NCT 100T NCT 990T NCT 2000T

Mailnct@nct.hu

Contents

Intervention in the Course of Program Execution

Interruption and Restart of Automatic Operation

Page

Conditions of Operation and Storage

Introduction

NC Control Panel Display Unit and Data Input Keyboard

Operator’s Panel

Operator’s Panel

Backspace

Data Input Keyboard

Screen menu key

Action menu key

PgDn

State of First Operation Mode Group

State of Second Operation Mode Group

Keys PgUp

PLC State

Functional State of Automatic and Manual Data Input

Program Manipulation State

Interpolator State

Machine Control Board

Indication of Ready Status of Control

Operation mode selectors

Increment selectors

Override switches

Switches modifying the conditions of program execution

Automatic Manual data input

Movement, start and stop buttons

Block restart Block return Function lock

General Operating Knowledge

Screen Menu

Position

Graphics

Check

Program

Offsets

Action Menu

Setting

Service

#100

General Operating Knowledge

General Displaying Areas and Actions Executed on Them

Position Screens

Actions of Position Screens

Check Screens

Program Text Screen, Listing of Running Program

Function Screen, Subprogram and Macro Levels

Actions of sreens Program TEXT, FUNCTION, Last and Active

Last and Active screens. G Codes and Compensations

OPERATOR’S Panel Screen

Actions of OPERATOR’S Panel Screen

Key

Actions

Operation Modes Actions Modes

Axes Actions

Increment Actions Incr

Messages Screen

Clear Relative Position Actions Clear Relpnt

Actions of Directory Screen

Program Screens

Screens of actions executed on part programs

Directory Screen

Program Screens

Actions of View Screen

View Screen

Actions of Edit Screen

Edit Screen

Actions of Block Input Screen

Block Input Screen

Offsets Screens

Work Offsets Screen

Actions of Work Offsets Screen

Tool Offsets Screen

Actions of Tool Offsets Screen

Keys This bar selects the offset register to be modified

Offsets Screens

Actions of Work Offset Measure Screen

Work Offset Measure Screen

Actions of Tool Length Offset Measure Screen

Tool Length Offset Measure Screen

Actions of Relative Position Offsets Screen

Relative Position Offsets Screen

Graphic Parameters Screen

Graphic Position Screens

Actions of Graphic Parameters Screen Color Code

Actions of Draw Screen

Draw Screen

Graphic Position Screens

Setting Screens

Screen of Local Macro Variables #1-#33

Actions of Local Macro Variables #1-#33 Screen

Actions of Common Macro Variables #100-#199 Screen

Screen of Common Macro Variables #100-#199

Actions of Common Macro Variables #500-#599 Screen

Screen of Common Macro Variables #500-#599

Timer and Counter Screen

Actions of Timer Counter Screen

Tool POT Table Screen

Actions of Tool POT Table Screen

Actions of PLC Table Screen

PLC Table Screen

Actions of USER’S Parameters Screen

USER’S Parameters Screen User’s Params

Security Panel Screen

Generated code, or PLC key

Fix code, or PLC key

Below table contains the codes of the appropriate functions

Setting Screens

Structure of Part Program

Editing Part Programs

Beginning and end of program

Division of Edit Screen during Editing

Typing

Moving the cursor

Selected text is deleted by means of key del

Insert

Edit

Editor Action Menu

File Actions Save, Save as

Edit Actions Undo, Cut, Copy, Paste, Find and Replace

Editing part programs

Insert Operation Action Group

Insert Actions

Insert Miscellaneous Action Group

