12 Debugging Part Program

12 Debugging the Part Program

The following functions help the testing, debugging of the part program:

–single block execution,

–dry run,

–locking possibilities and

–test run.

These functions are not operation modes, but conditions influencing the program execution in automatic mode.

12.1 Single Block Execution

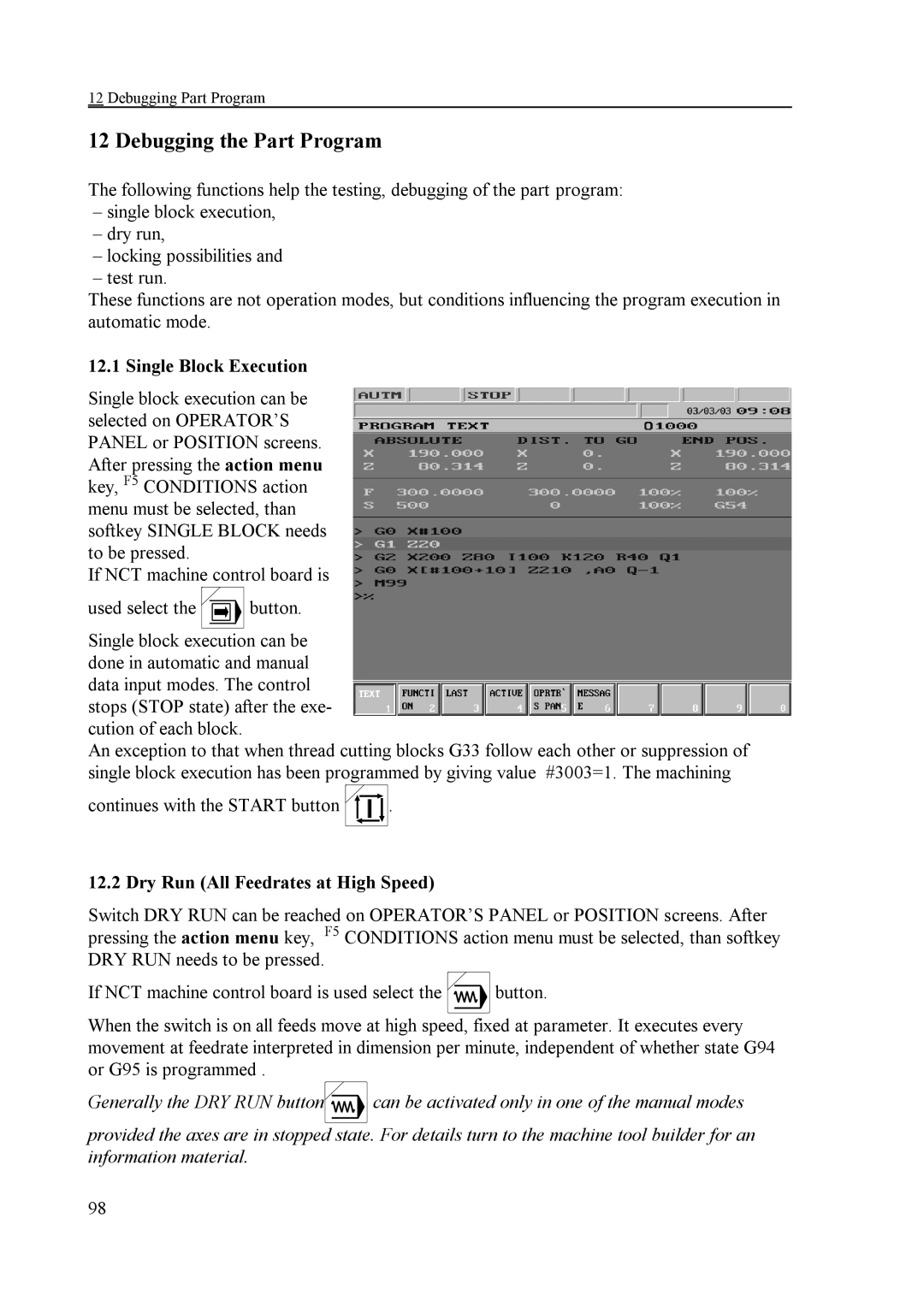

Single block execution can be selected on OPERATOR’S PANEL or POSITION screens. After pressing the action menu key, F5 CONDITIONS action menu must be selected, than softkey SINGLE BLOCK needs to be pressed.

If NCT machine control board is

used select the ![]()

![]()

![]()

![]() button.

button.

Single block execution can be done in automatic and manual data input modes. The control stops (STOP state) after the exe- cution of each block.

An exception to that when thread cutting blocks G33 follow each other or suppression of single block execution has been programmed by giving value #3003=1. The machining

continues with the START button ![]()

![]()

![]()

![]()

![]() .

.

12.2 Dry Run (All Feedrates at High Speed)

Switch DRY RUN can be reached on OPERATOR’S PANEL or POSITION screens. After pressing the action menu key, F5 CONDITIONS action menu must be selected, than softkey DRY RUN needs to be pressed.

If NCT machine control board is used select the ![]()

![]() button.

button.

When the switch is on all feeds move at high speed, fixed at parameter. It executes every movement at feedrate interpreted in dimension per minute, independent of whether state G94 or G95 is programmed .

Generally the DRY RUN button![]() can be activated only in one of the manual modes

can be activated only in one of the manual modes

provided the axes are in stopped state. For details turn to the machine tool builder for an information material.

98