7.2.1Work Zero Point Offset Measurement

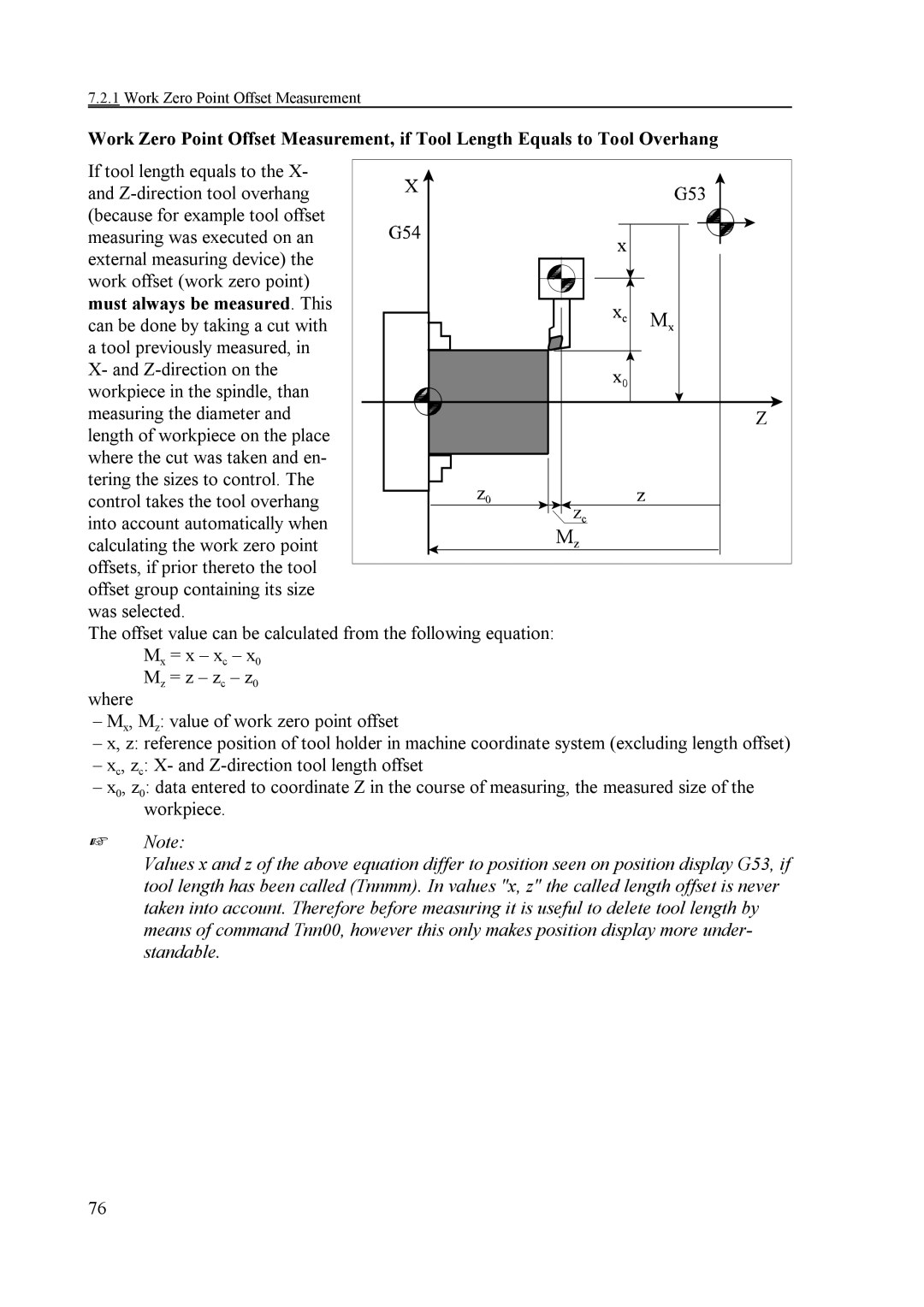

Work Zero Point Offset Measurement, if Tool Length Equals to Tool Overhang

If tool length equals to the X-

and

work offset (work zero point) must always be measured. This

can be done by taking a cut with a tool previously measured, in X- and

workpiece in the spindle, than measuring the diameter and

length of workpiece on the place where the cut was taken and en- tering the sizes to control. The

control takes the tool overhang into account automatically when calculating the work zero point offsets, if prior thereto the tool

offset group containing its size was selected.

The offset value can be calculated from the following equation: Mx = x – xc – x0

Mz = z – zc – z0

where

–Mx, Mz: value of work zero point offset

–x, z: reference position of tool holder in machine coordinate system (excluding length offset)

–xc, zc: X- and

–x0, z0: data entered to coordinate Z in the course of measuring, the measured size of the workpiece.

LNote:

Values x and z of the above equation differ to position seen on position display G53, if tool length has been called (Tnnmm). In values "x, z" the called length offset is never taken into account. Therefore before measuring it is useful to delete tool length by means of command Tnn00, however this only makes position display more under- standable.

76