is on. To interrup- tion of axis movements outside the selected plane refer to interruption cases in state G40.

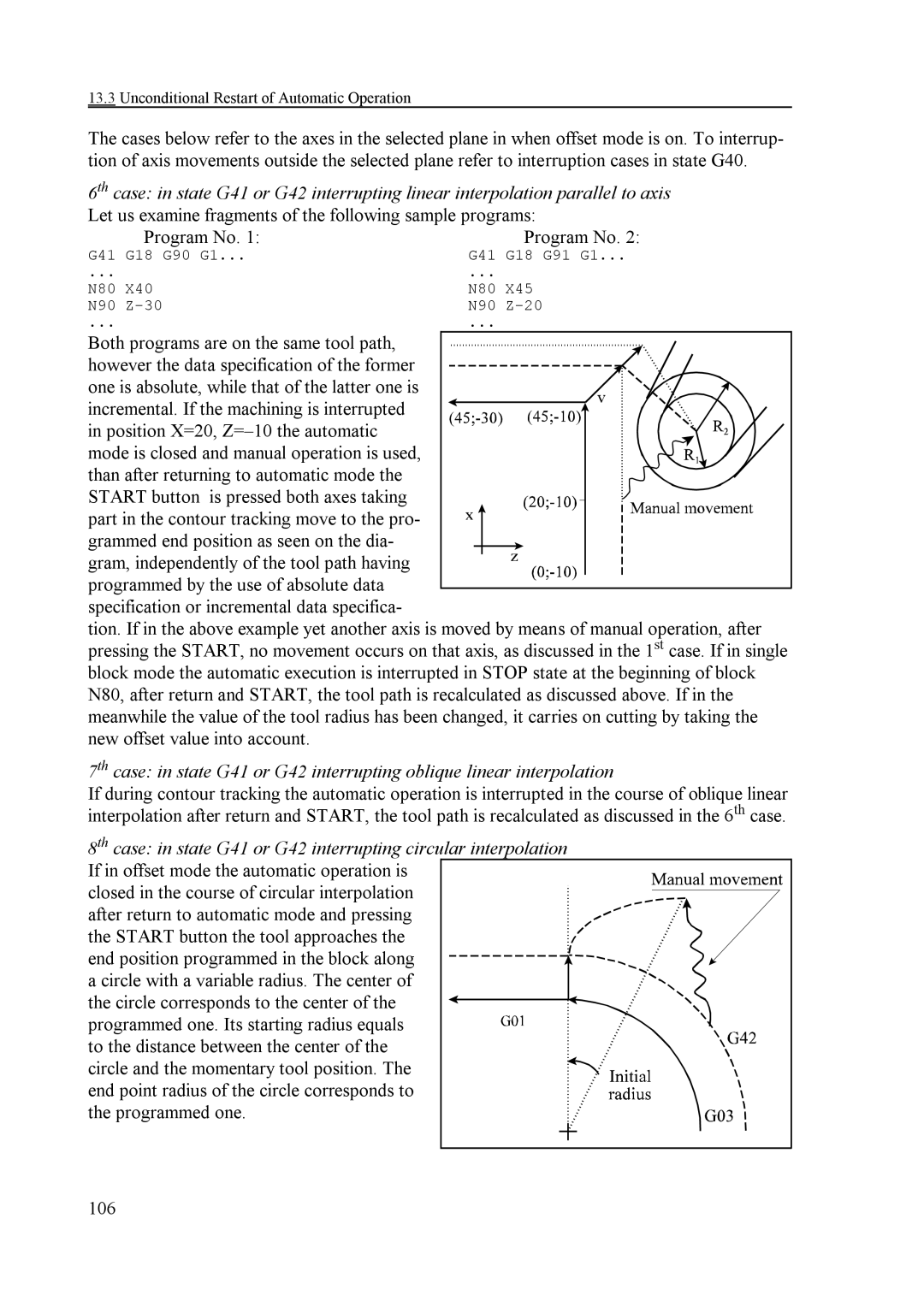

6th case: in state G41 or G42 interrupting linear interpolation parallel to axis Let us examine fragments of the following sample programs:

G41 | Program No. 1: | G41 | Program No. 2: | ||

G18 | G90 G1... | G18 | G91 G1... | ||

... | X40 |

| ... | X45 |

|

N80 |

| N80 |

| ||

N90 |

| N90 |

| ||

... |

|

| ... |

|

|

Both programs are on the same tool path,

however the data specification of the former

one is absolute, while that of the latter one is incremental. If the machining is interrupted

in position X=20,

START button is pressed both axes taking

part in the contour tracking move to the pro- grammed end position as seen on the dia-

gram, independently of the tool path having programmed by the use of absolute data specification or incremental data specifica-

tion. If in the above example yet another axis is moved by means of manual operation, after pressing the START, no movement occurs on that axis, as discussed in the 1st case. If in single block mode the automatic execution is interrupted in STOP state at the beginning of block N80, after return and START, the tool path is recalculated as discussed above. If in the meanwhile the value of the tool radius has been changed, it carries on cutting by taking the new offset value into account.

7th case: in state G41 or G42 interrupting oblique linear interpolation

If during contour tracking the automatic operation is interrupted in the course of oblique linear interpolation after return and START, the tool path is recalculated as discussed in the 6th case.

8th case: in state G41 or G42 interrupting circular interpolation If in offset mode the automatic operation is

closed in the course of circular interpolation after return to automatic mode and pressing the START button the tool approaches the end position programmed in the block along a circle with a variable radius. The center of the circle corresponds to the center of the programmed one. Its starting radius equals to the distance between the center of the circle and the momentary tool position. The end point radius of the circle corresponds to the programmed one.

106