Insert Condition Action Group

Help

Tion menu key

Switching Over Operation Modes

Manual Reference Point Return Mode

Manual Operation Modes

Axis Selection

Types of Reference Point Return

Feedrate Selection

Jog Mode

Jog Mode

Increment Selection

Incremental Jog Mode

Incremental Jog Mode

Manual Handle Mode

Speed

Actions Executed in Manual Operation Modes

Single Block Operation

Work Zero Point Offset and Tool Length Offset Measurement

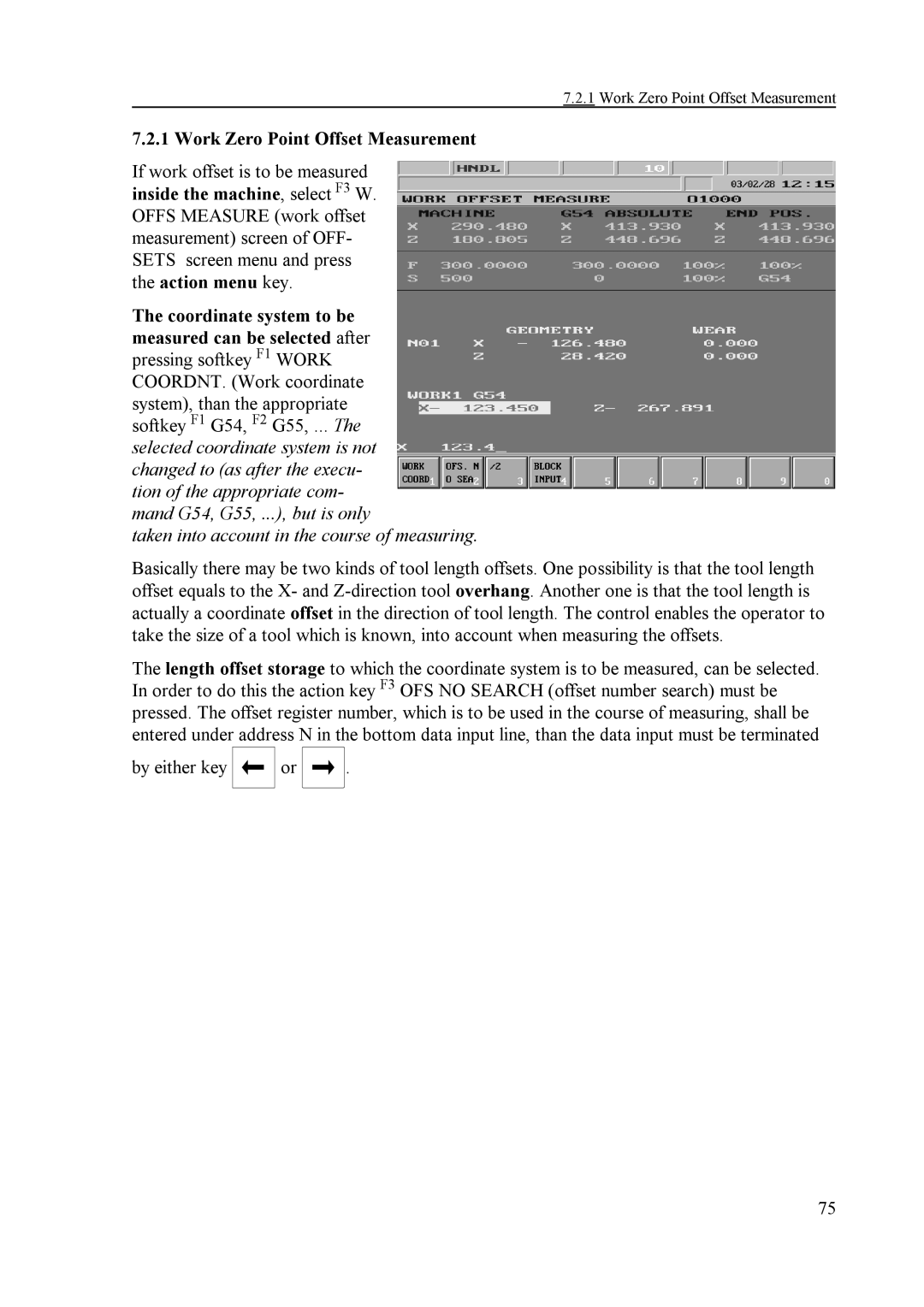

Coordinate system to be measured can be selected after

Work Zero Point Offset Measurement

Work Zero Point Offset Measurement

Work Zero Point Offset Measurement

Tool Length Offset Measurement inside the Machine

Tool Length Offset Measurement inside the Machine

CONTACTX+ Contactx CONTACTZ+

Automatic Tool Length Offset Measurement

Calibrating Tool Offset Sensor

Calibrating the Sensor to the Coordinate System of Chuck

Calibrating the Sensor to Reference Point

Procedure can also be applied for the other buttons

Automatic Mode

Modes of Automatic Operation

Program Execution in DNC

Machining Start and Stop

Editing Programs under Automatic Execution

Edit Mode

Differences between Automatic and Manual Data Input modes

Manual Data Input Mode

Manual Data Input Mode

Feedrate Override Switch

Override Switches

Spindle Speed Override Switch

Rapid Traverse Override Switch

Override Switches

Feed Stop

Reset

Program Execution Start and Stop

Starting Program Execution

Conditional Stop M01

Programmed Stop M00

End of Program M02, M30

Intervention in the Course of Program Execution

Conditional Block Skip

Increasing Feedrate by Means of Rapid Traverse Jog Button

Rules of operation are as follows

Effect of intervention to coordinate system

Debugging the Part Program

Single Block Execution

Dry Run All Feedrates at High Speed

Axis Lock

Machine Lock Function

Other Locking Possibilities

Function Lock

Test Run

Interruption of Automatic Operation

Interruption and Restart of Automatic Operation

Is displayed Y=yes. By pressing Shift key question

Restore Modal FUNCTIONS? N

Unconditional Restart of Automatic Operation

Interrupting Single Blocks

Program No

Interrupting Canned Cycles

105

Interrupting Machining in Offset Mode

G41

Unconditional Restart of Automatic Operation

Automatic Operation Restart with Block Restart Condition

Return to Block Start Position in Automatic Mode

Automatic Operation Restart with Block Restart Condition

Automatic Operation Restart with Block Restart Condition

Block Restart

Return to the Interruption Point in Automatic Operation

Automatic Mode Restart with Block Return Condition

Cases of Return by Means of Condition Block Return

Automatic Mode Restart with Block Return Condition

Return

When condition Block

If F4 Block Search action is selected after pressing action

Automatic Operation Start after Block Search

Command Search

Number of Tool to be Change d T1

117

Positions

Spindle Rotation Code M3

Coolant Code M8

Other Functions M

Command Goto

Other Intervention Possibilities Before Start

Search for Interrupted Block

120

Global Messages

Listing of Messages and their Codes

There may be two types of messages Local and global

Local Message

Messages of custom macros

123

Listing of Global Messages

124

125

126

127

128

129

130

131

132

133

134

135

136

137

3104

138

3102

3103

139

140

141

142

143

Alphabetical index

ENCODERn 124

FEEDBACKn 124

![]()

![]()

![]() .

.